Ball mill cooling method that can dedust the crushing workplace

A technology of ball mill and wet ball mill, which is applied in the direction of grain processing, etc., can solve the problems of consuming a lot of time, affecting the maintenance progress, and environmental pollution in surrounding places, so as to shorten the cooling time, improve the grinding efficiency, and improve the dust collection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

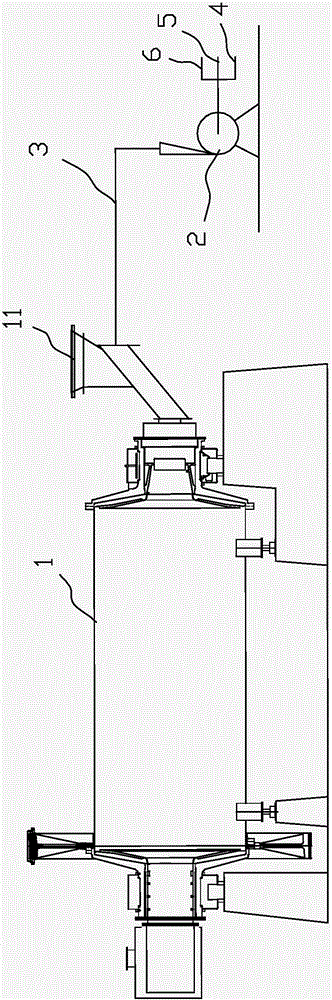

[0011] Depend on figure 1 As shown, the air outlet of the induced draft fan 2 passes through the air pipe 3, and communicates with the inner cavity of the cylinder body 1 by the feed inlet 11 of the ball mill. The air inlets of the air inlet pipes are set in the crushing workplace; each air inlet pipe is equipped with a valve.

[0012] In order to improve the dust suction effect, each air inlet pipe is equipped with a trumpet-shaped air inlet in the crushing workplace.

[0013] The number of air inlet pipes depends on the number of crushing work places, and each crushing work place can vacuum in batches or in turn.

[0014] It is also possible to arrange two to three air inlet pipes in one crushing operation site to improve the dust collection effect of the site.

[0015] Start the ball mill, when the temperature of the ball mill barrel 1 reaches 70-80°C, start the induced draft fan 2 to inhale the crushing work place through one or several air inlet pipes, and send the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com