Threaded hole cleaner

A technology for cleaning devices and threaded holes, applied in cleaning methods and tools, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as mutual blow-by, affect engine performance, ablate cylinder pads, etc., and achieve high efficiency cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

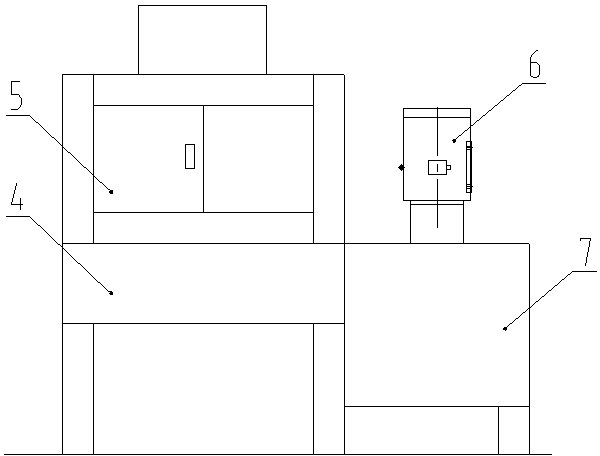

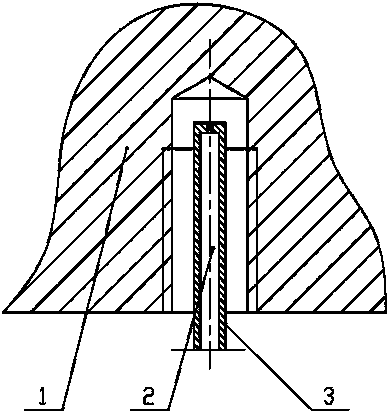

[0010] Such as figure 1 , 2 As shown, the screw hole cleaning device of the present invention includes a nozzle 3 , a sedimentation tank 4 , a cleaning tank 5 , a high-pressure water pump 6 and a water tank 7 .

[0011] The nozzle is connected to the outlet of the high-pressure water pump. The number of nozzles depends on the number of threaded holes on the workpiece to be cleaned. Put the workpiece 1 into the cleaning box, insert the nozzle into the threaded hole of the workpiece 1 to be cleaned, and start the high-pressure water pump. The high-pressure cleaning water 2 produced by the high-pressure water pump is injected into the bottom of the threaded hole through the nozzle, so that the iron filings and other sundries adsorbed in the threaded groove and deposited at the bottom of the threaded hole are taken out with the water flow.

[0012] Preferably, the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com