Safe collision-preventing device of industry material handling vehicle

A technology for handling vehicles and anti-collision, which is applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc. It can solve the problems that cannot be used in the industrial field environment, high equipment value, small detection area, etc., and achieve convenient battery The effect of maintenance and management, strong environmental adaptability, easy to move and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

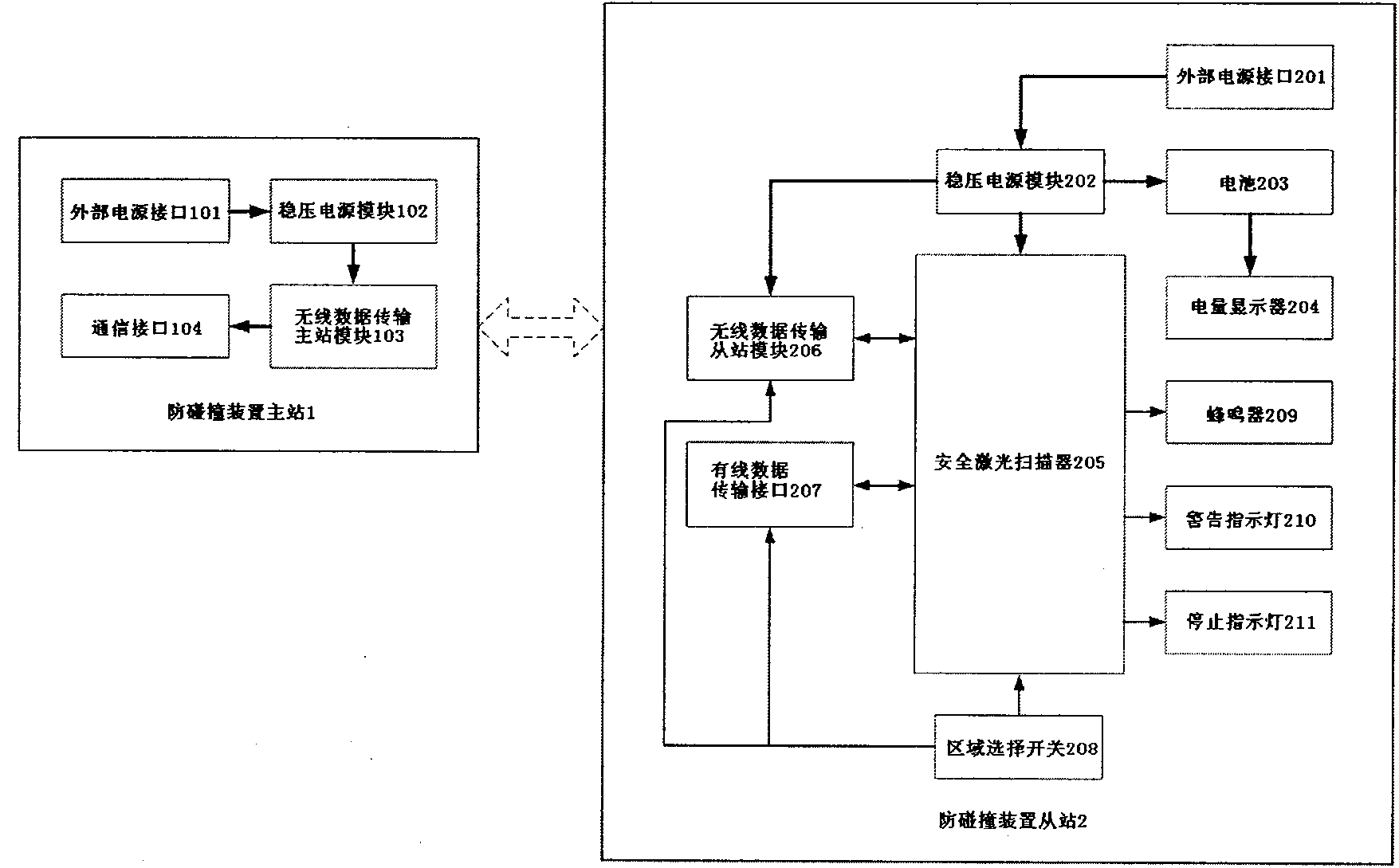

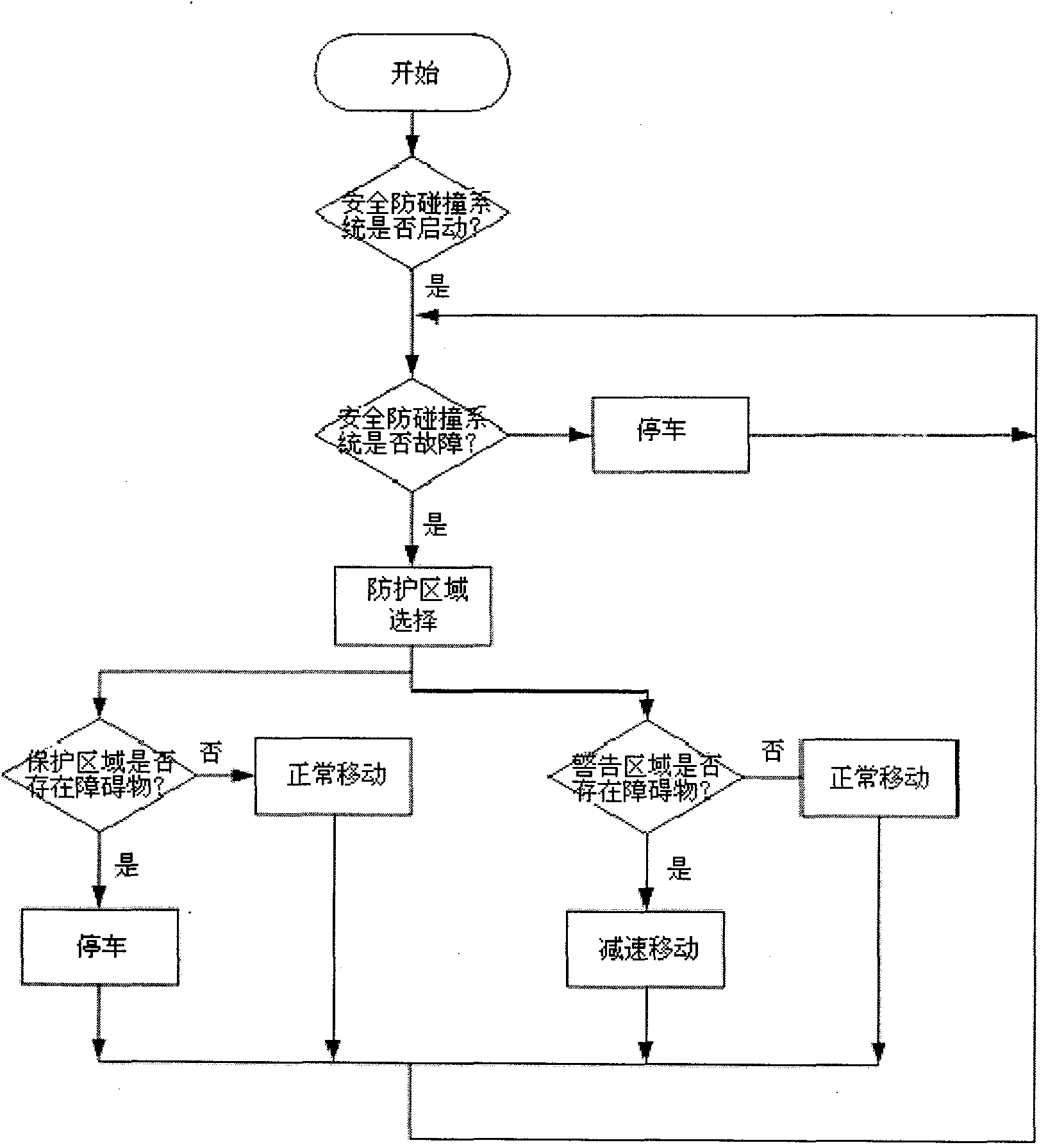

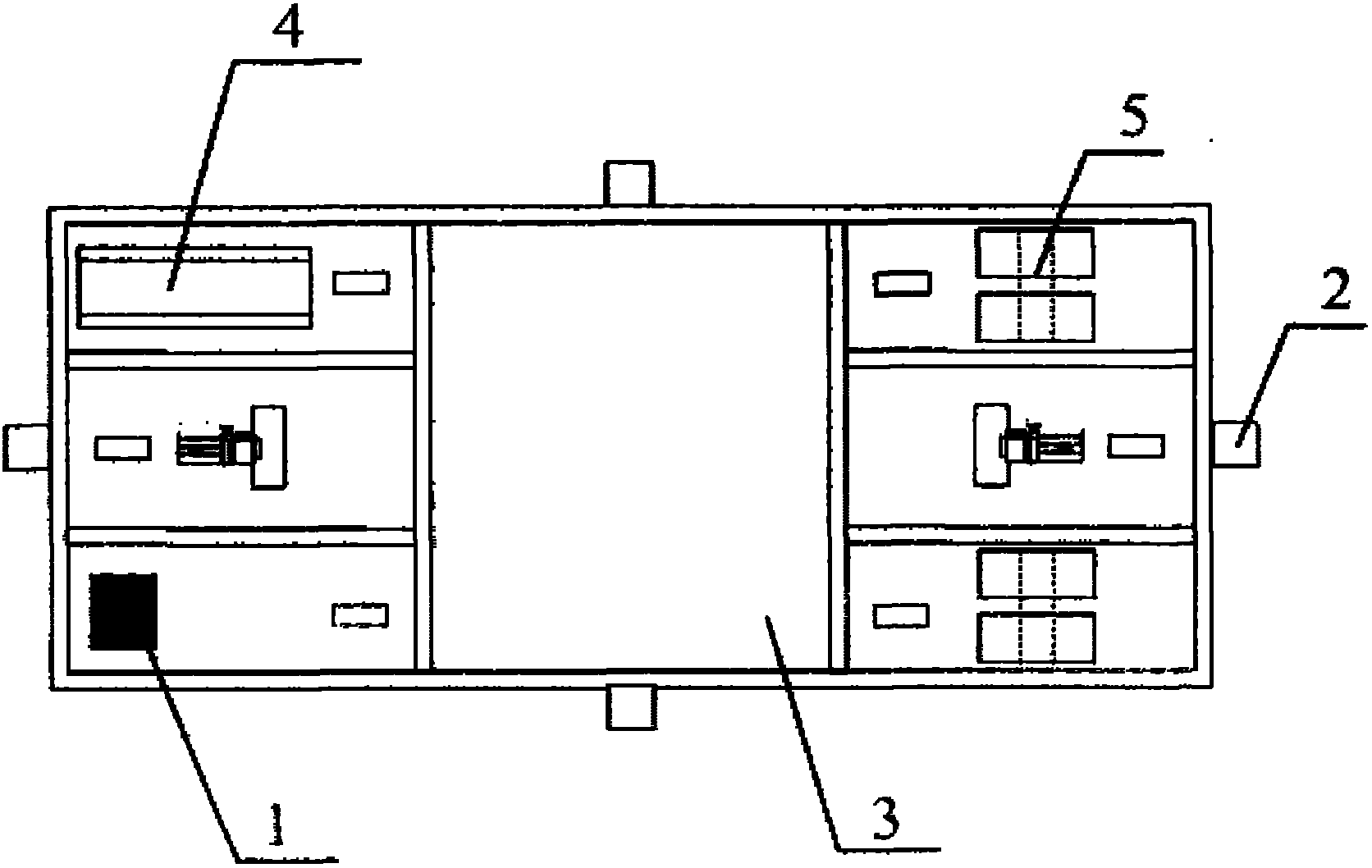

[0040] In order to solve the problems in the prior art, the present invention provides a safety anti-collision device for a factory material handling vehicle, which is characterized in that it includes: a safety anti-collision device master station 1 and at least one safety anti-collision device slave station 2; the safety anti-collision device The main station 1 of the collision device and the slave station 2 of the safety anti-collision device are sealed separately, and a handle is set on the box; 2 To form a set of safety anti-collision devices, the wireless frequencies of the wireless data transmission master module 203 and the wireless data transmission slave module 206 must be the same.

[0041] Multiple safety a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com