Rear axle housing with high-intensity brake bottom plates

A brake floor, high-strength technology, applied in the direction of brakes, brake parts, brake components, etc., can solve problems such as affecting the trouble-free working time of the axle, hidden quality problems of components, increasing the gross weight of the brake floor, etc. Conducive to production management and after-sales maintenance, eliminating organizational defects and improving school performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

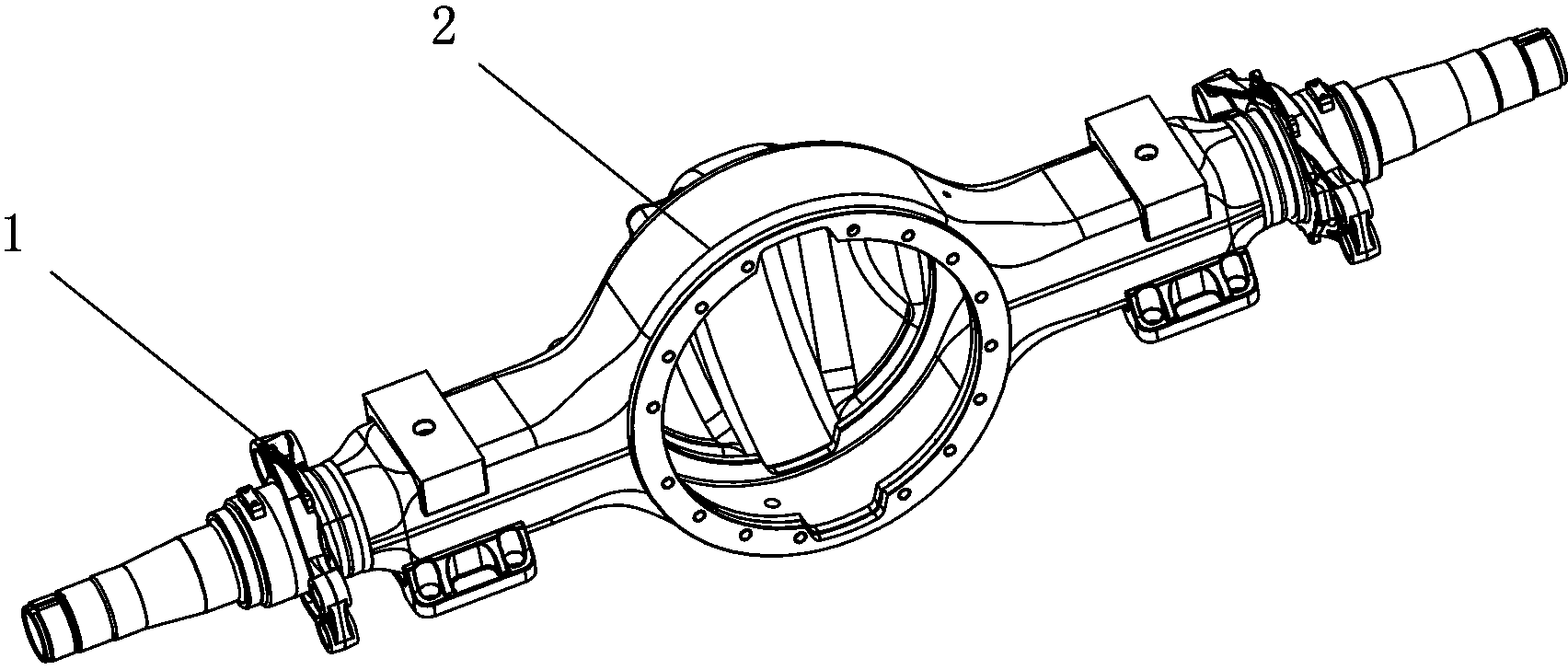

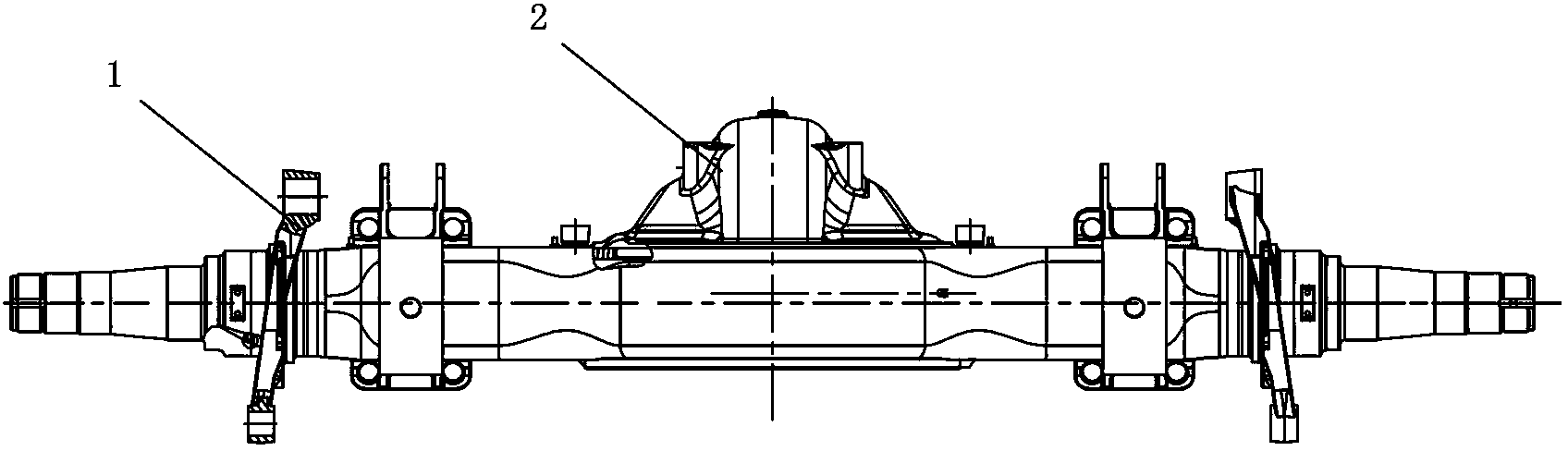

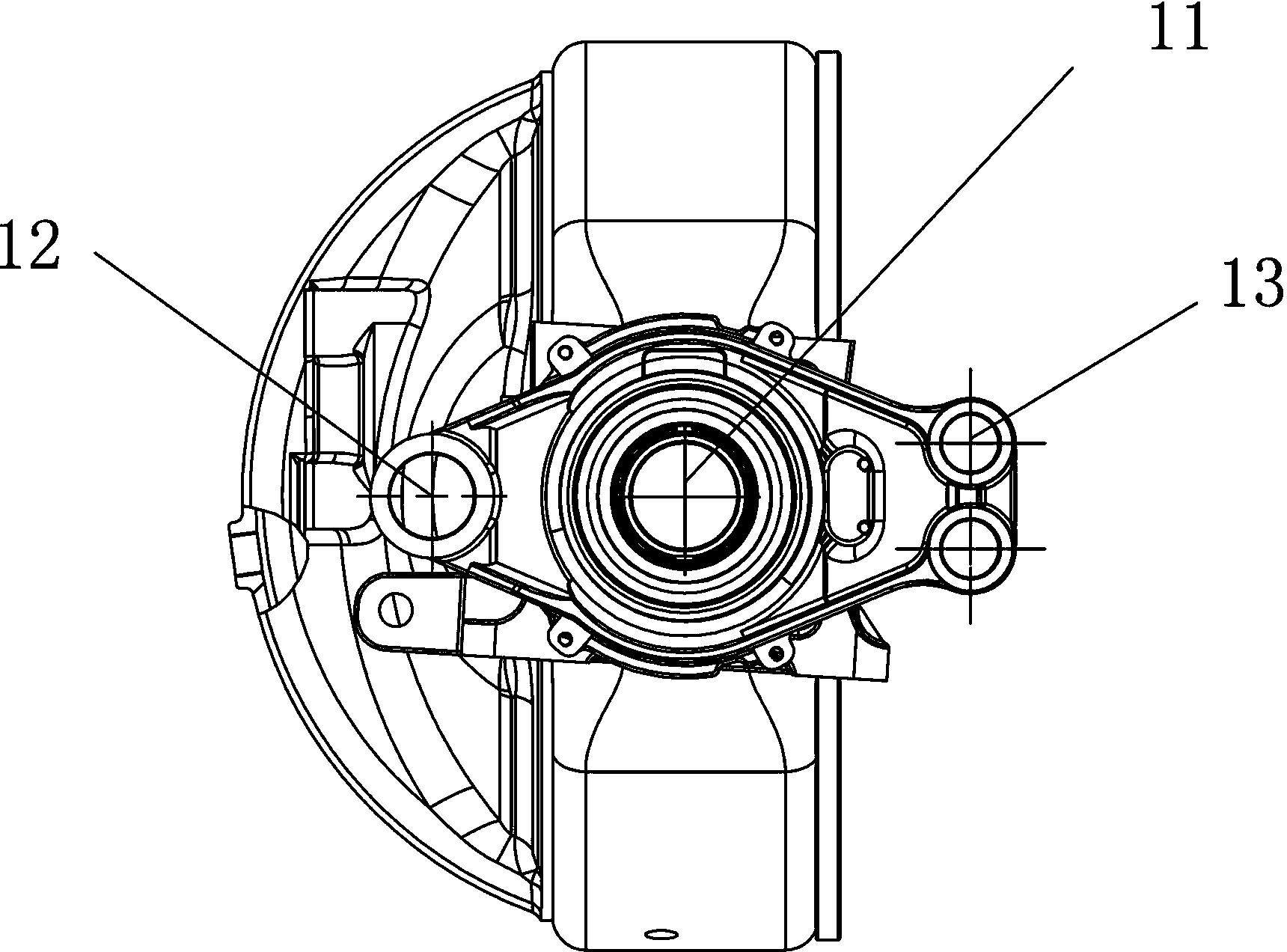

[0016] like Figure 1-3 As shown, the rear axle housing of the high-strength brake floor of the present invention includes a housing 2, and a pair of brake floor 1 is symmetrically installed on the mounting positions of the flanges at both ends of the casing, and the brake floor 1 is provided with a central axis hole. 11. The central shaft hole 11 is adapted to the outer contour of the flange installation position of the housing, so the brake base plate can be inserted into the flange installation position from both ends of the housing, and then along the outer contour of the central shaft hole A circle of full welding on round welding or welding on an arc-shaped fillet weld. One end of the brake base plate 1 is provided with a supporting pin hole 13, and the other end of the plate body of the brake base plate is provided with a cams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com