Water bag type pressure adjusting device and pressure adjusting method

A technology of pressure regulating device and water stop device, which is applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of high pressure and easy damage, and achieve the effect of simplifying the construction process and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

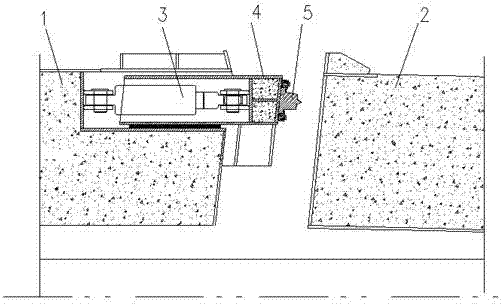

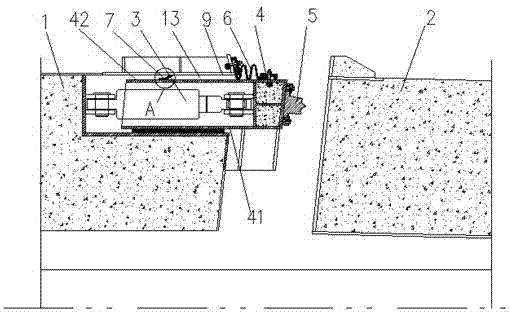

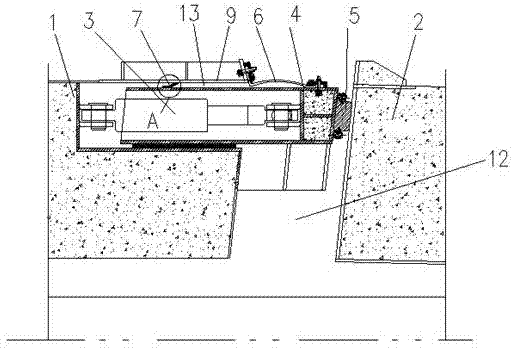

[0057] like figure 2 and image 3 As shown, the water bladder pressure regulating device includes a push beam 4 arranged in the groove of the final joint 1. The push beam 4 is a closed ring structure, and the push beam 4 is connected to the final joint 1. The end of the first water stop system 6 is installed, and the gap between the pushing beam 4 and the final joint 1 is also provided with a second water stop system 7, so that the first water stop system 6 and the second water stop system An annular water bag 13 can be formed between the 7, and the second water stop system 7 is a one-way water stop device.

[0058] During the sinking process of the final joint 1, the groove of the final joint 1 is filled with seawater, so that the pressure on both sides of the first water stop system 6 is the same, and the first water stop system 6 is not stressed. After adjusting the position of the final joint 1 in place, push the small beam 4, so that the joint cavity 12 between the fin...

Embodiment 2

[0078] This embodiment provides a method for installing a one-way water stop device as the second water stop system, so that the water bag type pressure regulating device formed by the first water stop system and the second water stop system is as follows: figure 2 and image 3 shown, including the following steps:

[0079] a. Install the first water stop system 6 and the second water stop system 7 in advance;

[0080] b. Put the final joint 1 in place as a whole, and adjust it in place. The water flows into the annular water bag 13 through the second water stop system 7, so that the water bag 13 is filled with water;

[0081] c. Push the trabecular 4 to push, and drive the Gina waterstop 5, the first waterstop system 6 and the second waterstop system 7 to move together until the Gina waterstop 5 is fully compressed to the end face of the adjacent pipe joint 2 , the final joint 1 and the adjacent pipe section 2 form a joint cavity 12;

[0082] d. The combination cavity 12 dr...

Embodiment 3

[0085] This embodiment provides a pressure regulating method for a water bag type pressure regulating device with a ventilation device. Specifically, an exhaust pipe 10 with a cock 11 is installed on the push beam 4, and the two ends of the exhaust pipe 10 are respectively located at In the combination cavity 12 and the water bag 13, the communication state of the combination cavity 12 and the water bag 13 is controlled by the cock 11, such as figure 2 and image 3 shown, including the following steps:

[0086] a. Install the first water stop system 6, the second water stop system 7 and the exhaust pipe 10 in advance, the cock 11 of the exhaust pipe 10 is in an open state, so that the combination chamber 12 and the water bag 13 are in a connected state;

[0087] b. Put the final joint 1 in place as a whole, and adjust it in place. The air in the water bag 13 is discharged through the exhaust pipe 10, and at the same time, the water flows into the annular water bag 13 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com