Adjustable spiral drill jig

An auger drill and adjustable technology, which is applied in the direction of drilling templates for workpieces, can solve the problems of low efficiency and poor precision of manual drilling, and achieve the effects of easy loading and unloading, liberating labor and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

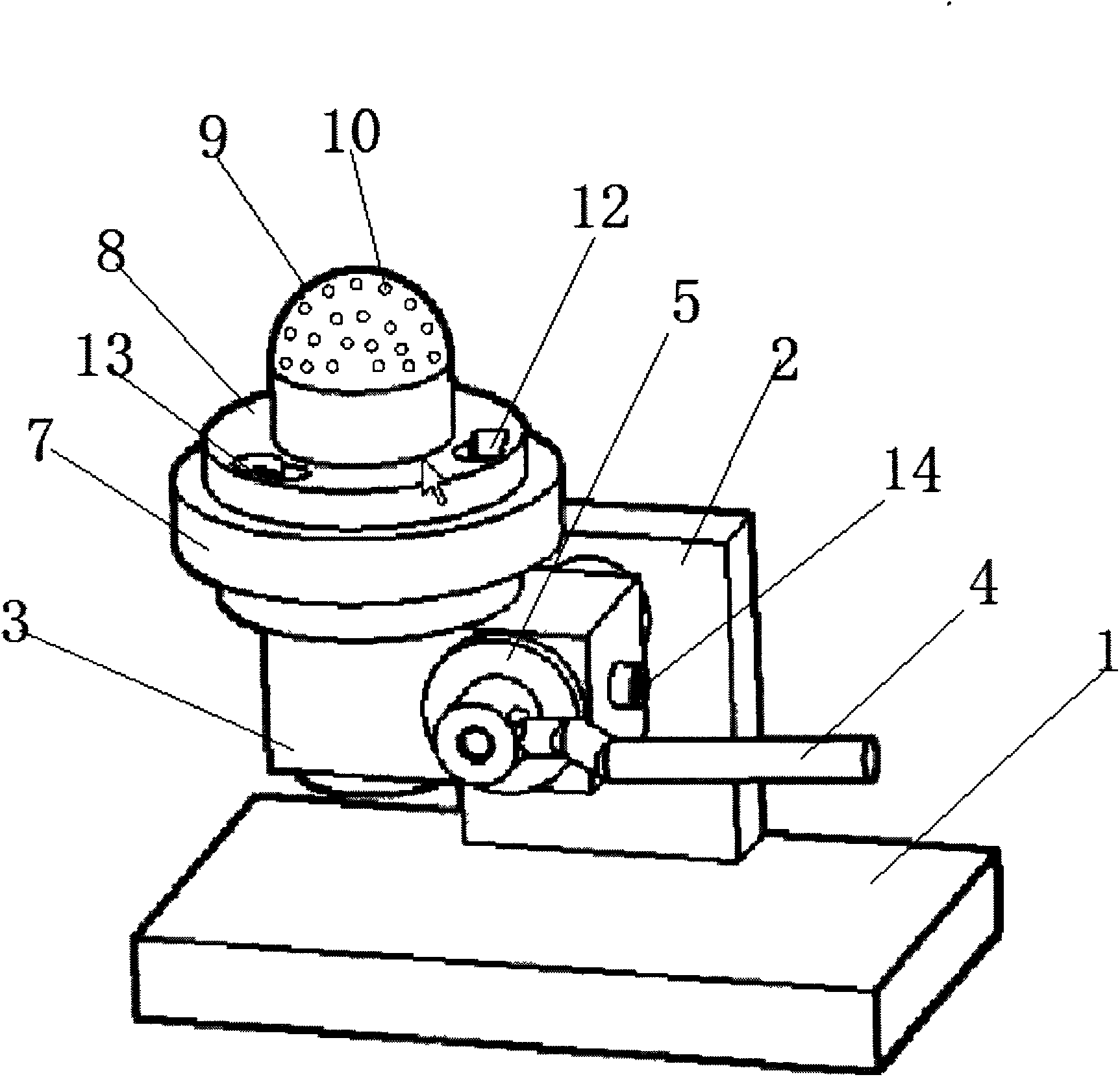

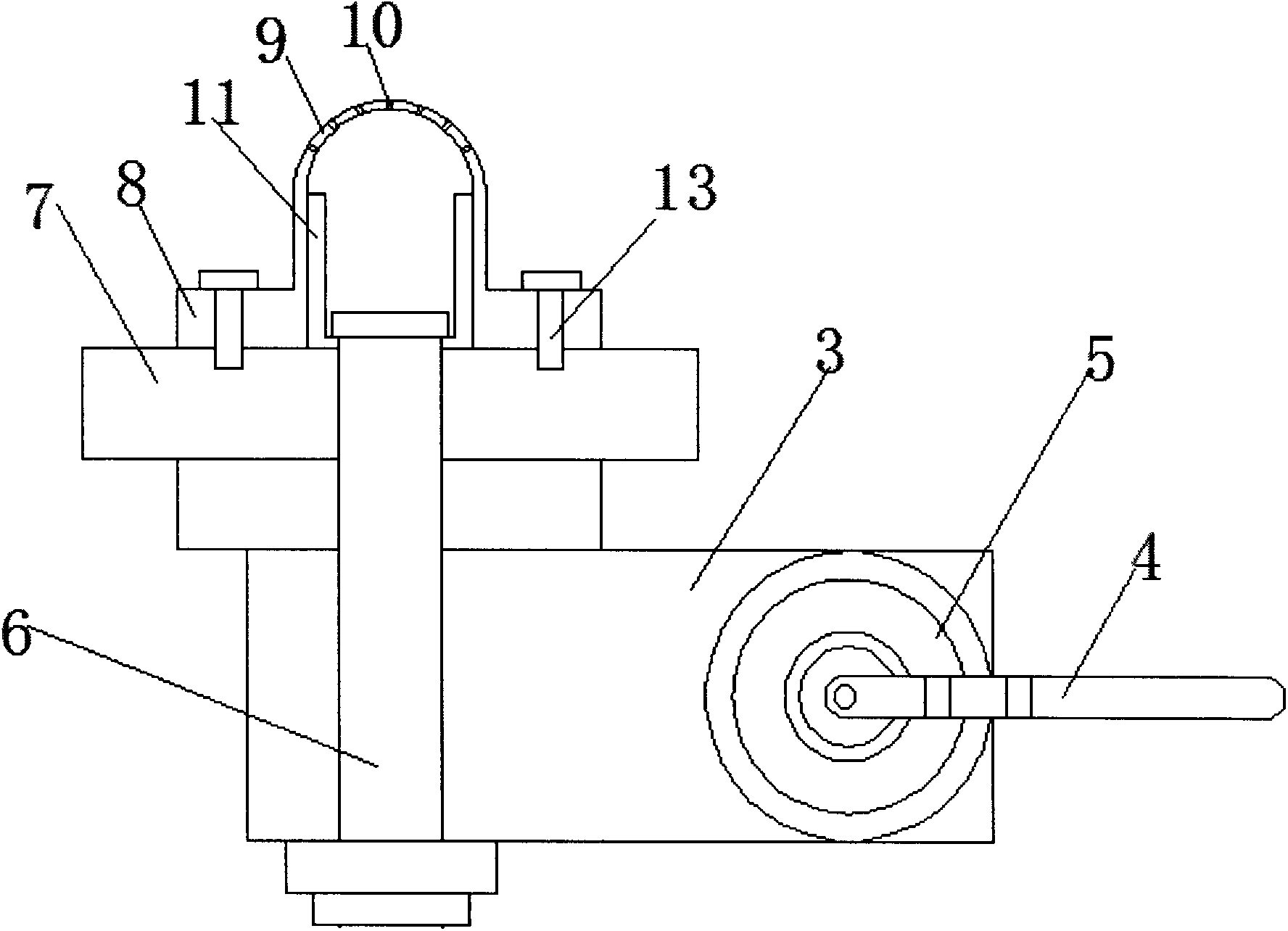

[0015] Such as figure 1 A kind of adjustable auger drilling form shown, it comprises base 1, side support plate 2 and the swivel seat 3 that is arranged on the side support plate 2, the drilling form assembly that is rotatably connected on the turn seat 3, the swivel seat 3 The rotating shaft is threadedly matched with the joint of the locking handle 4, and a pressing plate 5 is arranged between the joint and the swivel seat 3. The described drilling template assembly includes a rotating shaft 6, a rotating disk 7 and a detachable drilling die, and the rotating shaft 6 and the rotating shaft The seat 3 is movably connected, and the rotating disk 7 is fixedly connected with the rotating shaft 6. The drilling mold includes a hemispherical mold 9 and a connecting disk 8, and the connecting disk 8 is connected with the rotating disk 7. The hemispherical mold 9 is provided with guides for guiding when a plurality of workpieces are drilled. Holes 10, bosses 11 for pressing workpiece...

Embodiment 2

[0017] The turntable 7 described in the above scheme is connected with the rotating shaft 6 by bolts.

Embodiment 3

[0019] The connecting plate 8 described in Embodiment 1 is provided with a curved groove 12 , and the aperture diameter of the curved groove 12 gradually decreases along the rotation direction of the turntable 7 , and a locking screw 13 is arranged at a corresponding position on the turntable 7 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap