Vehicle-mounted numerical control straw mat machine and weaving method thereof

A grass curtain machine and vehicle-mounted technology, which is applied in mechanical equipment, sugarcane machining, etc., can solve the problems of labor failure, waste of manpower and material resources, waste of agricultural resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

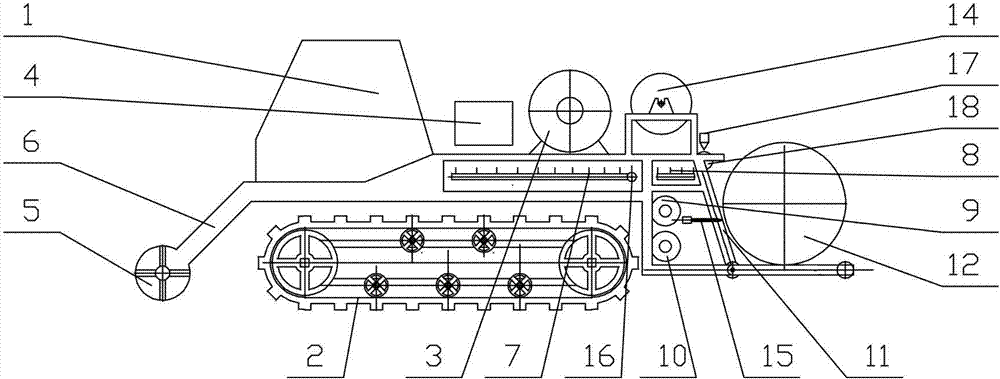

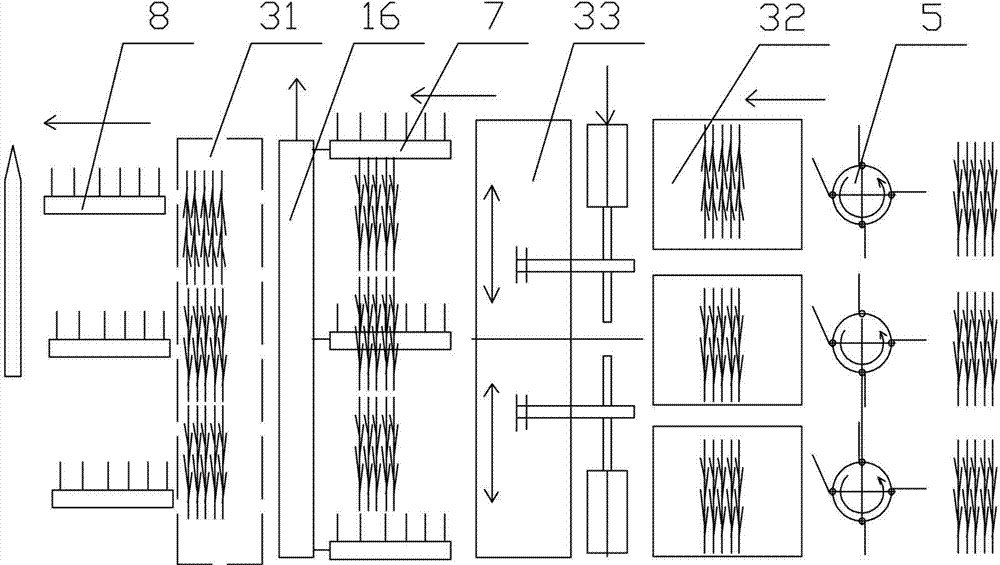

[0027] Such as figure 1 , image 3 and Figure 4 As shown, a vehicle-mounted numerically controlled grass curtain machine, the whole vehicle is electrically driven, and the vehicle body is provided with a driver's cab 1, a driving wheel 2, a generator set 3 and an electric drive distribution control system 4 connected to the generator set 3; The bottom of the cab 1 is provided with a ground straw picker 5, and the top of the ground straw picker 5 is connected with the grass feeding device through the grass distribution channel 6, and the end of the grass feeding device is successively provided with a straw weaving device 15 and a straw curtain roll. The drive system 11; the car body is provided with a wire supply device 14, and the wire on the wire supply device 14 is connected with the grass weaving device 15.

[0028] The structure of the grass feeding device is that a primary numerical control grass feeding board 7 is provided above the channel 6 of the numerically contro...

Embodiment 2

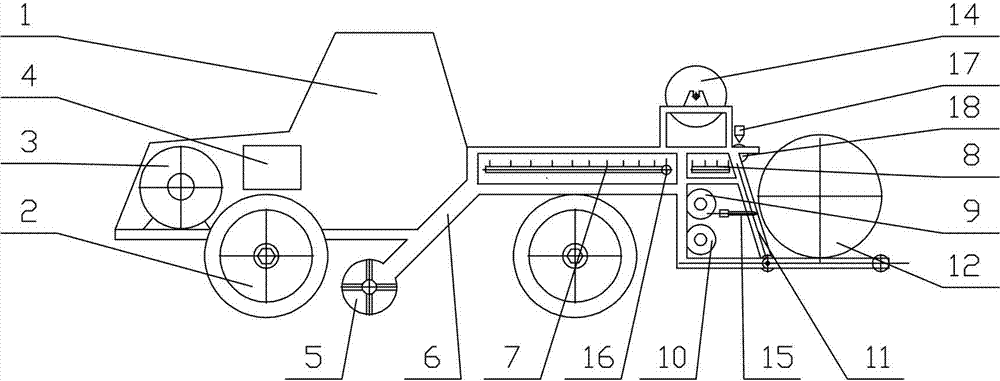

[0036] Such as figure 2 As shown, except that the driving wheel 2 is a walking wheel type structure for traveling on complex ground, all the other structures are the same as the embodiment.

[0037] The vehicle-mounted numerical control straw curtain machine carries out the method for weaving straw curtains, comprising the following steps:

[0038] 1) The electric drive distribution control system 4 controls the driving wheel 2 to advance in the paddy field, and ensures that the width of the ground straw picker 5 is the width of a three-way to multi-way paddy field, which depends on the width of the straw mat weaving;

[0039] 2) Start the straw picker 5 on the ground, and the straw will be drawn into the grass distribution channel 6, and the sensor in the grass distribution channel 6 will sense the direction of the straw entering the two sides of the road. The electric control system 4 controls the straw transfer belt 32 to change the direction of the straw stalk to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com