Optical depolarizer

A depolarizer and optical technology, applied in the direction of coupling of optical waveguides, can solve the problems of unsuitable depolarizer, complicated operation process, inconvenient maintenance and installation, etc., and achieves a simple structure, guaranteed depolarization effect, and low optical loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

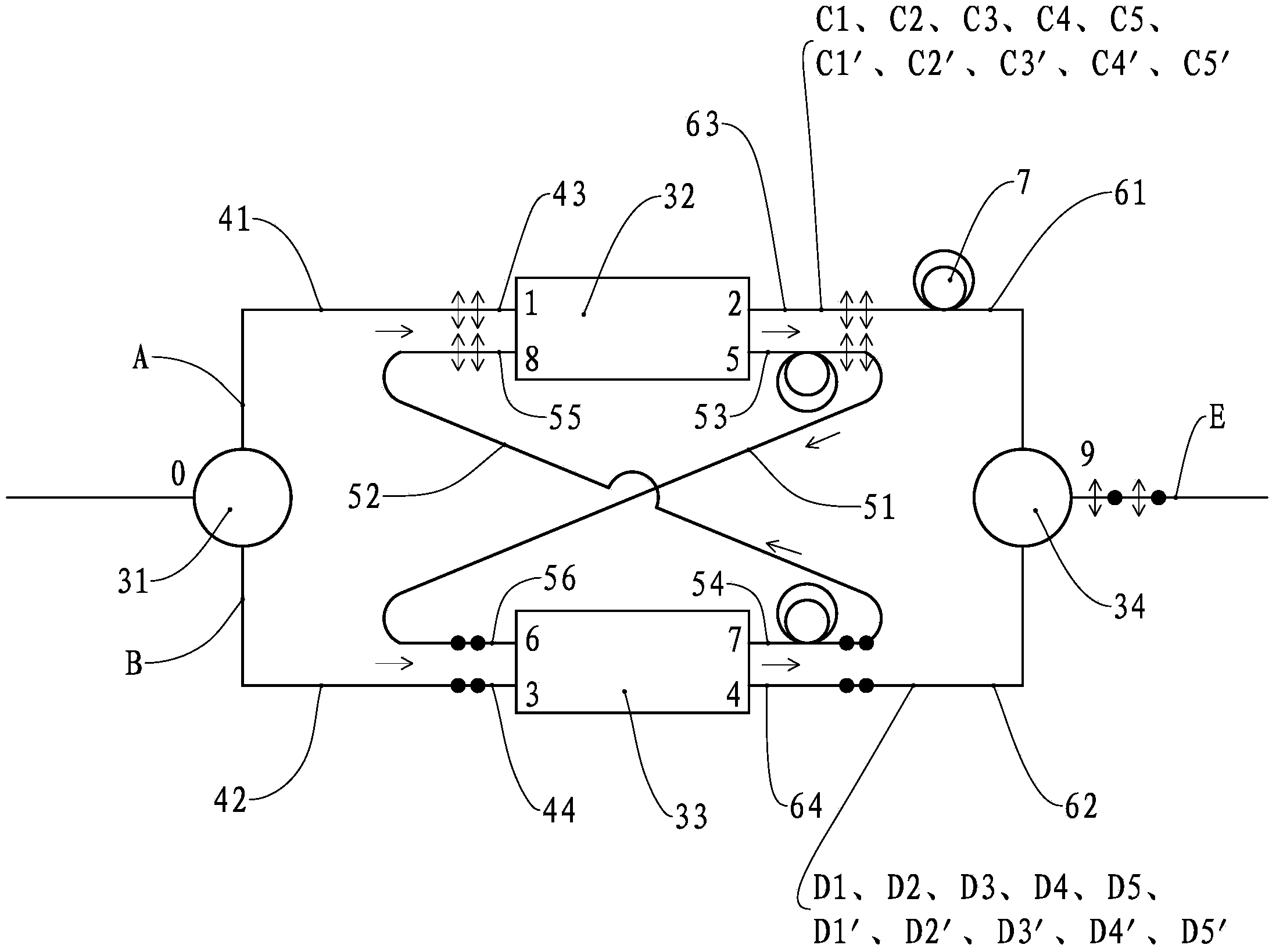

[0032] refer to image 3 , image 3 It is a structural diagram of the optical depolarizer of the present invention. The depolarizer includes a polarization beam splitter 31, a polarization maintaining coupler 32, a polarization maintaining coupler 33, and a polarization beam combiner 34, wherein the polarization maintaining coupler 32 is a 2×2 polarization maintaining coupler with a splitting ratio of 1:2 , the polarization maintaining coupler 32 includes an input port 1, an input port 8, an output port 2 and an output port 5, the polarization maintaining coupler 33 is a 2×2 polarization maintaining coupler with a splitting ratio of 1:2, and the polarization maintaining coupler 33 Including input port 3, input port 6, output port 4 and output port 7.

[0033] One output end of the polarization beam splitter 31 is connected to the input port 4 through an input polarization maintaining fiber 41 , and the other output end of the polarization beam splitter 31 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com