car cover

A tile cover and automobile technology, which is applied to cylinder heads, cylinders, engine components, etc., can solve problems such as shrinkage cavities, risers that cannot be fed, narrow process adaptability, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

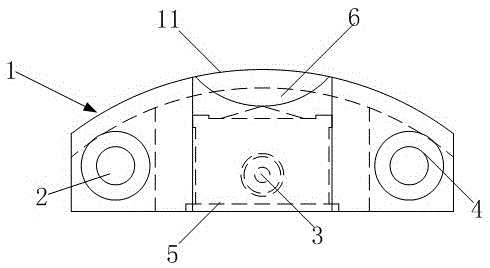

[0013] Such as figure 1 As shown, the automobile tile cover of the present invention includes a housing 1, a first bolt hole 2, a fixing hole 3, a second bolt hole 4, and a positioning pin hole 5, and the first bolt hole 2 and the second bolt hole 4 are respectively located in the housing 1. The positioning pin hole 5 is located between the first bolt hole 2 and the second bolt hole 4 on both sides, and the fixing hole 3 is located in the positioning pin hole 5 .

[0014] The diameter of the first bolt hole 2 is the same as that of the second bolt hole 4 , and the diameters of the first bolt hole 2 and the second bolt hole 4 are larger than the diameter of the positioning pin hole 5 .

[0015] The top surface of the housing 1 is arc-shaped, and the other three surfaces are straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com