Electronic circuit module and manufacturing method thereof

A technology of electronic circuit and production method, which is applied in the direction of printed circuit manufacturing, circuit, printed circuit, etc., and can solve problems such as difficult to obtain shielding effect, burr at cutting position, interface peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

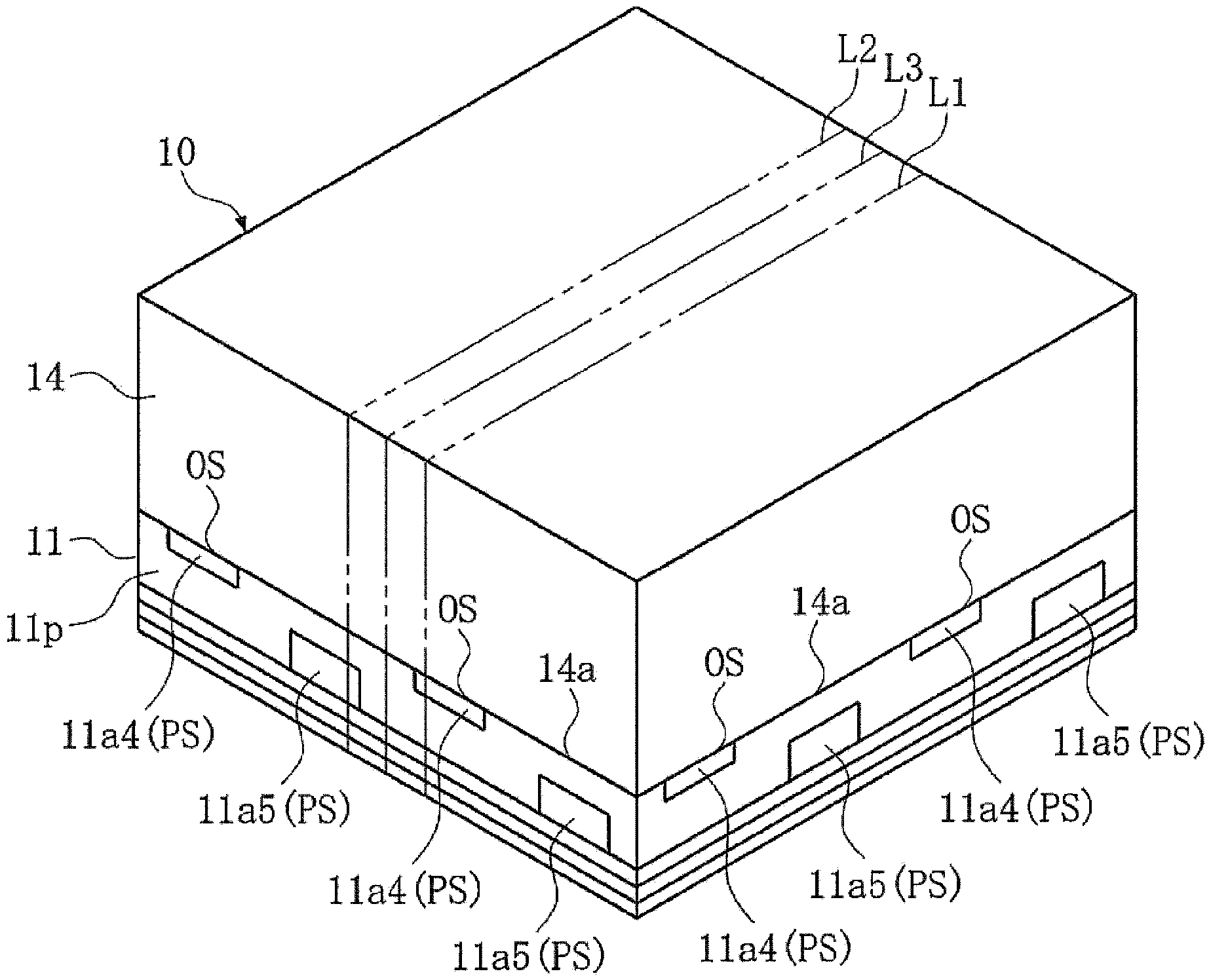

[0032] [Structure of electronic circuit module]

[0033] Figure 1 ~ Figure 5 The illustrated electronic circuit module 10 has: a component built-in substrate 11; a mounting component 12, which is mounted on the component built-in substrate 11; a package portion 13, which covers the mounting component 12; a shielding portion 14, which The electronic circuit is provided on the package part 13 and thus has a three-dimensional structure including the built-in component 11 b and the electronic circuit of the mounted component 12.

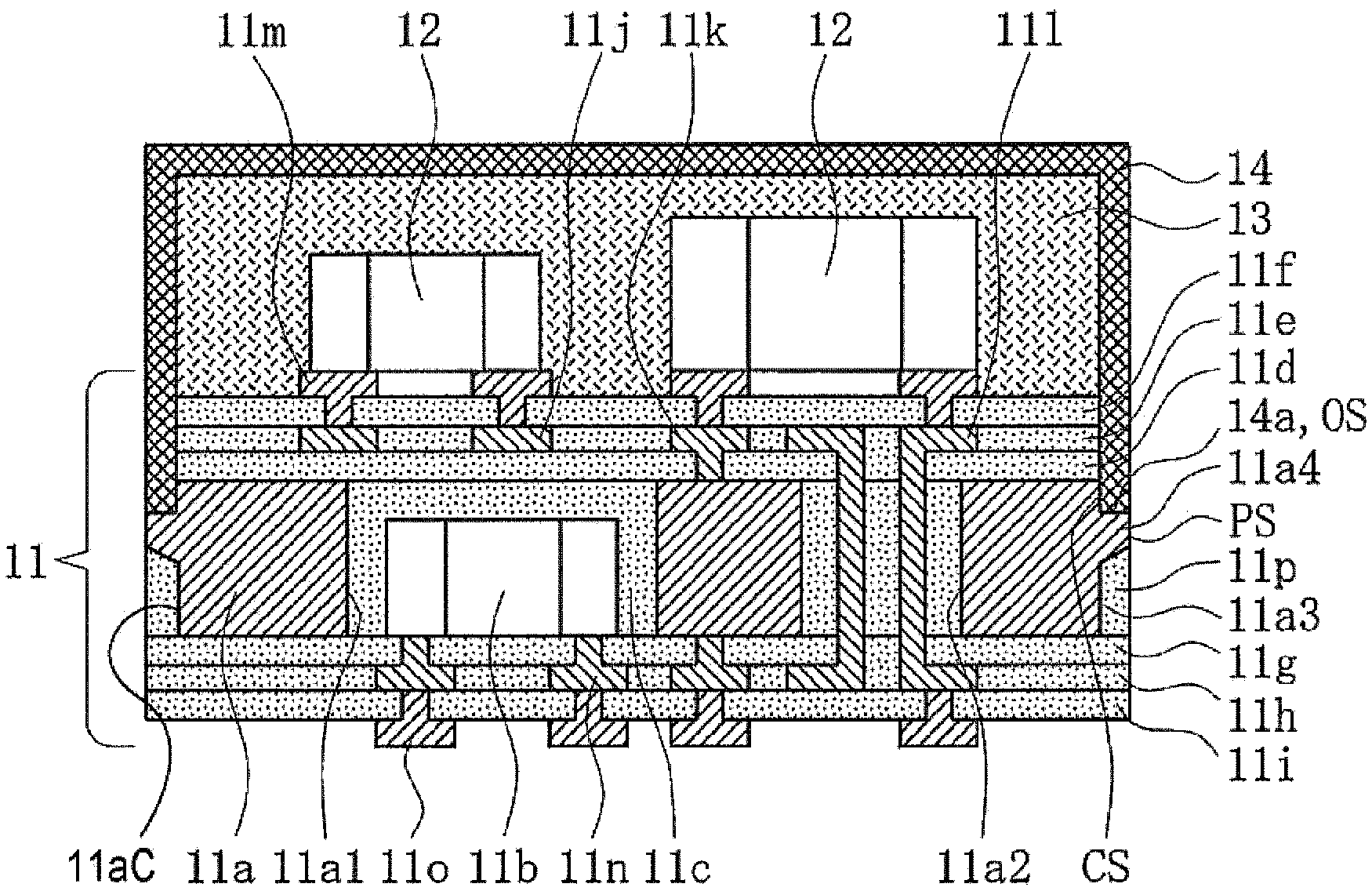

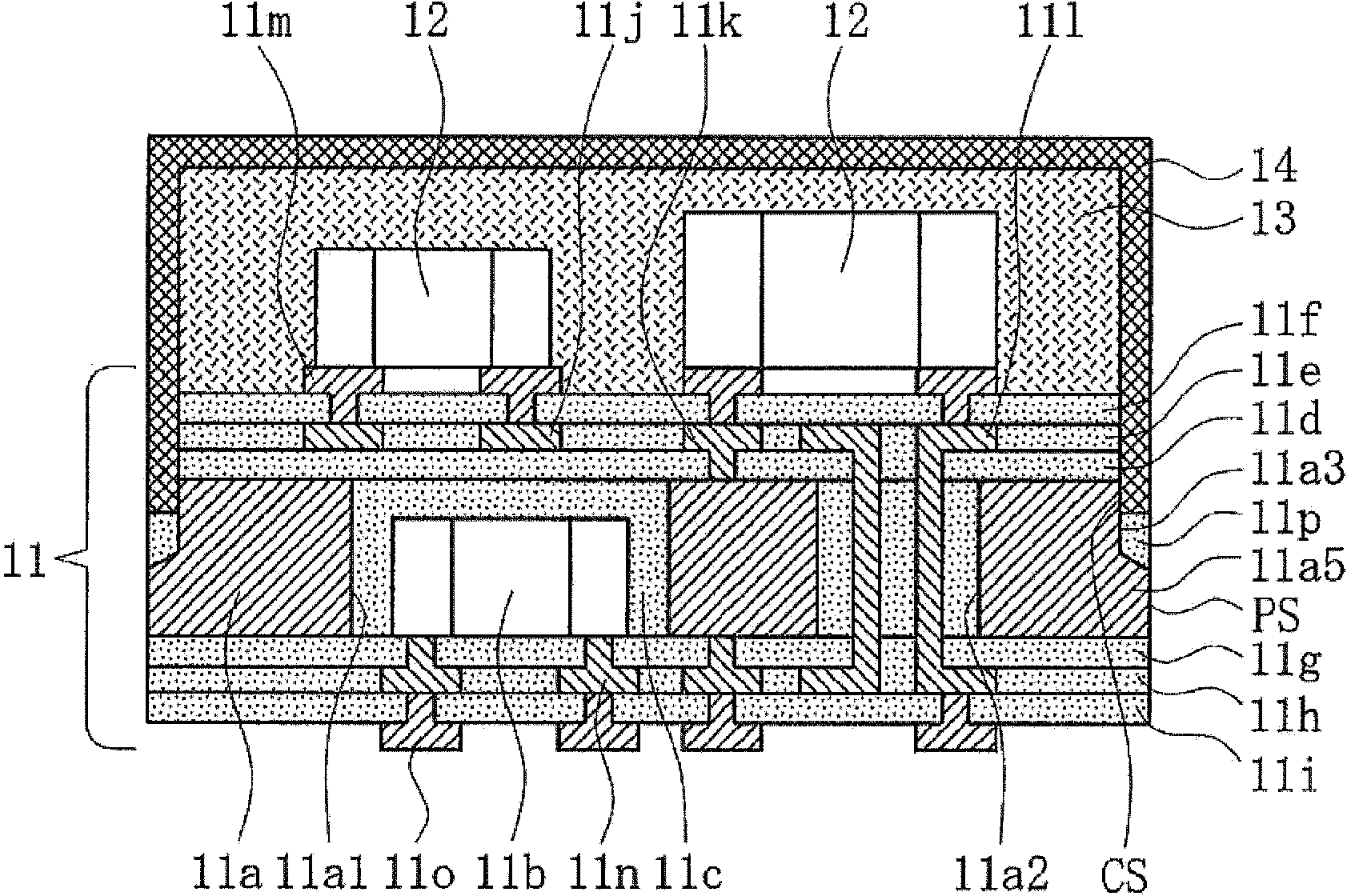

[0034] In addition, although Figure 2 ~ Figure 4 Position of the longitudinal section (refer to figure 1 Lines L1 to L3) are different, but for convenience of explanation, except Figure 2 ~ Figure 4 Except for the side surface portion of the base layer 11a described below, the other cross-sectional structures are the same.

[0035] Such as Figure 2 ~ Figure 4 As shown, the component built-in substrate 11 has: a base layer 11a; a built-in component 11b that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com