Punching robot production control system

A technology of production control and robotics, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as poor flexibility, and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

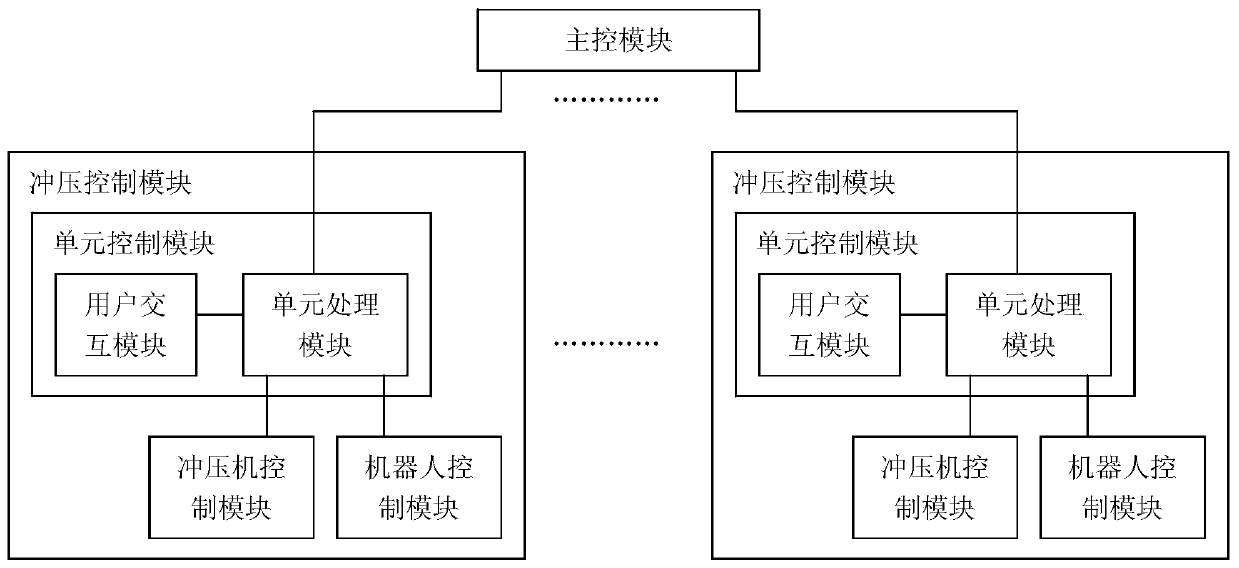

[0022] In the stamping robot production control system in this example, the stamping control module is composed of the unit control module, the robot control module and the stamping machine control module. The system block diagram is as follows figure 1 .

[0023] The stamping robot production control system is specifically composed of a main control module and at least one stamping control module. The stamping control module is connected to the main control module. Acquisition, in which the main control module is used to collect operating signals from the stamping control module, and monitor the working conditions of the stamping control module and the controlled robot connected to it and the stamping machine in real time; the stamping control module is used to receive user input control, and control according to user input The controlled robot and stamping machine connected to it form a production line, and the working status of the controlled robot and stamping machine conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com