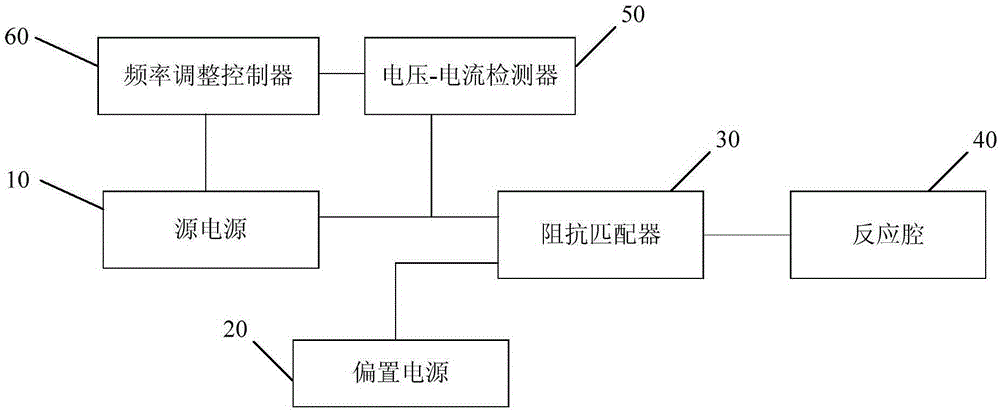

Impedance Matching Method for Plasma Etching System

An etching system and plasma technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problems of low efficiency of frequency modulation algorithm and inability to find matching frequency automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] According to the background art, the efficiency of impedance matching of the plasma etching system in the prior art is low.

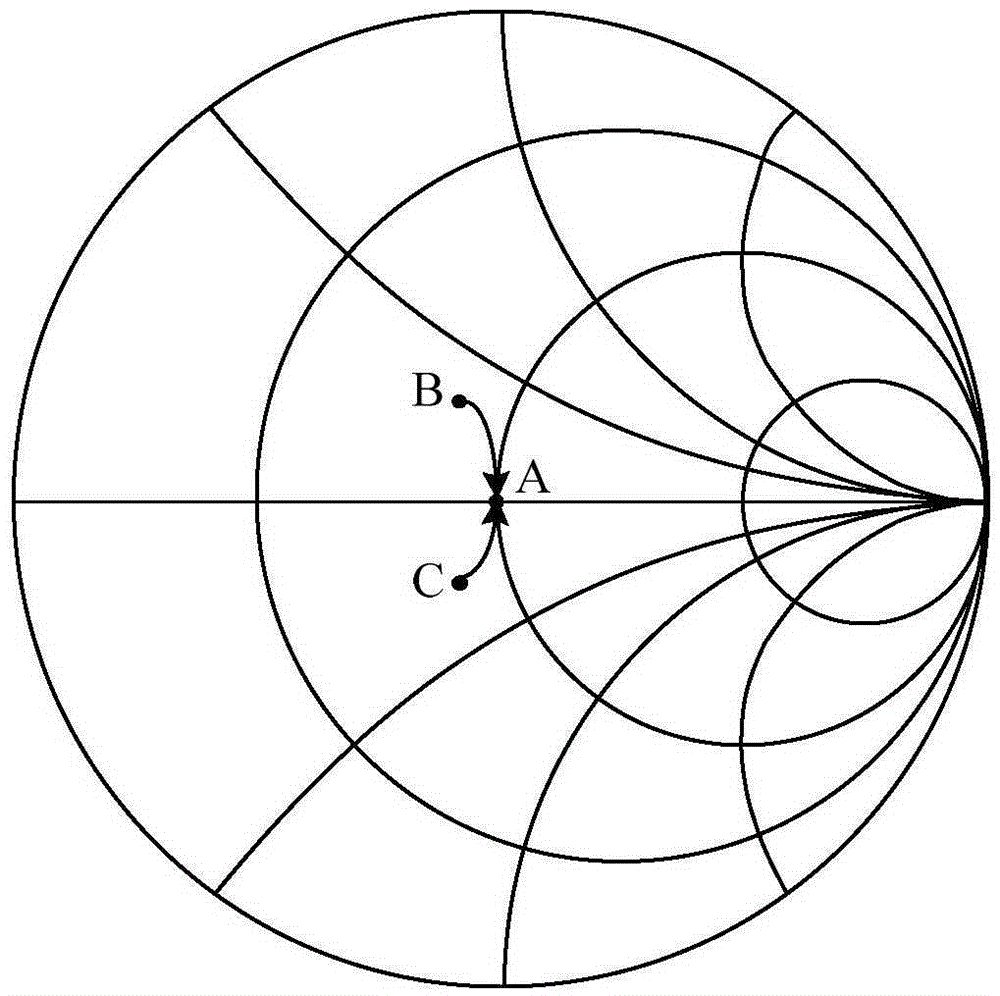

[0028] Since the source power is used to generate plasma in the reaction chamber, the frequency of the source power has a greater impact on the impedance of the plasma, while the frequency change of the bias power has little effect on the impedance of the plasma, so it can be adjusted The frequency of the source power supply finds a suitable matching frequency to achieve impedance matching.

[0029] Because the bias power supply is in the pulse-on and pulse-off states, the impedance of the system is quite different. At the moment when the bias power is switched from the pulse-on state to the pulse-off state, the impedance at the output end of the impedance matcher will change, which will cause the reflection coefficient of the power supply to increase, which will trigger the coarse adjustment of the source power frequency, which will lead to the whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com