A device and application for preparing metal semi-solid slurry

A semi-solid slurry and metal technology, applied in the field of material science, can solve the problems of high energy consumption, long preparation time, and poor effect of grain refinement, and achieve easy parameter control, simple operation, and grain refinement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

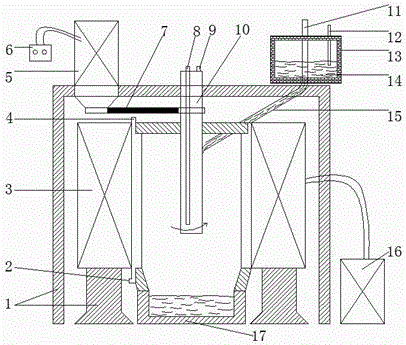

[0027] The device for preparing metal semi-solid slurry described in this embodiment includes: a support frame 1, a magnetic field generator 3, a speed regulating motor 5, a speed controller 6, a transmission belt 7, a rotating rod 10, a graphite stopper rod 11, a thermocouple 12, The furnace 13, the runner 15, the current controller 16, the crystallizer 17, the magnetic field generator 3, the speed regulating motor 5, and the furnace 13 are fixed on the support frame 1, and the rotating rod 10 is fixed on the support frame 1 and located on the magnetic field generator 3 In the inner cavity of the inner cavity, the speed regulating motor 5 is connected with the rotating rod 10 through the transmission belt 7, and the furnace 13 is provided with a graphite stopper rod 11, a thermocouple 12, and a runner 15, and the runner 15 communicates with the furnace 13, and the runner 15 The inlet is located at the lower end of the graphite stopper rod 11, the outlet of the runner 15 faces ...

Embodiment 2

[0035] The device for preparing metal semi-solid slurry described in this embodiment includes: a support frame 1, a magnetic field generator 3, a speed regulating motor 5, a speed controller 6, a transmission belt 7, a rotating rod 10, a graphite stopper rod 11, a thermocouple 12, The furnace 13, the runner 15, the current controller 16, the crystallizer 17, the magnetic field generator 3, the speed regulating motor 5, and the furnace 13 are fixed on the support frame 1, and the rotating rod 10 is fixed on the support frame 1 and located on the magnetic field generator 3 In the inner cavity of the inner cavity, the speed regulating motor 5 is connected with the rotating rod 10 through the transmission belt 7, and the furnace 13 is provided with a graphite stopper rod 11, a thermocouple 12, and a runner 15, and the runner 15 communicates with the furnace 13, and the runner 15 The inlet is located at the lower end of the graphite stopper rod 11, the outlet of the runner 15 faces ...

Embodiment 3

[0043] The device for preparing metal semi-solid slurry described in this embodiment includes: a support frame 1, a magnetic field generator 3, a speed regulating motor 5, a speed controller 6, a transmission belt 7, a rotating rod 10, a graphite stopper rod 11, a thermocouple 12, The furnace 13, the runner 15, the current controller 16, the crystallizer 17, the magnetic field generator 3, the speed regulating motor 5, and the furnace 13 are fixed on the support frame 1, and the rotating rod 10 is fixed on the support frame 1 and located on the magnetic field generator 3 In the inner cavity of the inner cavity, the speed regulating motor 5 is connected with the rotating rod 10 through the transmission belt 7, and the furnace 13 is provided with a graphite stopper rod 11, a thermocouple 12, and a runner 15, and the runner 15 communicates with the furnace 13, and the runner 15 The inlet is located at the lower end of the graphite stopper rod 11, the outlet of the runner 15 faces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com