Fluid distributor of liquid-solid fluidized bed separating and classifying equipment

A fluid distributor and fluid distribution technology, applied in the direction of solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of uneven distribution of water flow, affecting the continuous progress of the sorting process, affecting the sorting effect, etc., to achieve effective Conducive to collection and discharge, improved sorting effect, and smooth sorting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

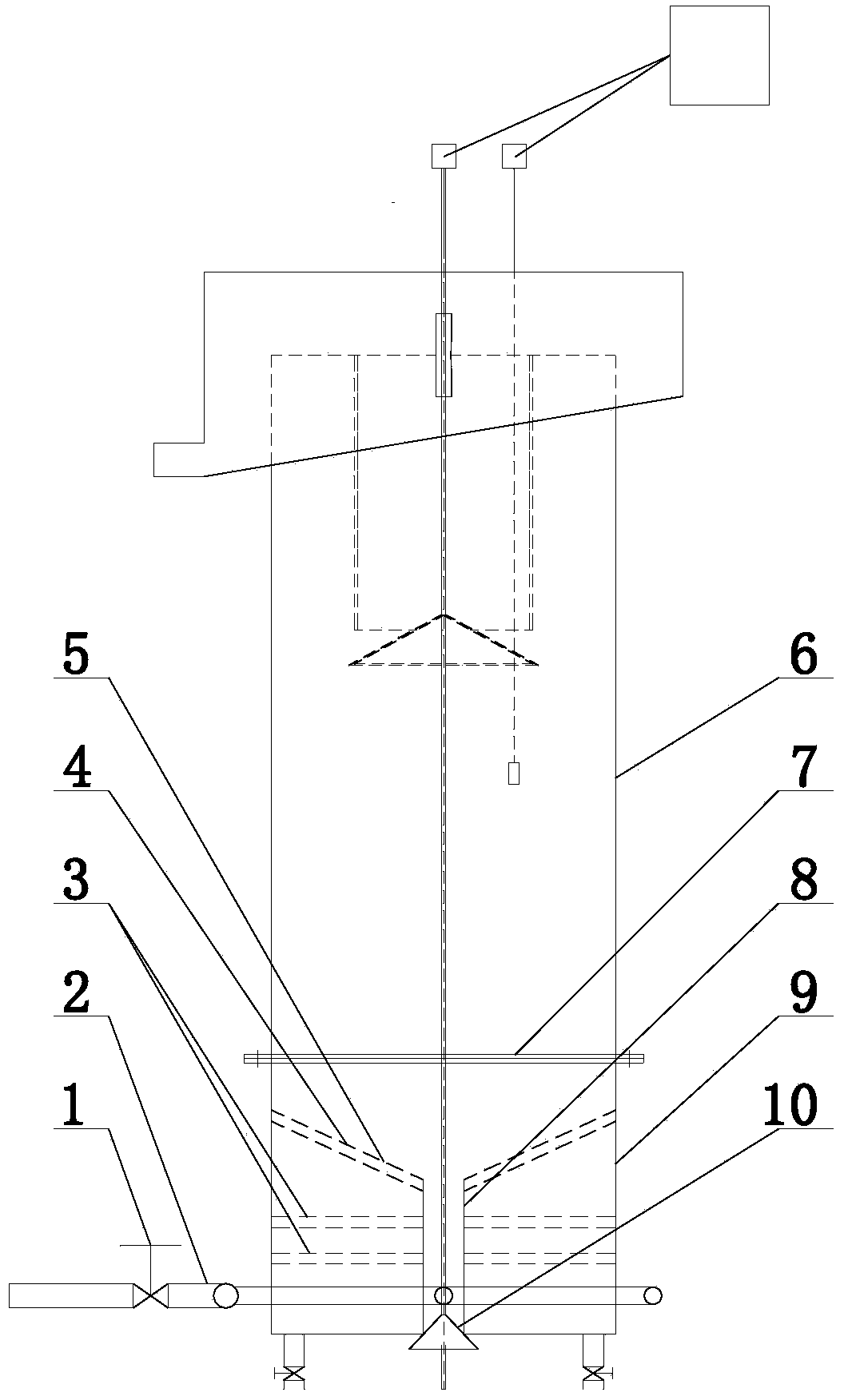

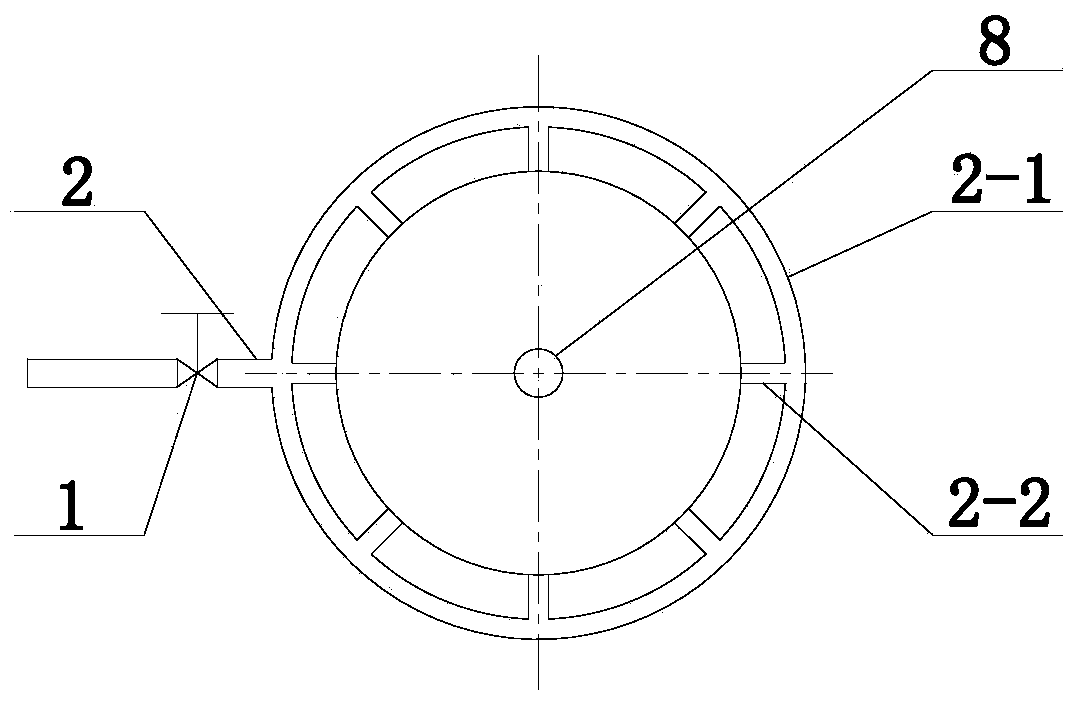

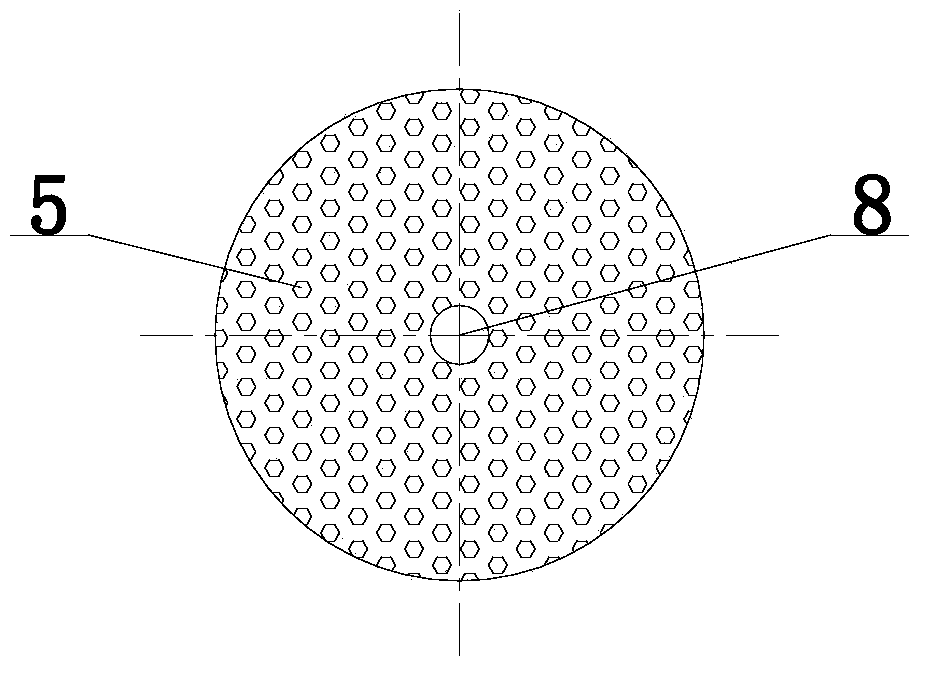

[0015] Such as figure 1 As shown, the fluid distributor of the liquid-solid fluidized bed separation and grading equipment of the present invention is mainly composed of a barrel, a valve 1 for controlling fluid flow and a fluid distribution pipe. The barrel body is connected as a whole by the upper barrel body 6 and the lower barrel body 9 through the flange 7, and the cross section of the barrel body is circular or rectangular. figure 1 The center is circular; the inside of the lower barrel 9 is higher than the level of the fluid distribution main pipe 2, and a multi-layer buffer fluid distribution plate 3 is arranged horizontally. The multi-layer buffer fluid distribution plate 3 is preferably 1-3 layers, figure 1 There are 2 layers in the middle. The upper part of the buffer fluid distribution plate 3 is provided with an inverted conical discharge flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com