Manufacturing method of 18ch-high-isolation dense wavelength division multiplexing products with

A dense wavelength division multiplexing and production method technology, which is applied in the production of 18ch high-isolation dense wavelength division multiplexing products, can solve the problems of transmission capacity and expansion methods that cannot meet the demand, and the huge bandwidth resources of optical fibers are not fully utilized. Achieve the effect of improving transmission capacity, improving frequency selection characteristics, and reducing mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easy to understand, the specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

[0014] A method for manufacturing an 18ch high-isolation dense wavelength division multiplexing product, comprising the following steps:

[0015] (1) Prepare raw materials, process equipment and testing equipment;

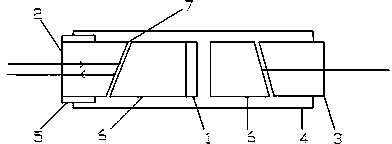

[0016] (2) Use glue 7 to connect the double-fiber head 2 and the single-fiber collimator 3, then stick the small glass tube 5 on both sides of the double-fiber head 2, and stick the large glass tube 4 to the single-fiber collimator 3;

[0017] (3) Finally, glue the G-Lens lens 6 and the filter 1 on the device, and complete the device assembly after the glue dries.

[0018] Furthermore, the raw materials described in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com