Casting method and device for closed type glass x-ray fixed oxygen-free copper anode target

An oxygen-free copper and x-ray technology, applied in the field of metal processing, can solve the problems of incompatibility, high energy consumption, long time consumption, etc., and achieve the effect of reducing production cost, wide application range, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

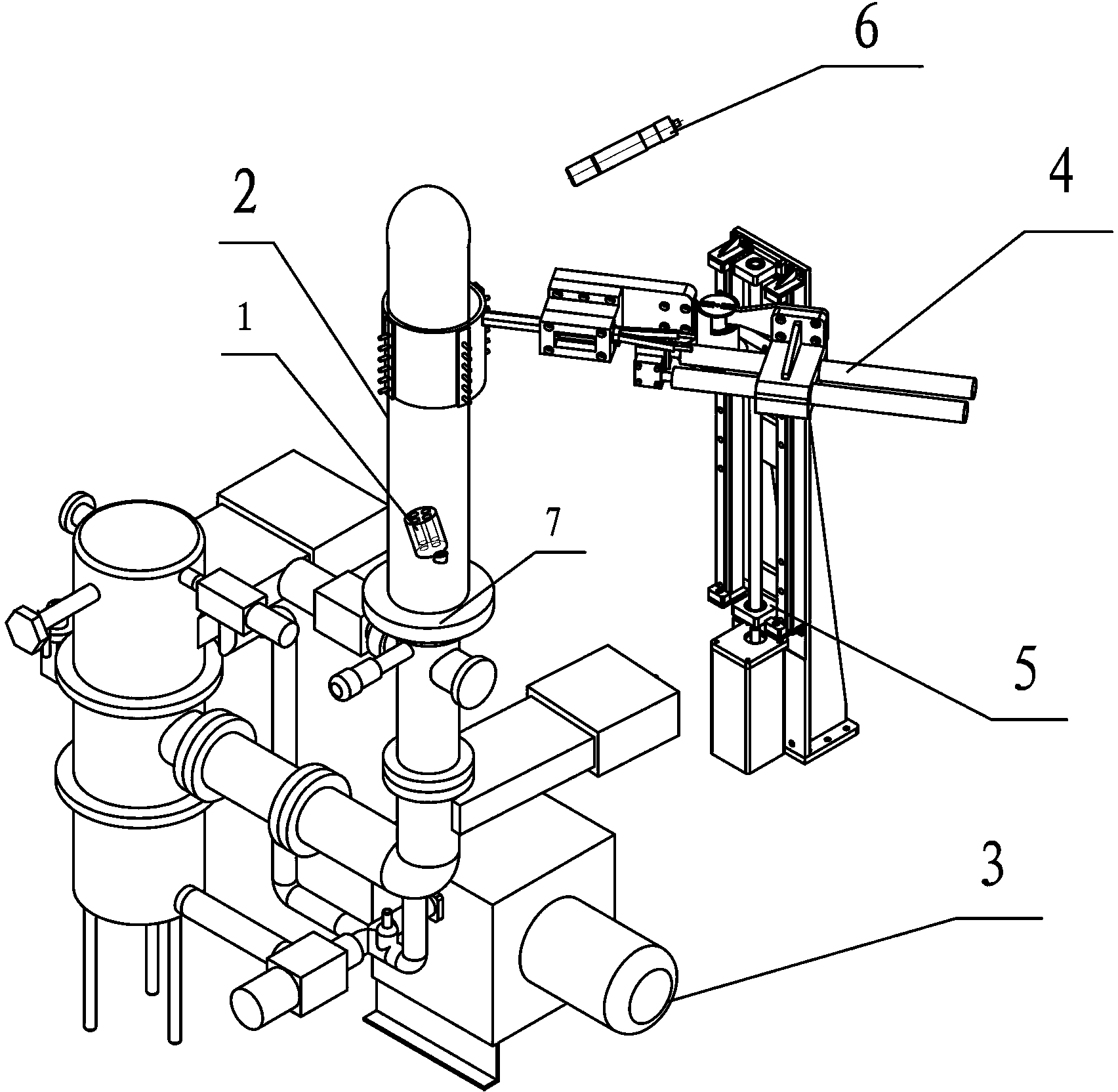

[0018] like figure 1 Shown is a casting device for a closed glass X-ray fixed oxygen-free copper anode target, including a graphite mold 1, a quartz bell jar 2, a vacuum exhaust table 3, an intermediate frequency induction power supply 4, an induction coil moving table 5, and a composite high-speed digital Infrared thermometer 6, the quartz bell jar 2 is installed on the vacuum exhaust table 3 through the sealing flange 7, the graphite mold 1 is placed in the quartz bell jar 2; the intermediate frequency induction power supply 4, the The induction coil moving table 5 and the composite high-speed digital infrared thermometer 6 are all arranged on the vacuum exhaust table 3, and the induction coil of the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com