Process for delayed coking of whole crude oil

一种延迟焦化方法、延迟焦化的技术,应用在延迟焦化全馏分原油领域,能够解决基建成本运行成本增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] The coking method model commonly used in industry is improved to reflect the presence of light components and the corresponding yield based on the middle boiling temperature of the respective fractions. The model also includes experimental data on feed flow characteristics.

[0062] Table 1 lists Arabian heavy crude oil feed streams, their properties and composition, where CRR is the Conradson carbon residue value as a weight percentage of the starting material, and IBP and FBP are the initial and final boiling points, respectively.

[0063] Table 1

[0064] Performance

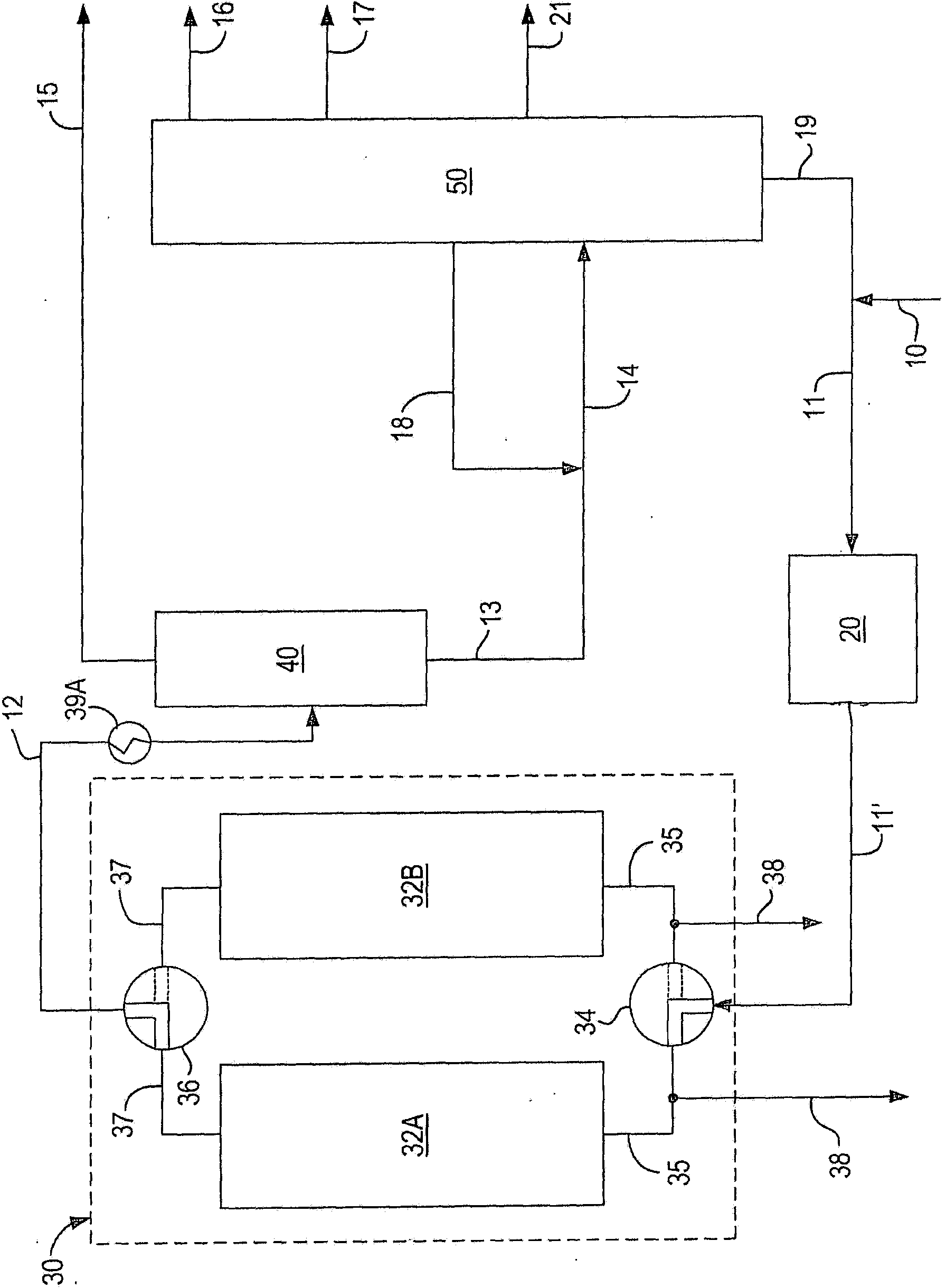

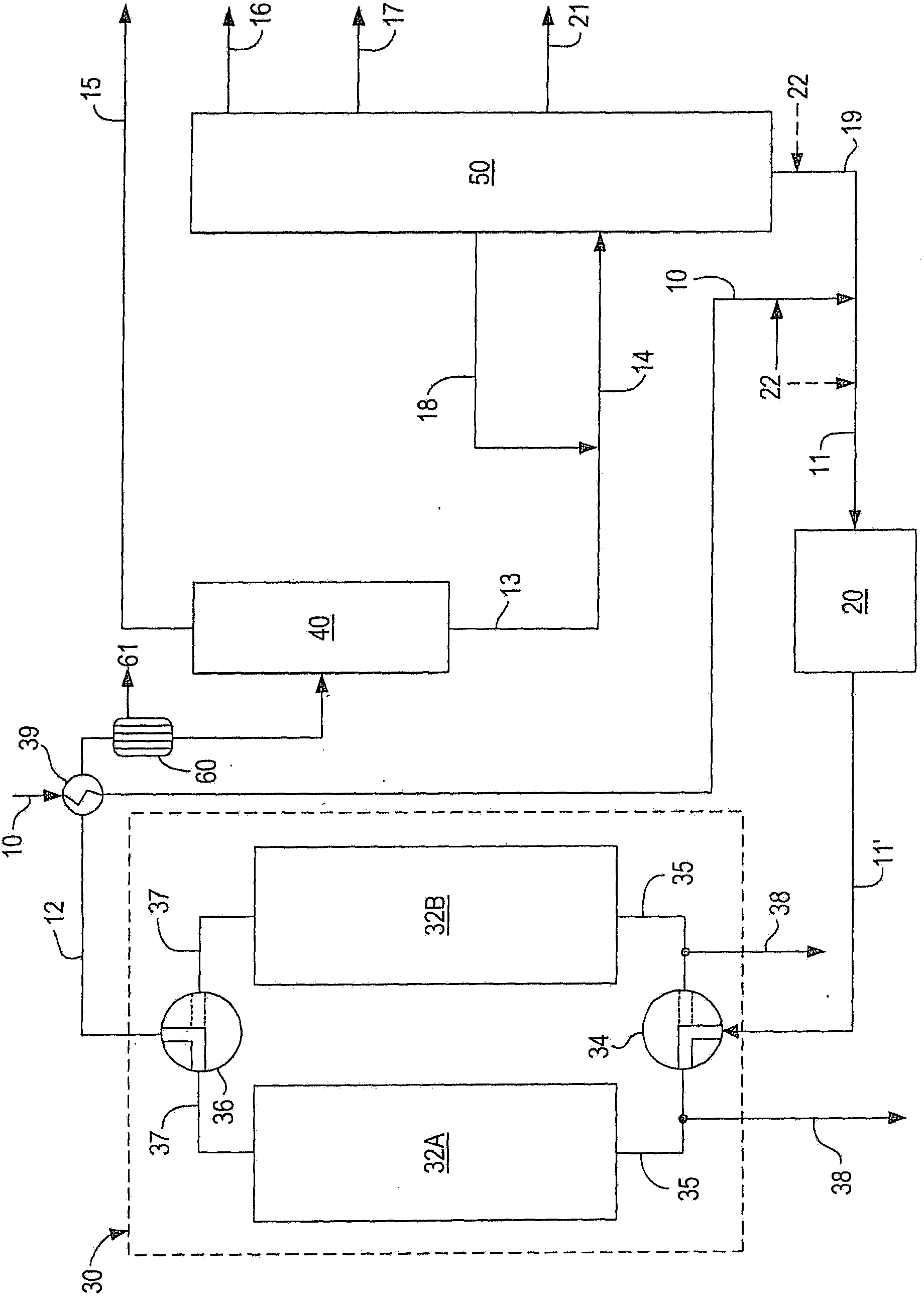

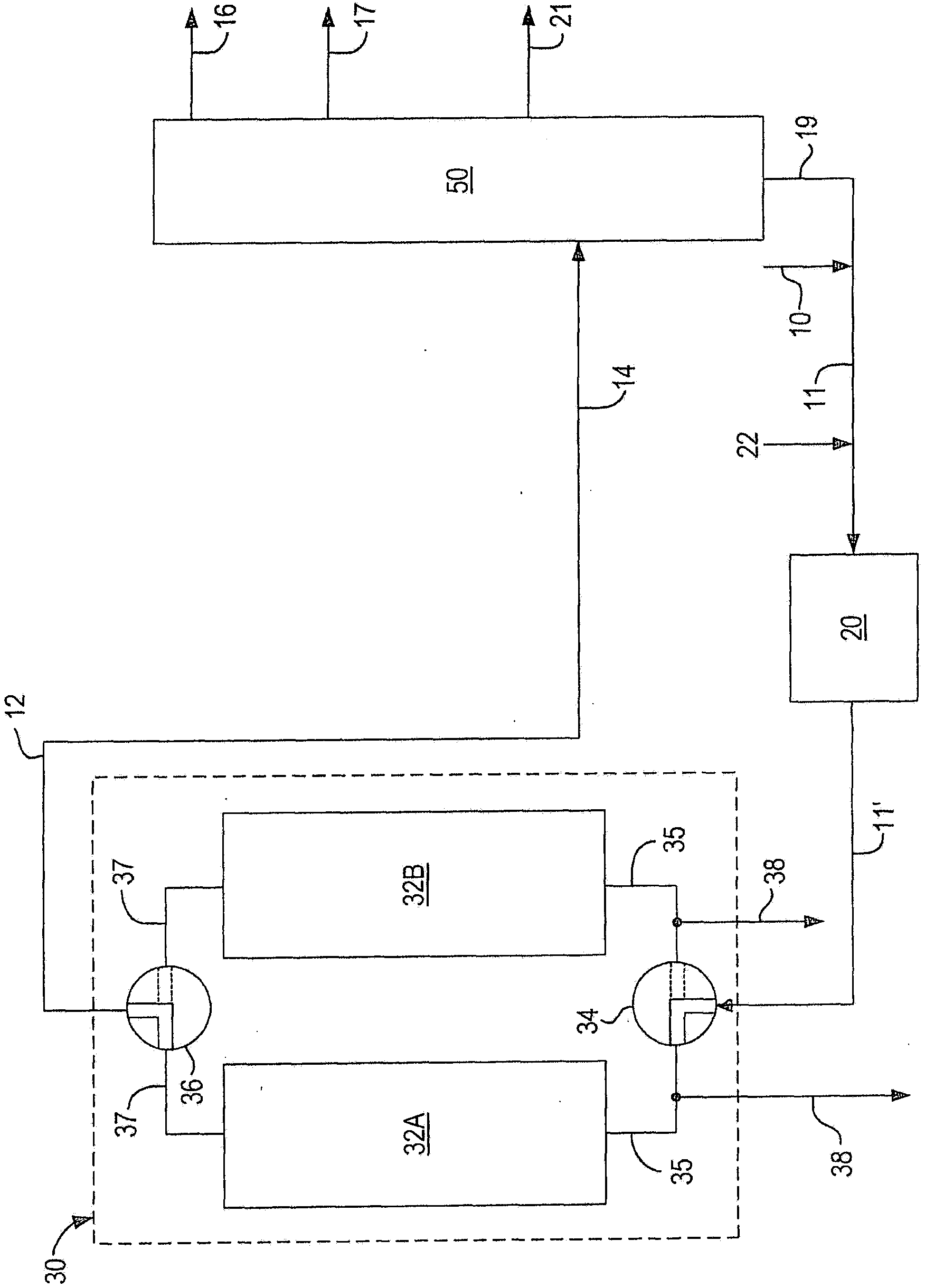

[0065] The feed stream was subjected to delayed coking at a temperature of 496°C at the furnace outlet and atmospheric pressure. The structure of the delayed coking unit is as follows image 3 Shown. The yield of the coking unit is summarized in Table 2.

[0066] Table 2

[0067] Yield

[0068] As shown in the data in Table 2, the full-distilled crude oil feed stream can be processed in the coking unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com