Special spray head for cleaning of towers

A nozzle and tower technology, applied in the field of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

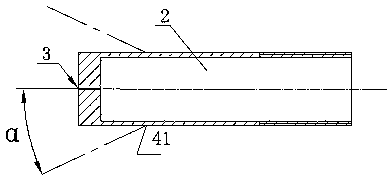

[0014] In order to solve the above technical problems, the present invention provides a special nozzle for tower cleaning, including a nozzle body 1, the nozzle body 1 is a cylinder, a through hole 2 is arranged in the nozzle body 1 along the axial direction, and the nozzle body 1 One end of the nozzle is provided with a nozzle hole 3, and the water flow can be sprayed from the nozzle hole 3 while maintaining high pressure, and the other end is connected with the spray gun rod, and the through hole 2 communicates with the spray gun rod; the nozzle body 1 is a cylinder made of alloy steel Cr 67 , which has an outer diameter of 16mm, a length of about 6cm, and an inner diameter of 14mm. Nozzles 41 are respectively provided on the outer walls of the two sides of the shower head body 1. The number of nozzles 41 is not limited, and can be two, four, six or more. The nozzles are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com