Optical fiber F-P (Fabry-Perot) cavity pressure sensor with temperature self compensation

A pressure sensor, F-P technology, which is applied in the direction of force measurement by measuring the change of optical properties of the material when it is stressed, can solve the problems of reducing the pressure measurement accuracy of the optical fiber F-P cavity pressure sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

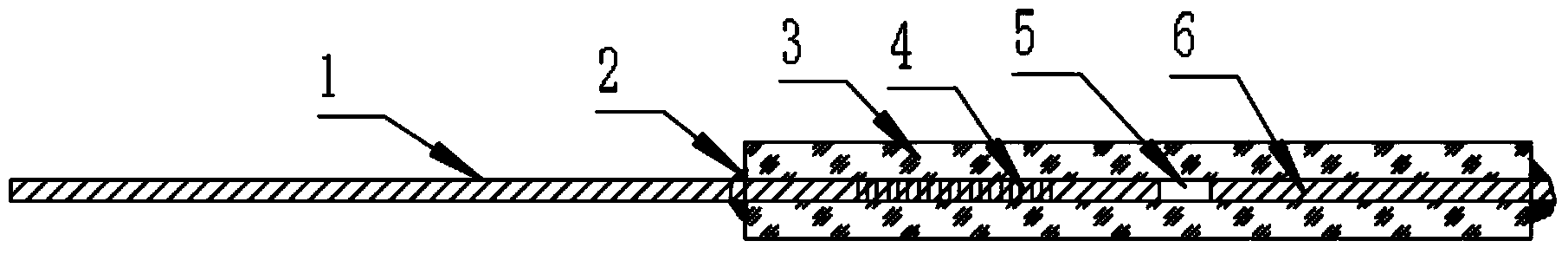

[0024] Such as figure 1 As shown, the fiber optic F-P cavity pressure sensor with temperature self-compensation, the sensing head of the sensor includes optical fiber A1, glass tube 3 and optical fiber B2;

[0025] A part of the optical fiber A1 is inserted into the glass tube 3, and the other part of the optical fiber A1 is located outside the glass tube 3, and is used as a conducting fiber to connect with peripheral demodulation equipment; welding;

[0026] The part of the optical fiber A1 inserted into the glass tube 3 is engraved with a grating 4;

[0027] The optical fiber B2 is completely inserted into the glass tube 3. In the glass tube 3, an F-P cavity is formed between the end faces of the optical fiber A1 and the optical fiber B2; the end face of the optical fiber A1 in the glass tube 3 is a reflective end face of the F-P cavity; The end face in the tube 3 is another reflective end face of the F-P cavity;

[0028] The above-mentioned sensor belongs to the lateral ...

Embodiment 2

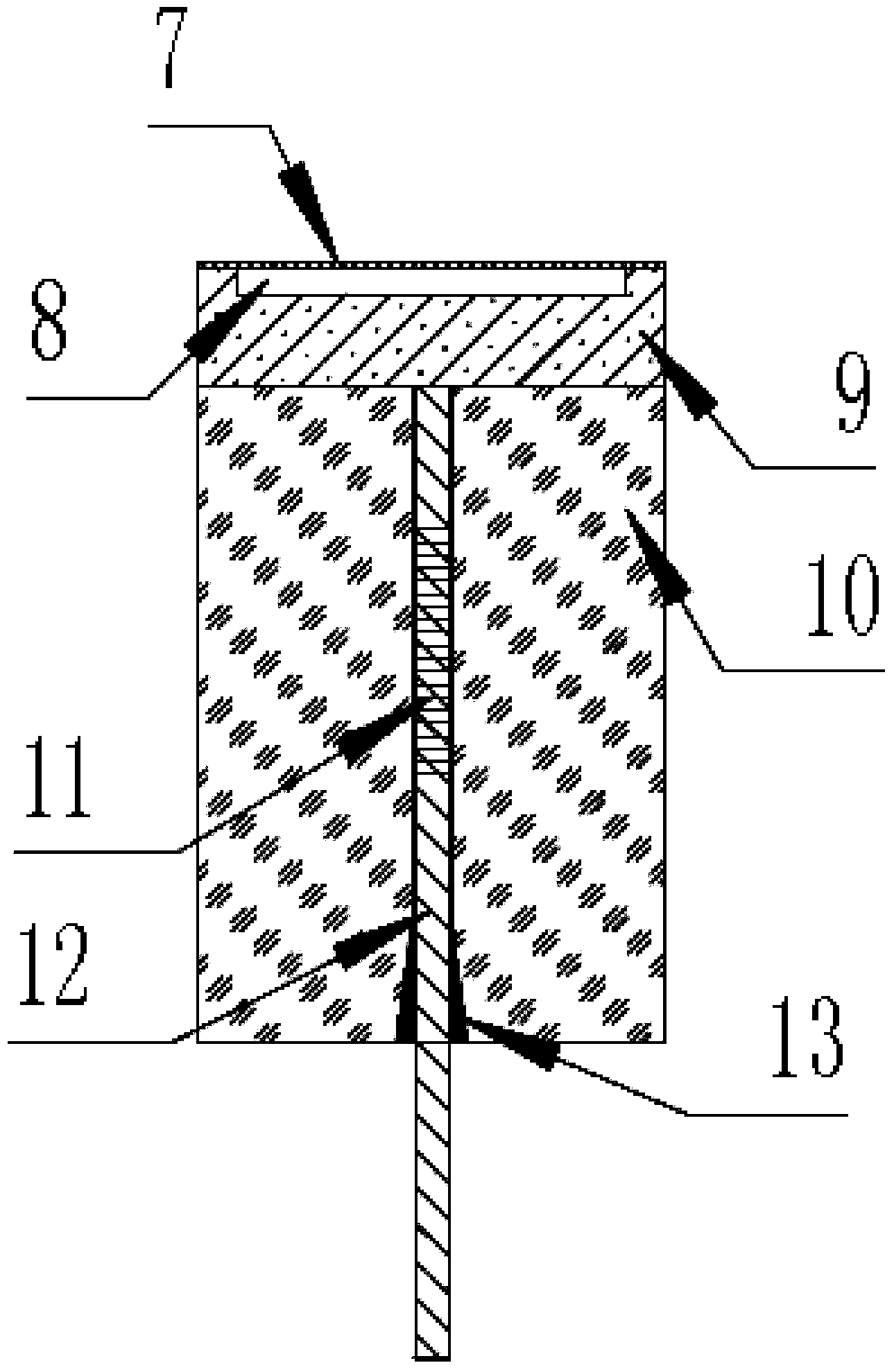

[0033] Such as figure 2 As shown, an optical fiber F-P cavity pressure sensor with temperature self-compensation, the sensing head of the sensor includes a diaphragm 7, a cavity bottom 9, a light guiding fiber 12 and a collimator 10;

[0034] There is a groove on the top of the cavity bottom 9, the diaphragm 7 and the cavity bottom 9 are bonded together by anodic bonding, and the F-P vacuum chamber 8 is formed between the diaphragm 7 and the groove;

[0035] The bottom end of the collimator tube 10 and the cavity bottom 9 is glued or welded by carbon dioxide laser;

[0036] The bottom end of the collimator 10 is drilled with a horn hole 13, the inner wall of the horn hole 13 is bonded with a layer of adhesive, a part of the light guiding fiber 12 is inserted into the collimating tube 10 through the horn hole 13, and the top of the light guiding fiber 12 It is flush with the lower surface of the cavity bottom 9; the part of the light guide fiber 12 inserted into the collimato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com