Drum screen capable of automatically and intermittently cleaning screen cloth

A trommel screen and self-cleaning technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of easy clogging of the screen by materials, poor screening effect, and manual cleaning after shutdown, so as to reduce equipment maintenance costs and improve The effect of screening efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

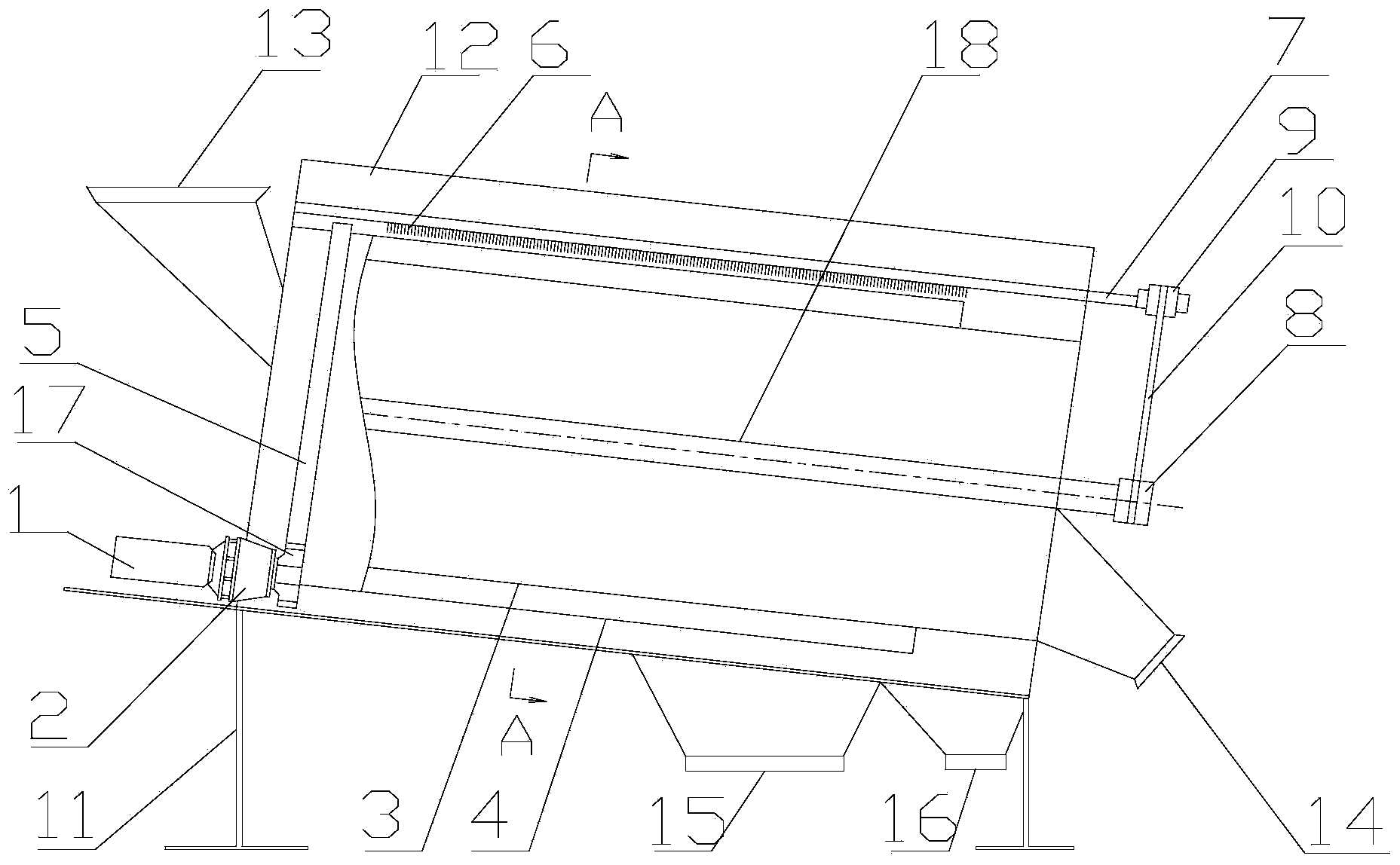

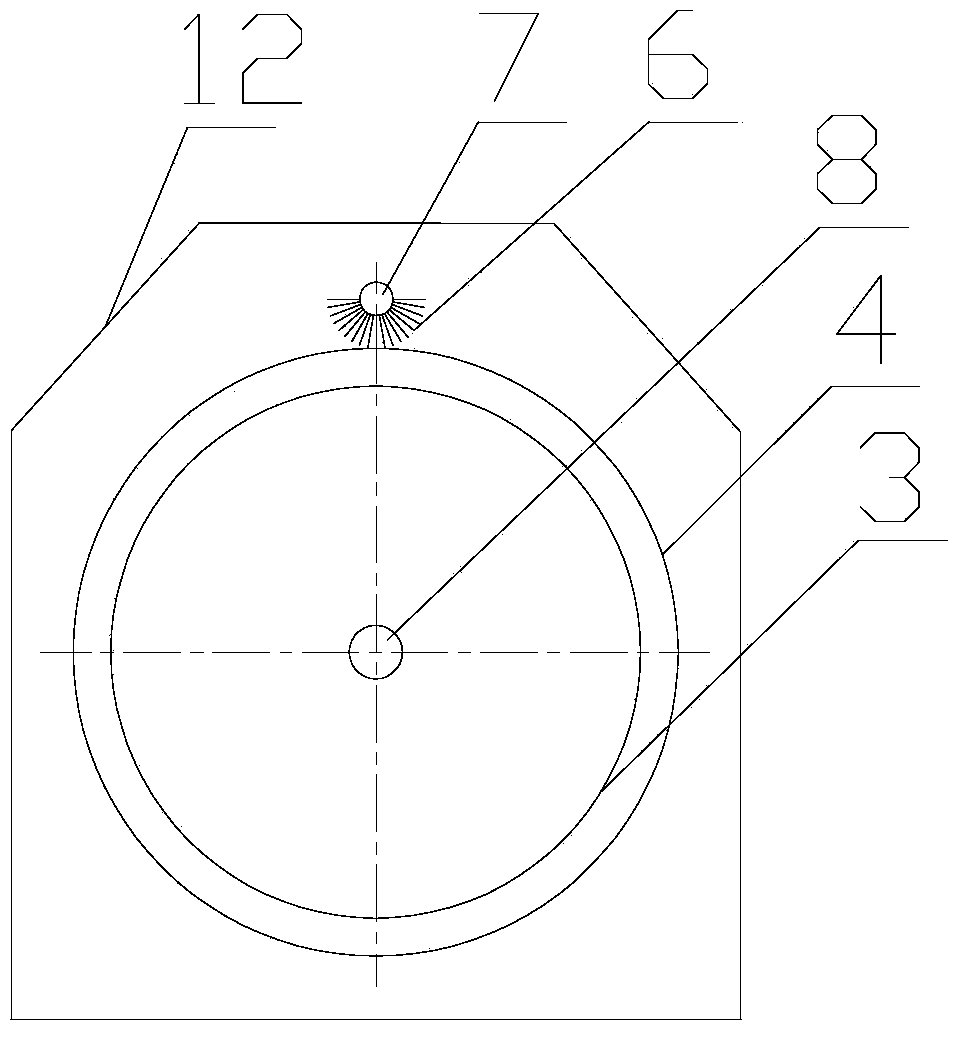

[0014] Such as figure 1 As shown, the intermittent automatic cleaning screen drum sieve of the present invention includes a motor 1, a reducer 2, a drum device, a cleaning device, a frame 11, a sealing cover 12, a feed port 13, a discharge port 14, a Material opening 15 and material outlet 16. The drum device is composed of inner drum screen 3, outer drum screen 4 and transmission gear 5. The cleaning device is made up of hair brush 6, eccentric shaft 7, large sprocket 8, small sprocket 9 and transmission chain 10. The drum device is installed obliquely on the frame 11. The motor 1 is connected with the drum device through the reducer 2 through the shaft coupling 17, and drives the drum device to rotate around the main shaft 18 of the drum screen. When the material enters the inner drum screen 3 from the feed port 13, due to the inclination and rotation of the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com