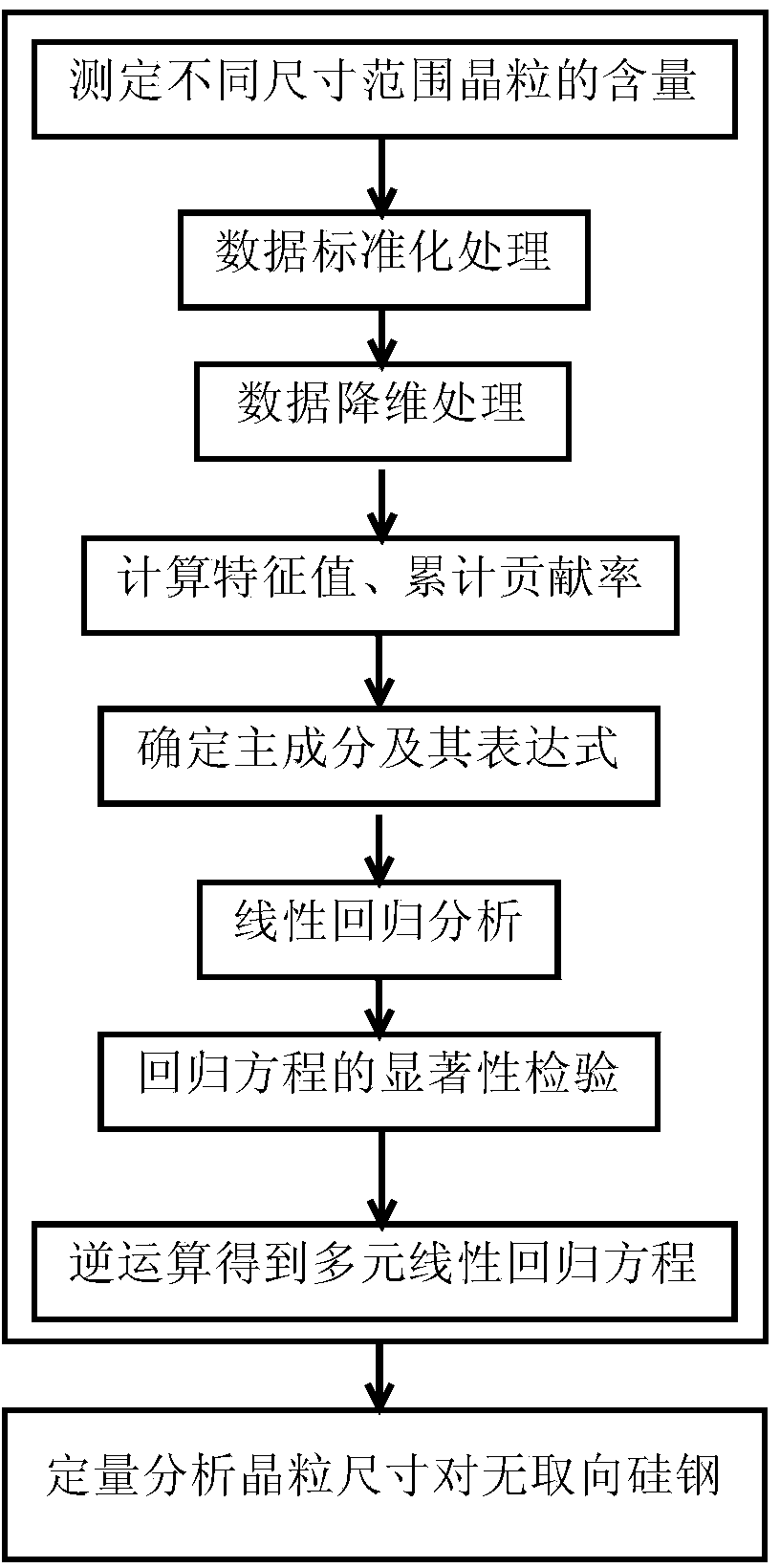

Method for analyzing influences of grain sizes on magnetic performance of non-oriented silicon steel on basis of principal components regression analysis

A principal component regression, oriented silicon steel technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of revealing the relationship between grains of different sizes and the magnetic properties of non-oriented silicon steel, which is rare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained and illustrated below in conjunction with the embodiments and accompanying drawings.

[0035] The embodiment adopts the non-oriented silicon steel product test samples provided by a steel factory after continuous casting, hot rolling (2.6mm thick), cold rolling (0.5mm thick), continuous annealing and surface coating, and selects 10 groups of magnetic properties. Different samples were studied, and the magnetic properties of each group of samples are shown in Table 2.

[0036] The magnetic property of table 2 embodiment sample

[0037]

[0038]

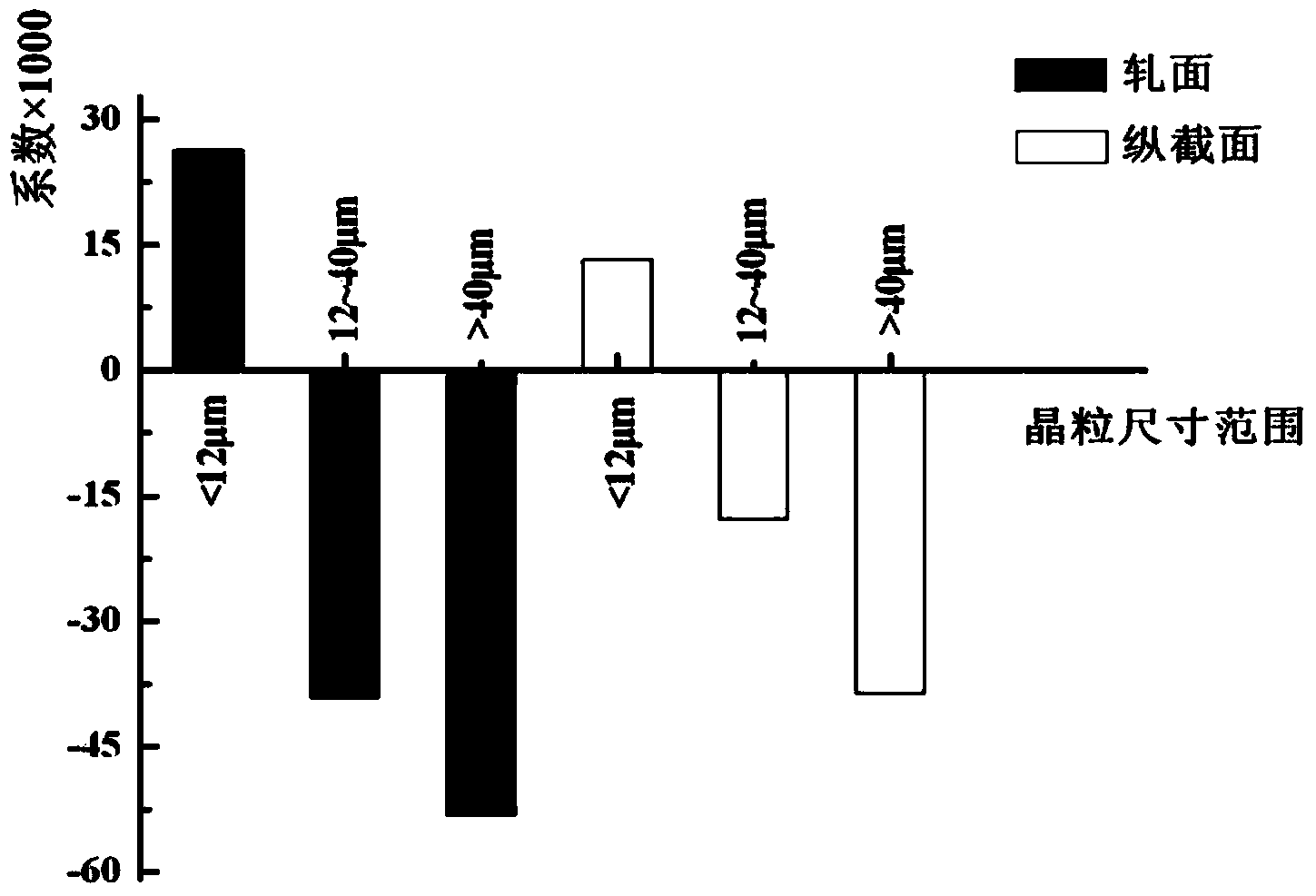

[0039] Use the EBSD system of ZEISSULTRA55 field emission scanning electron microscope and Channel5 orientation analysis software to measure the content of grains in different size ranges of statistical samples. The observation surface of the sample is divided into rolled surface and longitudinal section, at 100 to 200 times, preferably 100 times the field of view In this ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com