Pressure charging and relieving filtering system and method of high-temperature variable-pressure equipment for solid inlet and outlet materials

A technology of pressure transformation equipment, feeding and discharging materials, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of increased water consumption, complex black water treatment process, high investment, and achieve the effect of temperature relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

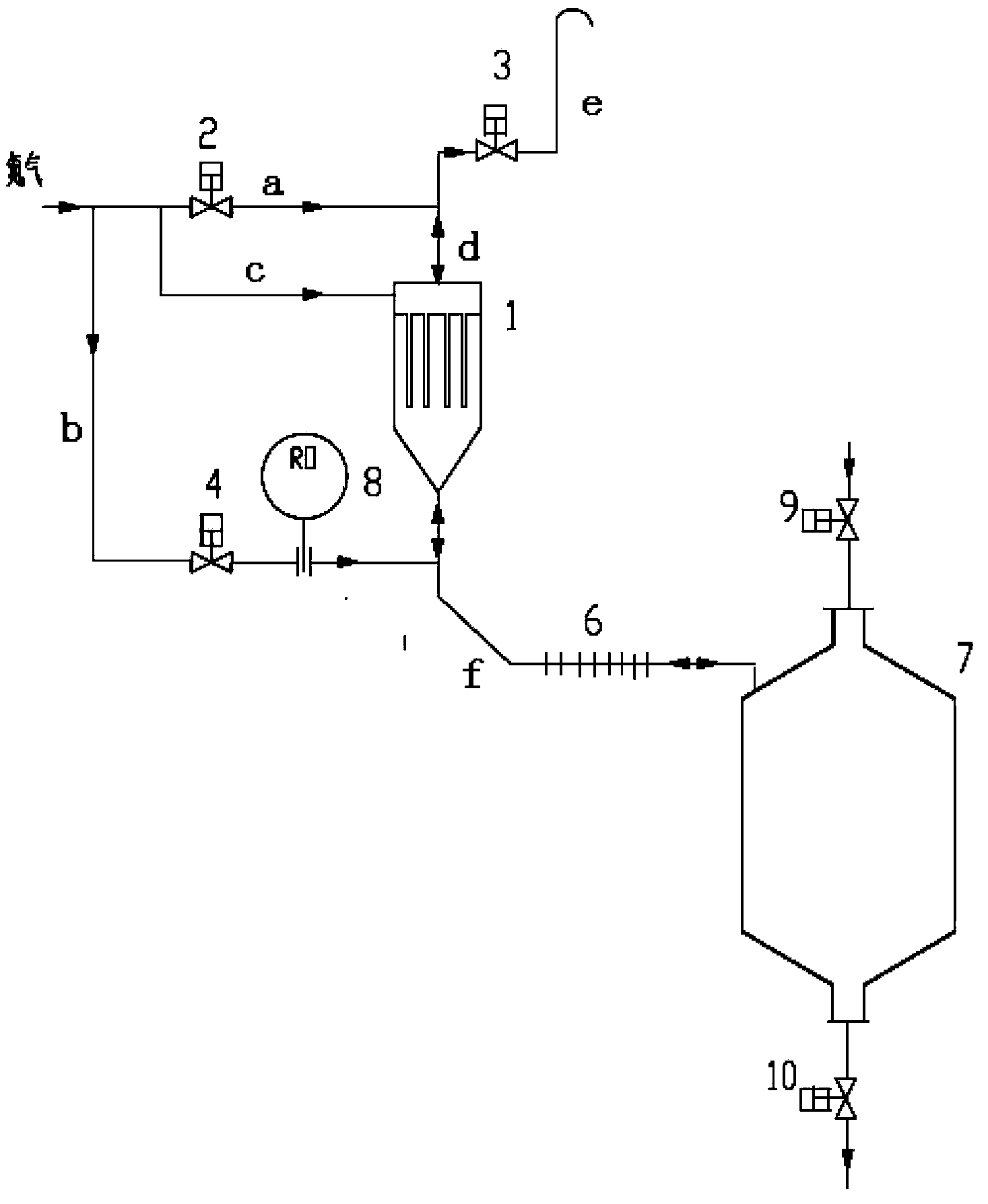

[0048] Such as figure 1 As shown in the figure, a high-temperature pressure-transformation equipment charging and discharging filter system for solid inlet and outlet.

[0049] Including: element filter and lock bucket, the inert gas inlet pipe is respectively connected to the top and bottom of the element filter; the pipeline b connected to the bottom of the element filter is provided with a programmable valve C and a flow-restricting orifice plate, connected to the top of the element filter The inert gas inlet pipe is divided into pipeline a and pipeline c, the pipeline a is equipped with a program-controlled valve A, the pipeline c is connected to the upper part of the element filter, the pipeline a is merged with the outlet pipeline d at the top of the filter element filter, and the combined A program-controlled valve B is set on the pipeline e, and the pipeline b merges with the pipeline f between the lock bucket and the filter element filter, and the pipeline f is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com