Rotary knife, manufacturing method thereof, and rotary cutting device

A manufacturing method and technology of rotating knife, applied in thin material processing, metal processing, sending objects, etc., can solve problems such as sheet separation, low installation accuracy, damage to cutting tool characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

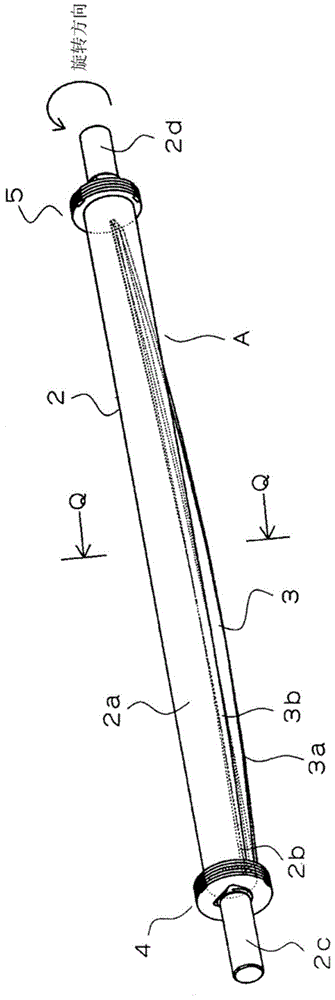

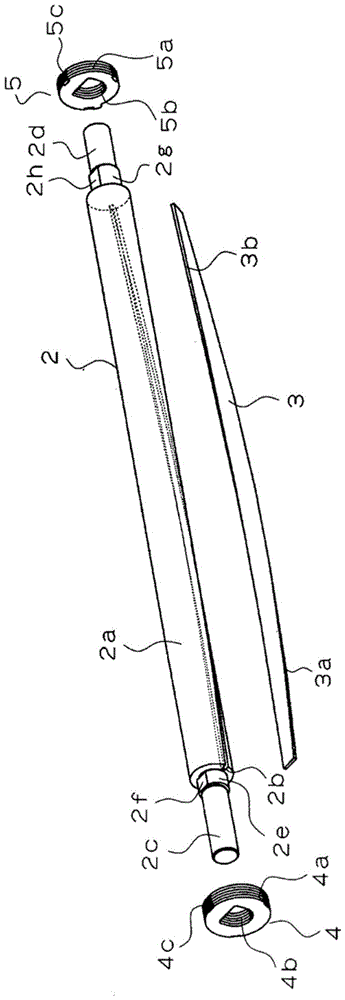

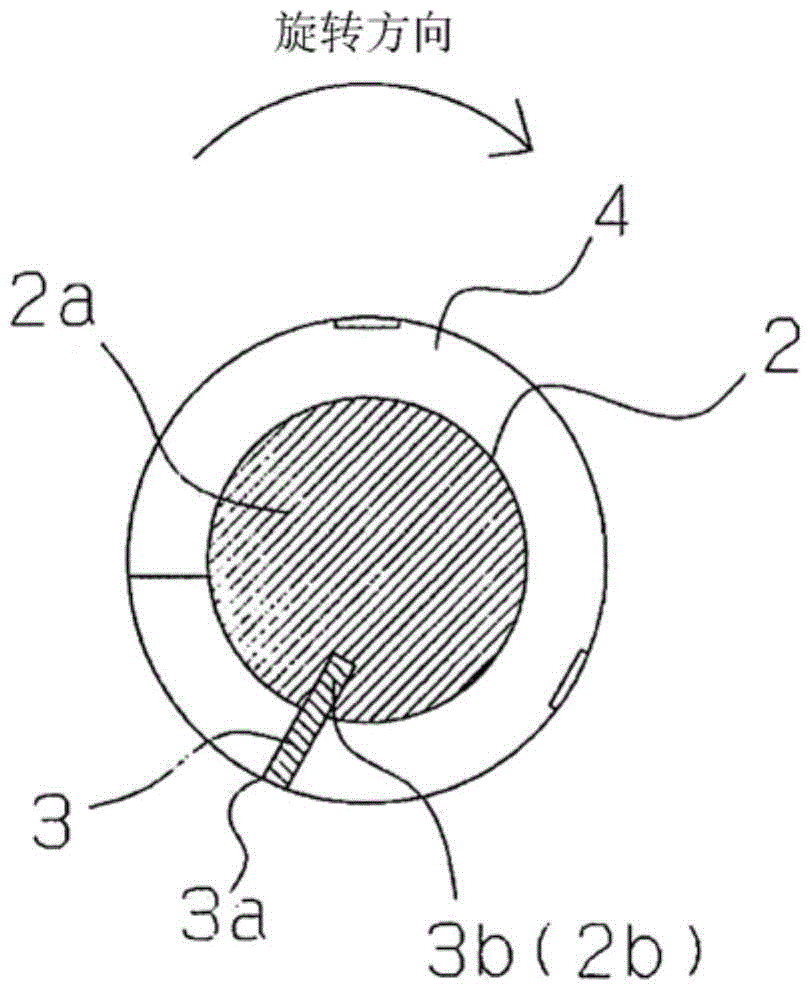

[0040] The rotary knife of the present invention is a rotary knife suitable for sheet cutting, and is a rotary knife in which a blade made of a strip material extends in the longitudinal direction of a bar-shaped shank having a rotation axis.

[0041] In the case of applying a plate material to the blade of a rotary knife as in the prior art, it is necessary to have the simplification and high precision of the assembly with the handle, and the necessary and sufficient mechanical strength as the blade, so that the posture of the blade can be accurately maintained and the Make high-quality cuts. Therefore, it is important that the sheet is not easily lifted from the handle and that the sheet is not only deformed not only plastically but also elastically when fitted to the handle.

[0042] On the basis of fully considering these points, the rotary knife application of the present invention has the strip-shaped material with the above-mentioned special properties that is good flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com