A device for cutting honey caps

A honey cap and steam technology, applied in the field of honey cap cutting, can solve the problems of destroying the integrity of honey cap, easy mixing of honey cap, difficulty in purifying honey and cap wax, etc., so as to reduce the quality change of honey, reduce the burden and increase the Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

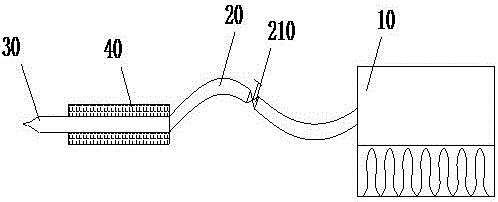

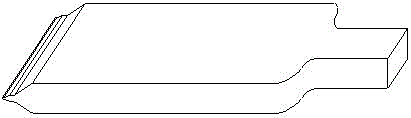

[0015] Such as Figure 1~2 As shown, the specific embodiment of the present invention is: a method for cutting honey caps, which is characterized in that the wax caps on the honeycombs are melted instantaneously at high temperatures, so that the beeswax naturally gathers at the mouth of the honeycomb under the effect of surface tension. The wall of the house to achieve honey extraction.

[0016] In the present invention, the best high-temperature temperature of the honey-cutting cap used is 80-200°C, which can ensure the melting of the honey cap wax at this temperature, and has a certain killing effect on the microorganisms attached to the surface of the honey spleen. At the same time, it will not The quality of honey is affected by high temperature.

[0017] The present invention also designs a device for cutting honey caps, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com