An electronic device housing, a manufacturing method thereof and an electronic device with the housing

A technology of electronic equipment and manufacturing method, which is applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, casing/cabinet/drawer parts, etc., which can solve the problems of difficult to obtain appearance and cost increase, and is not easy to achieve Effects of falling off, improving strength, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

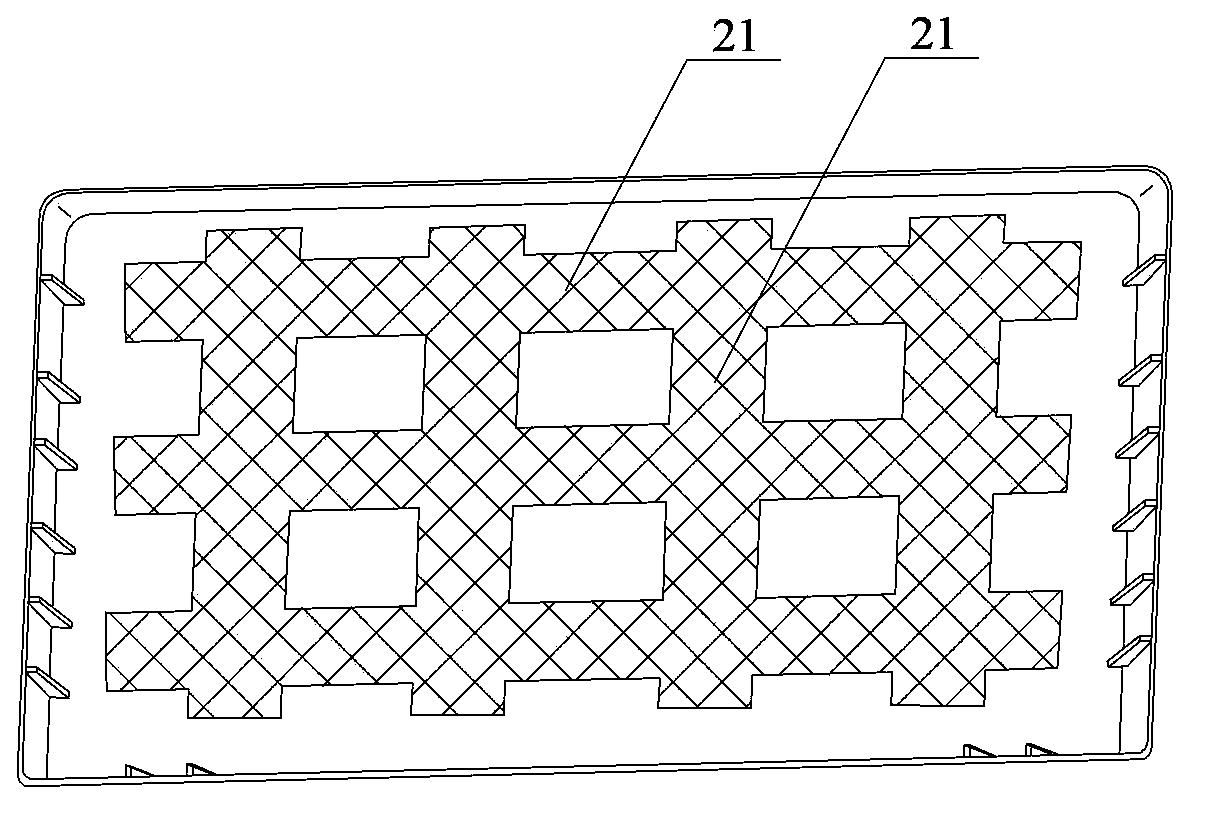

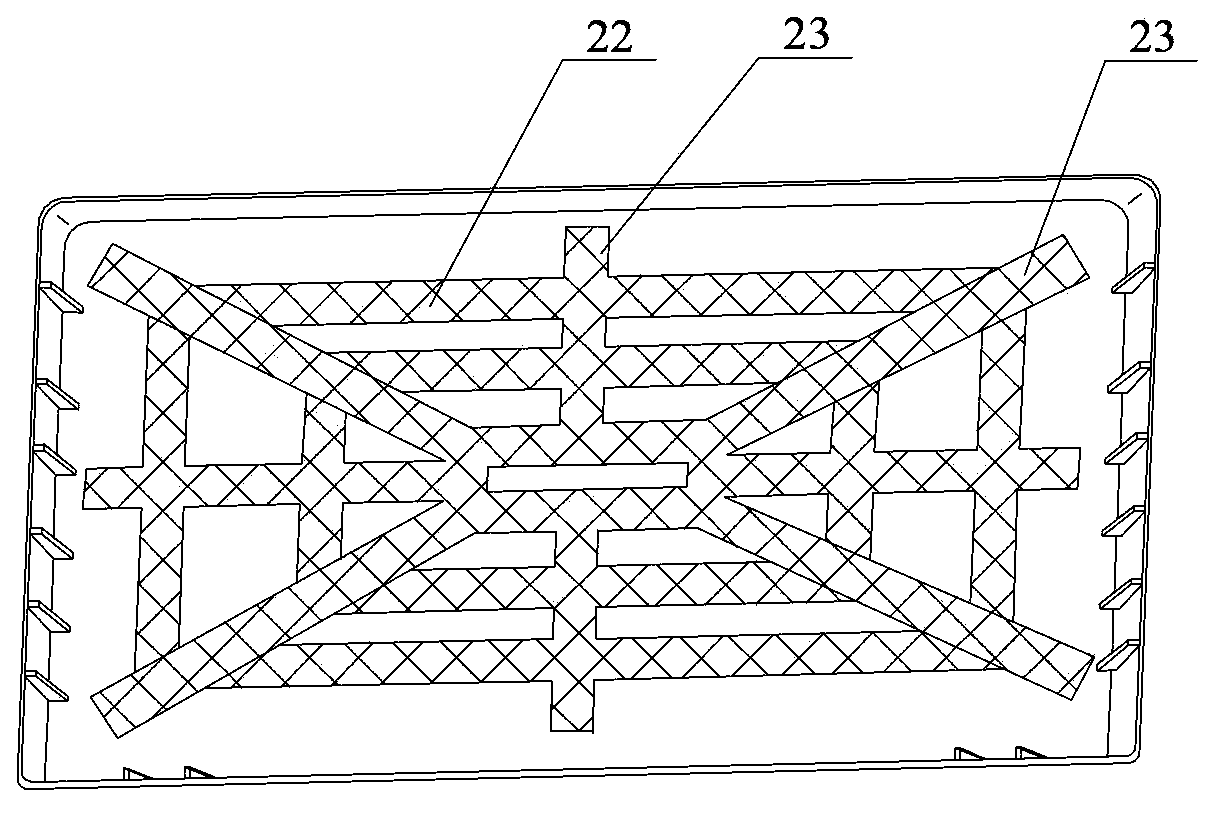

[0044] The core of the present invention is to provide an electronic device casing, a reinforcing sheet with a hardness greater than that of the casing body is attached and fixed on the inner surface of the bottom wall of the casing body, which greatly improves the strength of the electronic device casing and can The liquid crystal screen and other components in the casing are effectively protected, and the casing has a thinner bottom wall, and the cost is also lower. The specific embodiment will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can better understand.

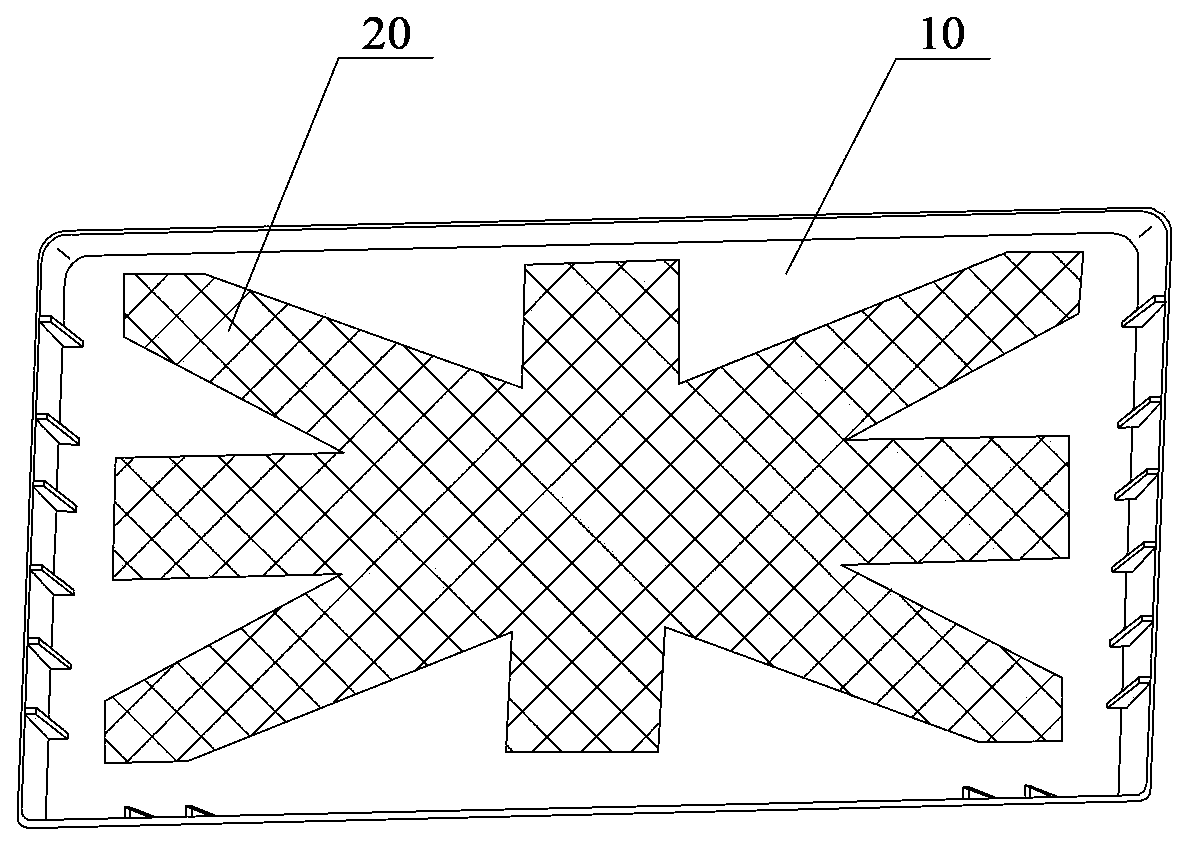

[0045] See figure 1 , which is a schematic structural diagram of the housing of the electronic device described in this embodiment.

[0046] What this figure shows is a display screen rear shell of a notebook computer. Obviously, the technical solution provided by the present invention is not only applicable to the display screen rear shell of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com