Plastic pipe extruding opening mold

A technology for plastic pipes and extrusion ports, which is applied in the field of plastic pipe extrusion dies, can solve the problems of not being able to effectively and quickly improve the surface defects of plastic pipe extrusion, achieve stable effects, reduce difficulty and cost, and improve melt modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

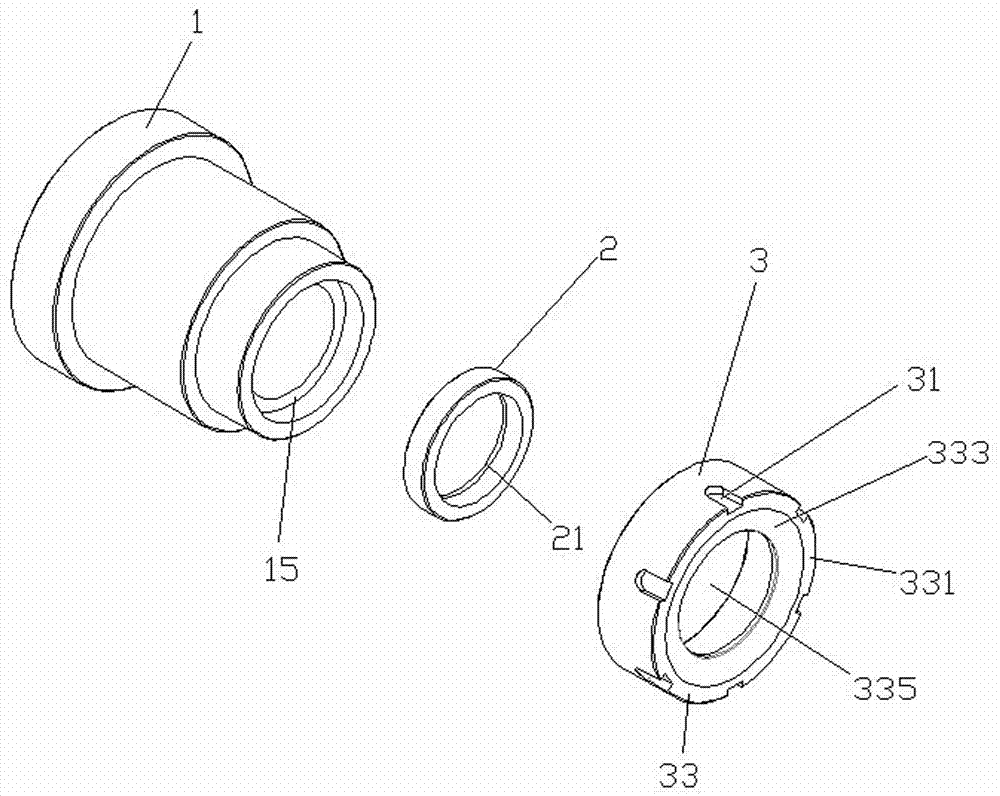

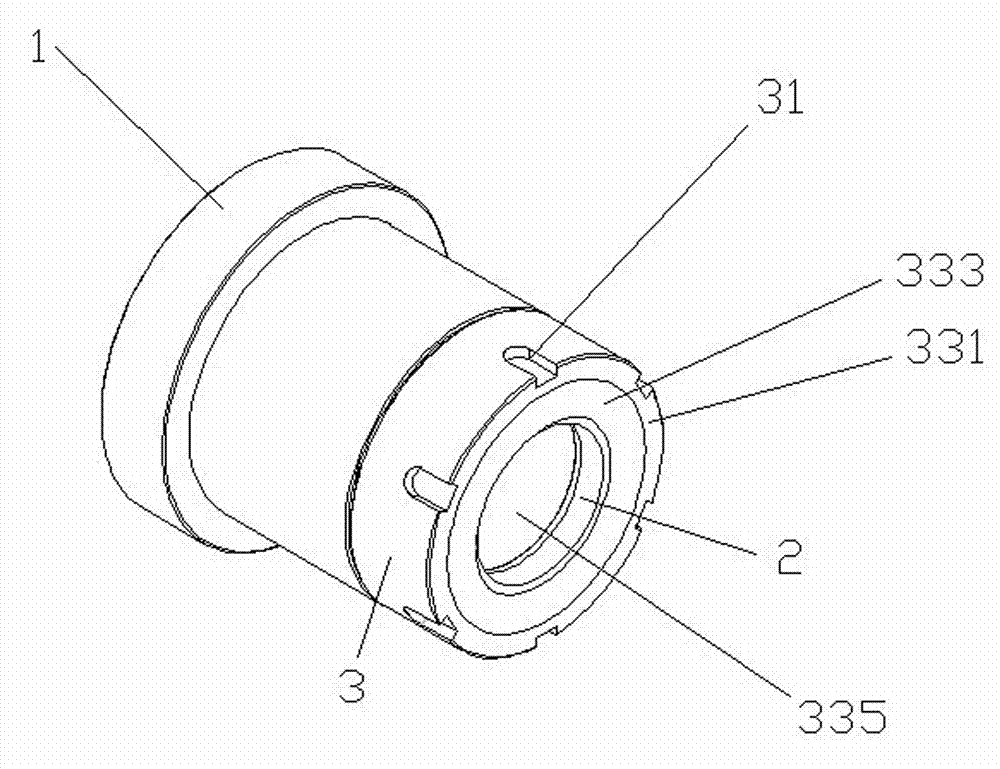

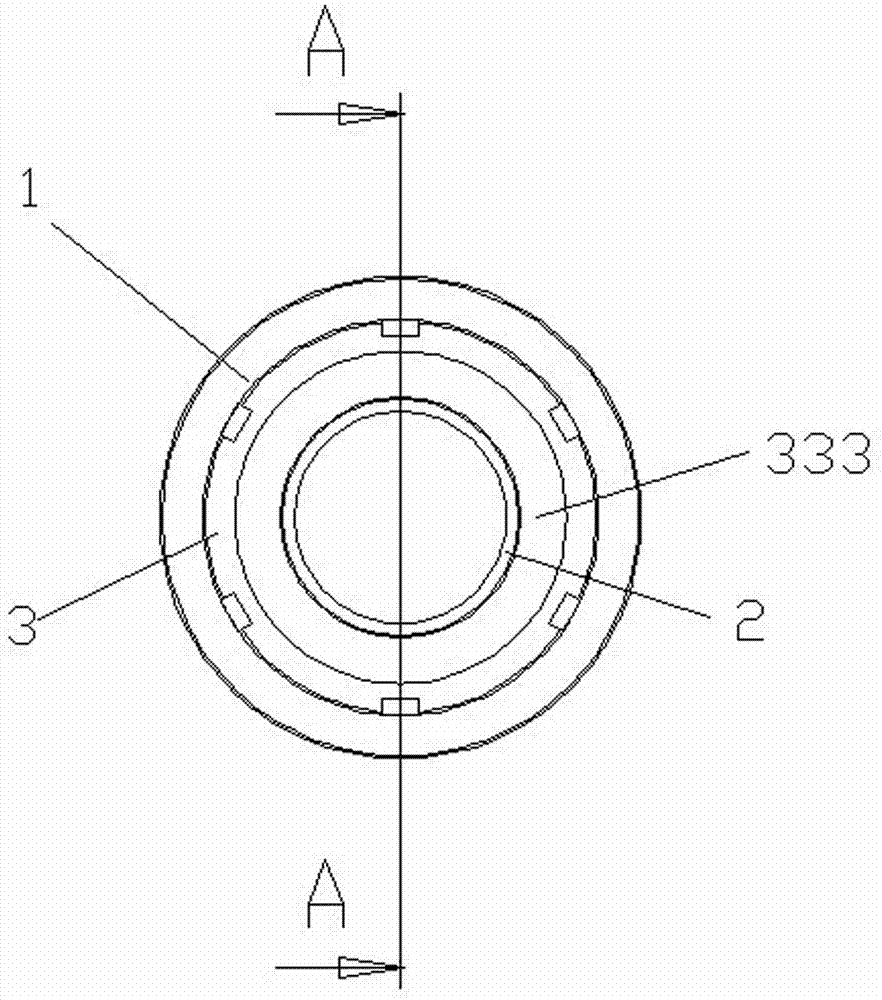

[0028] see Figure 1 to Figure 4 , a plastic pipe extrusion die, which includes a die body 1, a scraper ring 2, a die lock cover 3.

[0029] The die main body 1 is a rotating body, and its interior is hollow.

[0030] A compression channel 11 is dug into the rear end of the inner hollow part of the die main body 1 for the extruded molten material to pass through.

[0031] The compression channel 11 has a large diameter at the rear end and a small diameter at the front end, and the diameter gradually decreases when extending from the rear end to the front end.

[0032] The front end of the compression channel 11 is further extended to form a forming channel 13 with a constant diameter.

[0033] Therefore, the hollow part inside the die main body 1 is shaped like a bell mouth.

[0034] A circular mounting groove 15 is dug toward the outer wall at the front end of the forming channel 13 .

[0035] The outer surface of the side wall of the die main body 1 is provided with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com