Dedusting system combining flue gas ash conveying and filtering

A technology for conveying ash and flue gas, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of high operating cost, severe wear and tear of conveying pipelines, and heavy maintenance workload, so as to reduce energy consumption and The effect of reducing operating costs, reducing maintenance workload, and saving steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

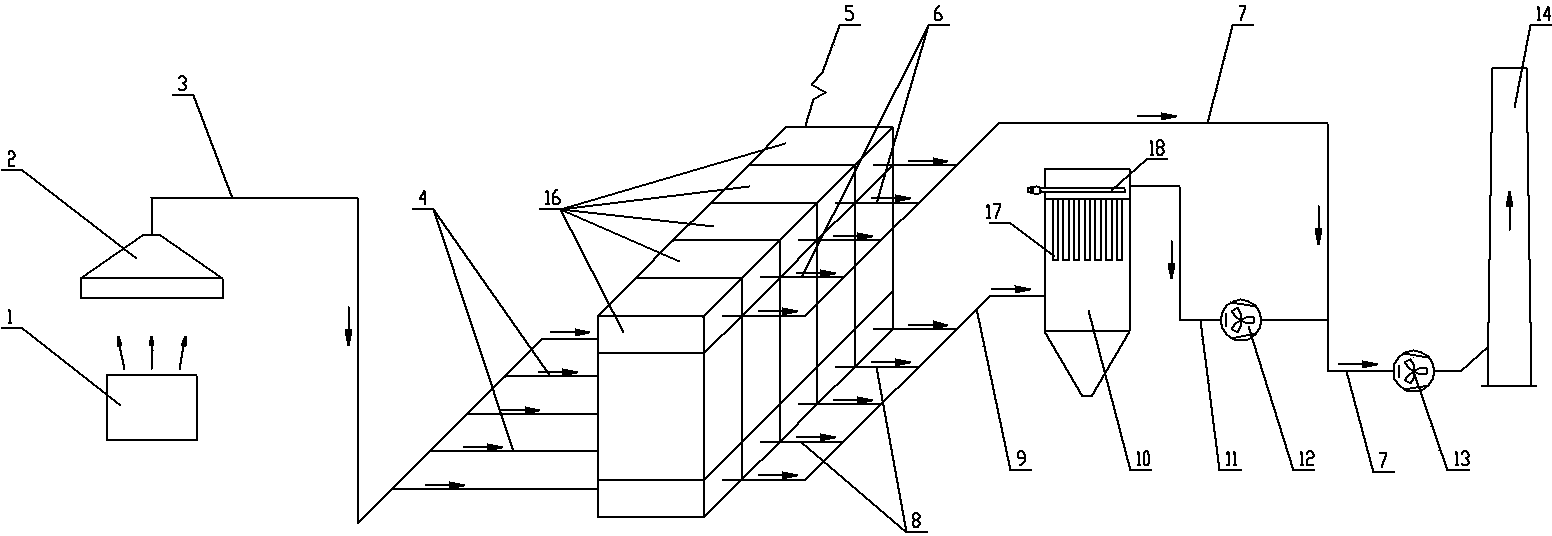

[0011] Specific embodiment one: see figure 1 , the end of the clean air main pipe 7 is directly connected to the bottom air inlet of the chimney 14, the clean air pipe 11 connects the middle part of the clean air main pipe 7, and the dust removal fan 13 is positioned at the rear of the end of the clean air pipe 11.

[0012] Its working principle is as follows: its workflow is as follows:

[0013] The flue gas or dust emitted by the dust source 1 is captured by the collection hood 2, and the collected flue gas or dust enters the flue gas main pipe 3, and then enters the corresponding chamber of the dust collector 5 through each flue gas branch pipe 4 for dust removal. The clean gas after dedusting in each chamber enters each clean gas branch pipe 6, then enters the clean gas main pipe 7, and finally is sent to the chimney 9 by the dust removal fan 8 through the clean gas main pipe 7 for discharge.

[0014] Dust removal in dust collector 5 is carried out room by room in sequenc...

specific Embodiment 2

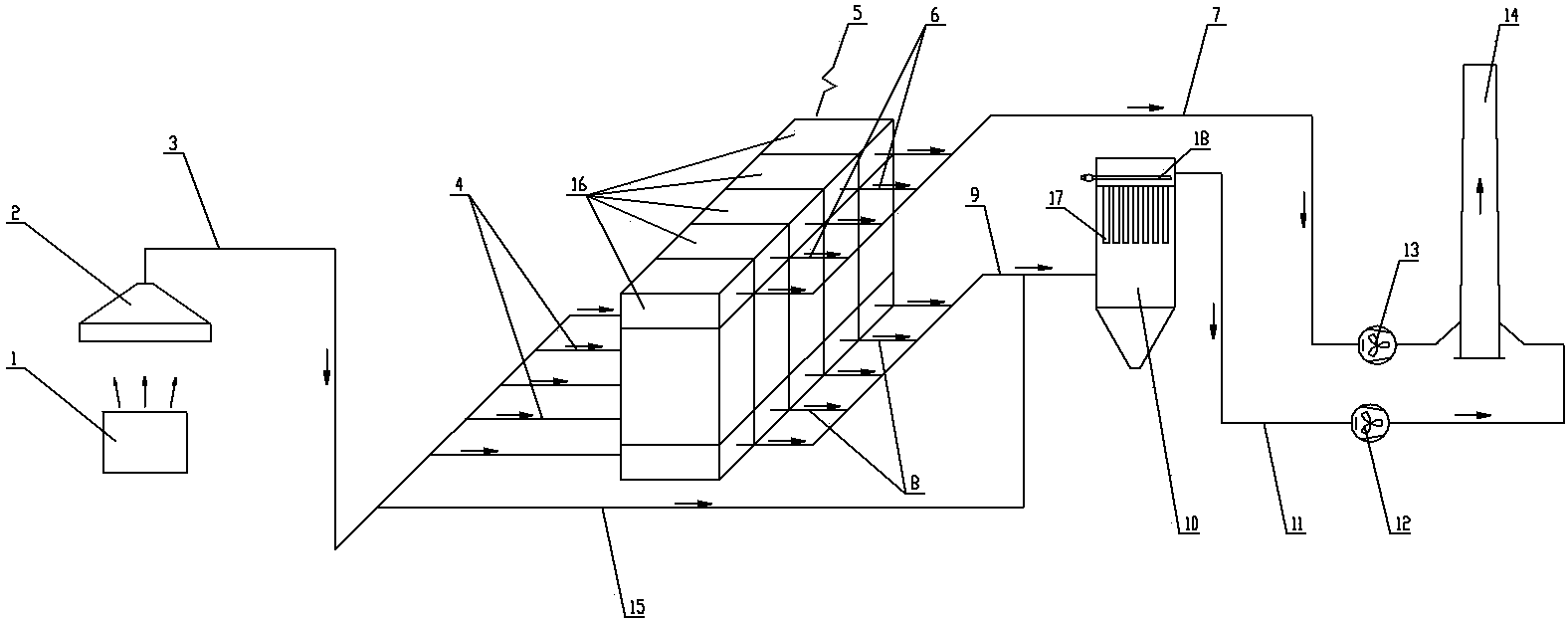

[0015] Specific embodiment two: see figure 2 , the clean gas main pipe 7 and the clean air pipe 11 are respectively connected to the bottom air inlet of the chimney 14, and the flue gas main pipe 3 is connected to the ash conveying main pipe 9 through the bypass pipe 15.

[0016] Its working principle is as follows: the flue gas or dust emitted by the dust source 1 is captured by the collecting cover 2, and the collected flue gas or dust enters the flue gas main pipe 3, and then most of the flue gas or dust passes through each flue gas branch pipe 4 Enter the chambers corresponding to the dust collector 5 for dust removal, and the clean gas after dedusting in each chamber enters each clean gas branch pipe 6, and then enters the clean gas main pipe 7, and finally is sent to the chimney 9 by the dust removal fan 8 through the clean gas main pipe 7. Emission; another part of flue gas or dust successively enters the ash storage bin 10 through the bypass pipe 15 and the ash convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com