Full-mold casting method of resin sand without vent hole

A solid casting technology without vent holes, applied in casting molding equipment, casting molds, cores, etc., can solve problems such as restricting enterprise development, environmental pollution, and increasing production costs, avoiding safety accidents, and improving slag retention. effect, to ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail:

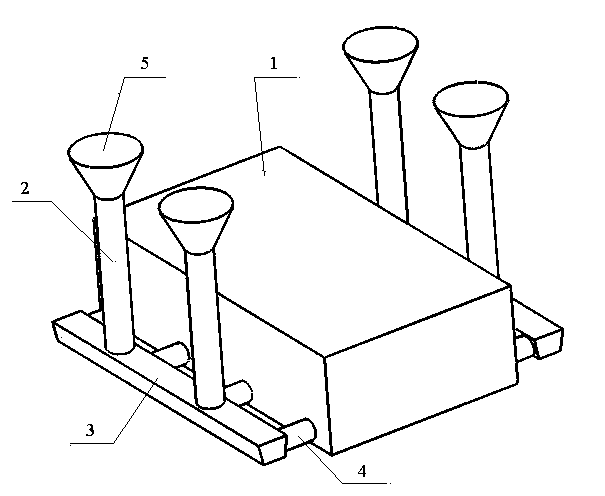

[0022] The invention discloses a resin sand solid mold casting method without air holes, which includes the steps of making pattern and pouring system, molding, smelting and pouring, molding sand cleaning and the like. In this embodiment, the full mold casting method of machine tool castings is taken as an example. The finished shape of the machine tool castings is a cuboid frame with a length of 15m, a width of 3.2m and a height of 2.1m, and the weight of the casting is 83t.

[0023] According to the pattern of the finished casting, the shape of the pattern is the same as that of the finished casting, and the machining allowance set on the processing surface of the finished casting is 20mm. In order to ensure the quality of the casting product, when making the pattern, the upper surface of the pattern is preset with a certain thickness of machining allowance for collecting resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

| Short axis | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com