High precision ferrule punching positioning forming die cutting device

A forming mold and high-precision technology, which is applied in metal processing and other directions, can solve the problems of inaccurate product size and inaccurate material positioning, and achieve the effects of low production cost, simple equipment structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

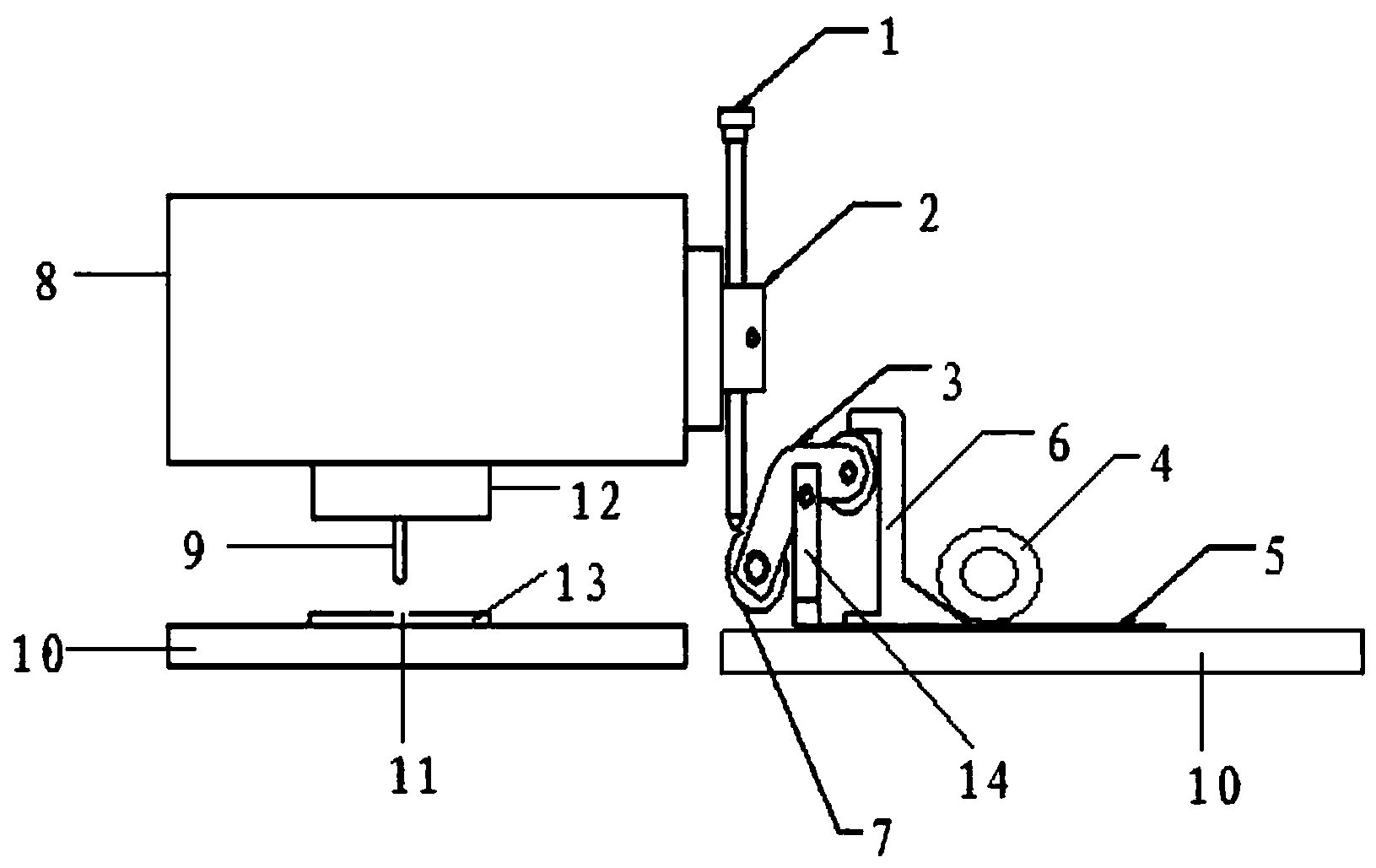

[0015] The main structure of this embodiment includes two functional parts, the sleeve punching matching circular motion device and the template mold positioning device. Material round roller 4, stamping material 5, fixed bearing 6, pulley 7 and fixed shaft 14, fixed nut bracket 2 is rotatably interspersed with height adjustment nut 1, and the position of height adjustment nut 1 in fixed nut bracket 2 can be up and down Adjustment, the fixed nut bracket 2 is fixedly arranged in the center of the template 8 on the die-cutting machine; the tip of the height adjustment nut 1 is aligned with the pulley 7, and the pulley 7 is rotatably connected to the front end of the lever tripod 3, and the lever tripod 3 is rotatably connected to the On the fixed shaft 14 of the bottom plate 10 of the die-cutting machine, the end of the lever tripod 3 is fixedly connected with a fixed force bearing 6, and the front edge of the fixed force rotating shaft 6 is fixedly placed with a stamping pull ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com