Ecological diatom coating and preparation method thereof

A technology of diatom coating and manufacturing method, applied in the direction of coating and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

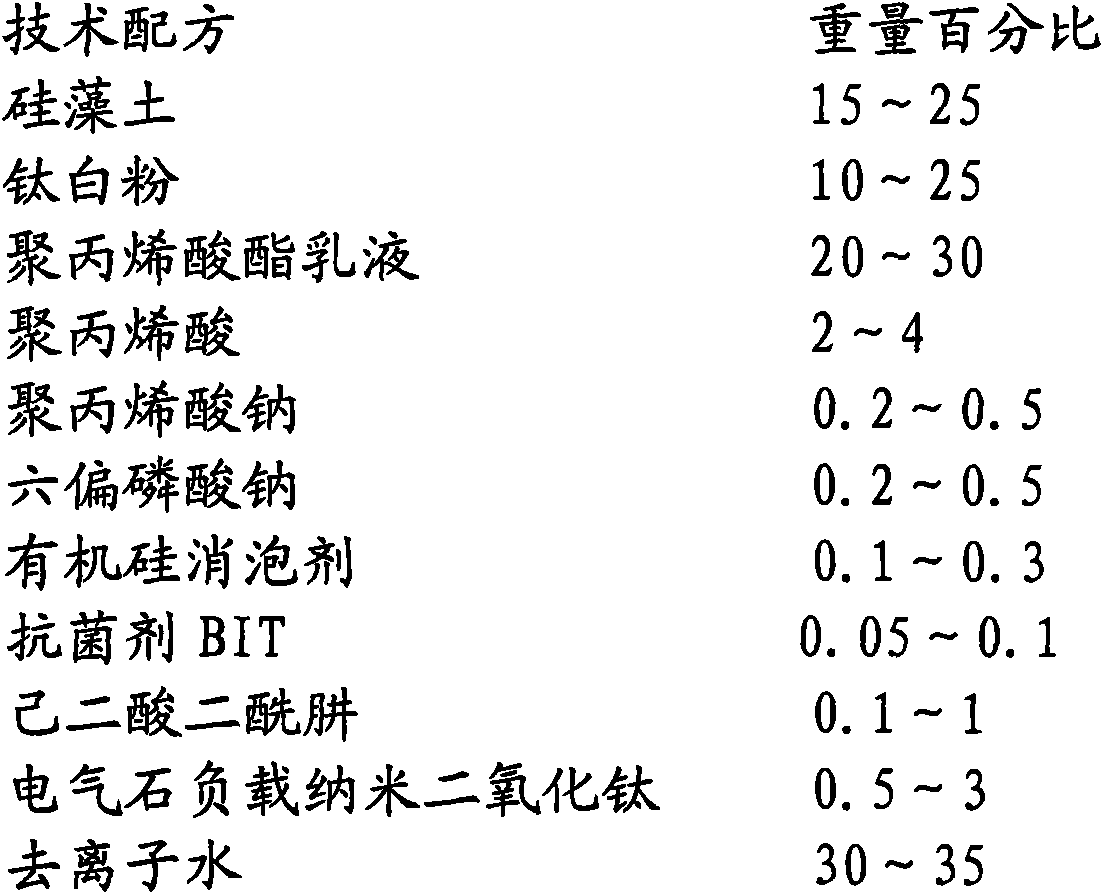

Method used

Image

Examples

Embodiment 1

[0017] Take 20kg of diatomite, 10kg of titanium dioxide, 25kg of polyacrylate emulsion, 4kg of polyacrylic acid thickener, 0.5kg of sodium polyacrylate dispersant, 0.5kg of sodium hexametaphosphate, 0.3kg of organic silicon defoamer, and antibacterial agent BIT0. 1kg, 0.5kg of adipic acid dihydrazide, 2.8kg of tourmaline-loaded nano-titanium dioxide, and 37kg of deionized water.

[0018] The equipment used is a mixing tank, in which deionized water is first added in proportion, stirred at a high speed, and antibacterial agent BIT, sodium polyacrylate dispersant, sodium hexametaphosphate, adipic acid dihydrazide, tourmaline are added while stirring Loaded with nano-titanium dioxide, silicone defoamer, titanium dioxide, diatomaceous earth. The stirring time was 30 minutes. After the dispersion is uniform, stir at a low speed, and add the polyacrylate emulsion while stirring, and the stirring time is 15 minutes. After dispersing evenly, stir at a high speed, and add polyacrylic...

Embodiment 2

[0020] Take 100kg of diatomite, 50kg of titanium dioxide, 120kg of polyacrylate emulsion, 15kg of polyacrylic acid thickener, 2.5kg of sodium polyacrylate dispersant, 1kg of sodium hexametaphosphate, 1.5kg of silicone defoamer, and 0.5kg of antibacterial agent BIT , adipic acid dihydrazide 2kg, tourmaline loaded nano-titanium dioxide 14kg, deionized water 150kg.

[0021] The equipment used is a mixing tank, in which deionized water is first added in proportion, stirred at a high speed, and antibacterial agent BIT, sodium polyacrylate dispersant, sodium hexametaphosphate, adipic acid dihydrazide, tourmaline are added while stirring Loaded with nano-titanium dioxide, silicone defoamer, titanium dioxide, diatomaceous earth. The stirring time was 30 minutes. After the dispersion is uniform, stir at a low speed, and add the polyacrylate emulsion while stirring, and the stirring time is 15 minutes. After dispersing evenly, stir at a high speed, and add polyacrylic acid thickener w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com