Ground friction drive rotating platform for bumper conveying

A friction drive and bumper technology, applied in the field of conveyors, can solve the problems of short bumper trolley pitch, unusable switch structure, dense friction drive layout, etc., and achieves the effects of ingenious structure, low manufacturing cost and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

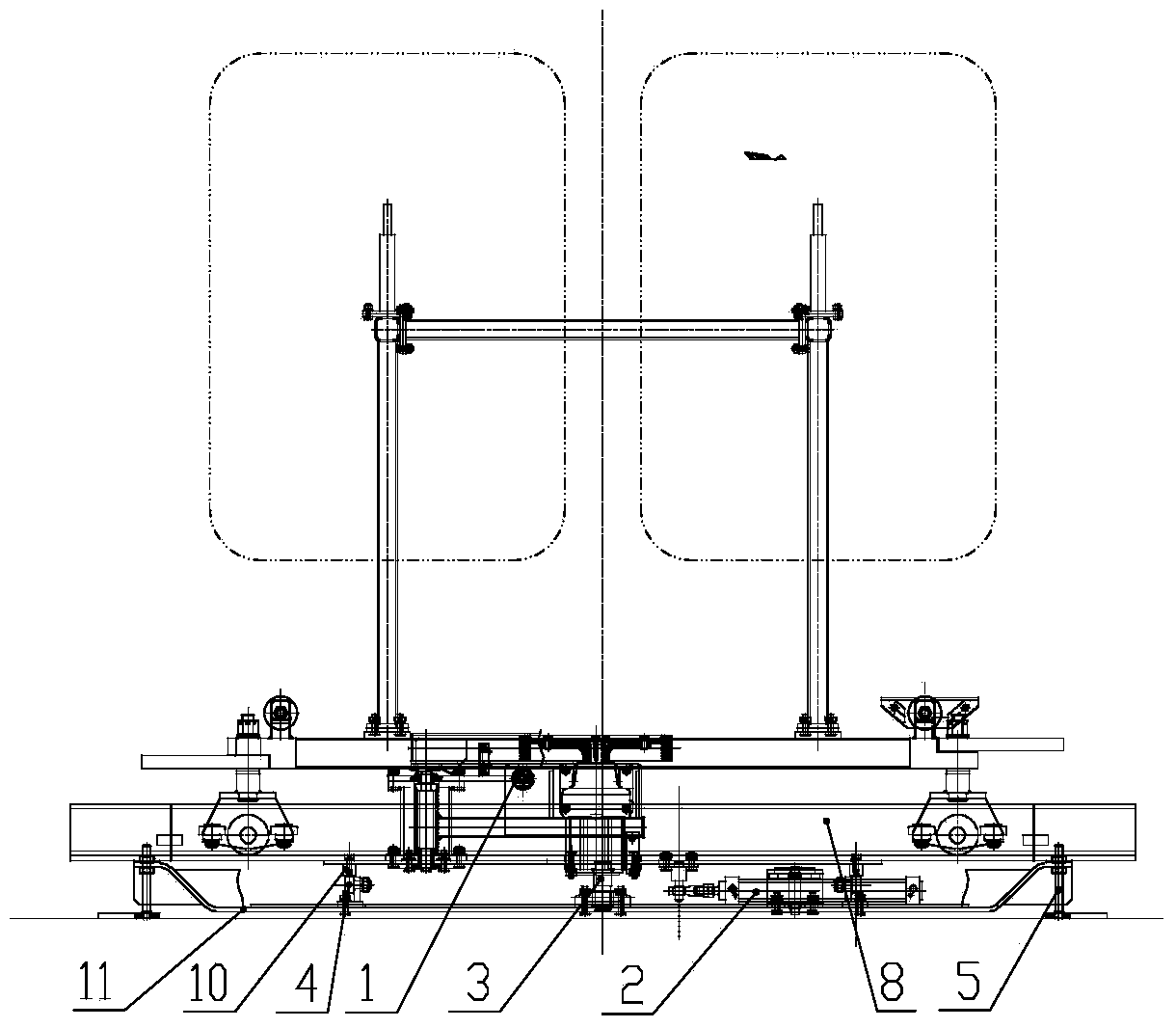

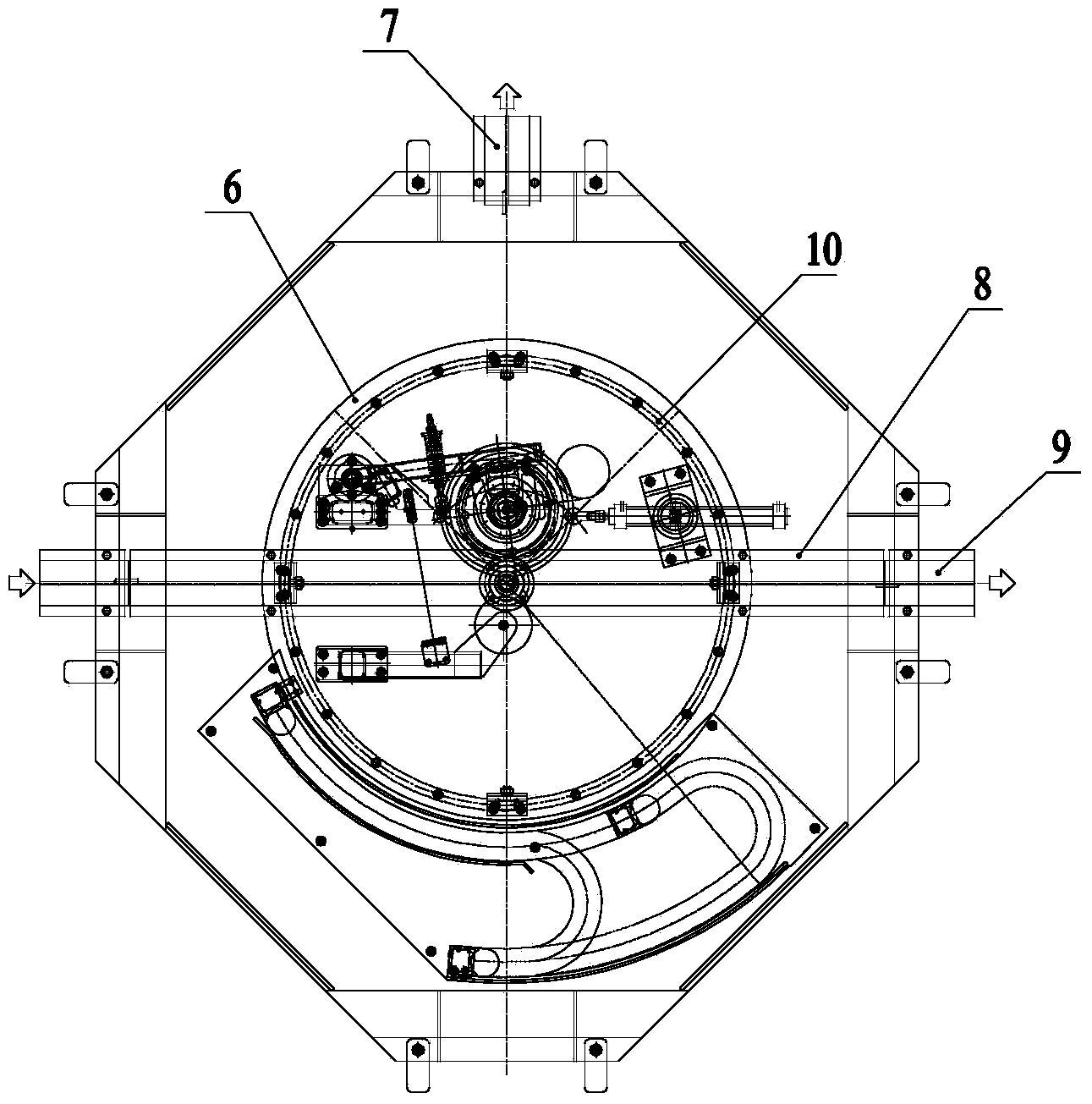

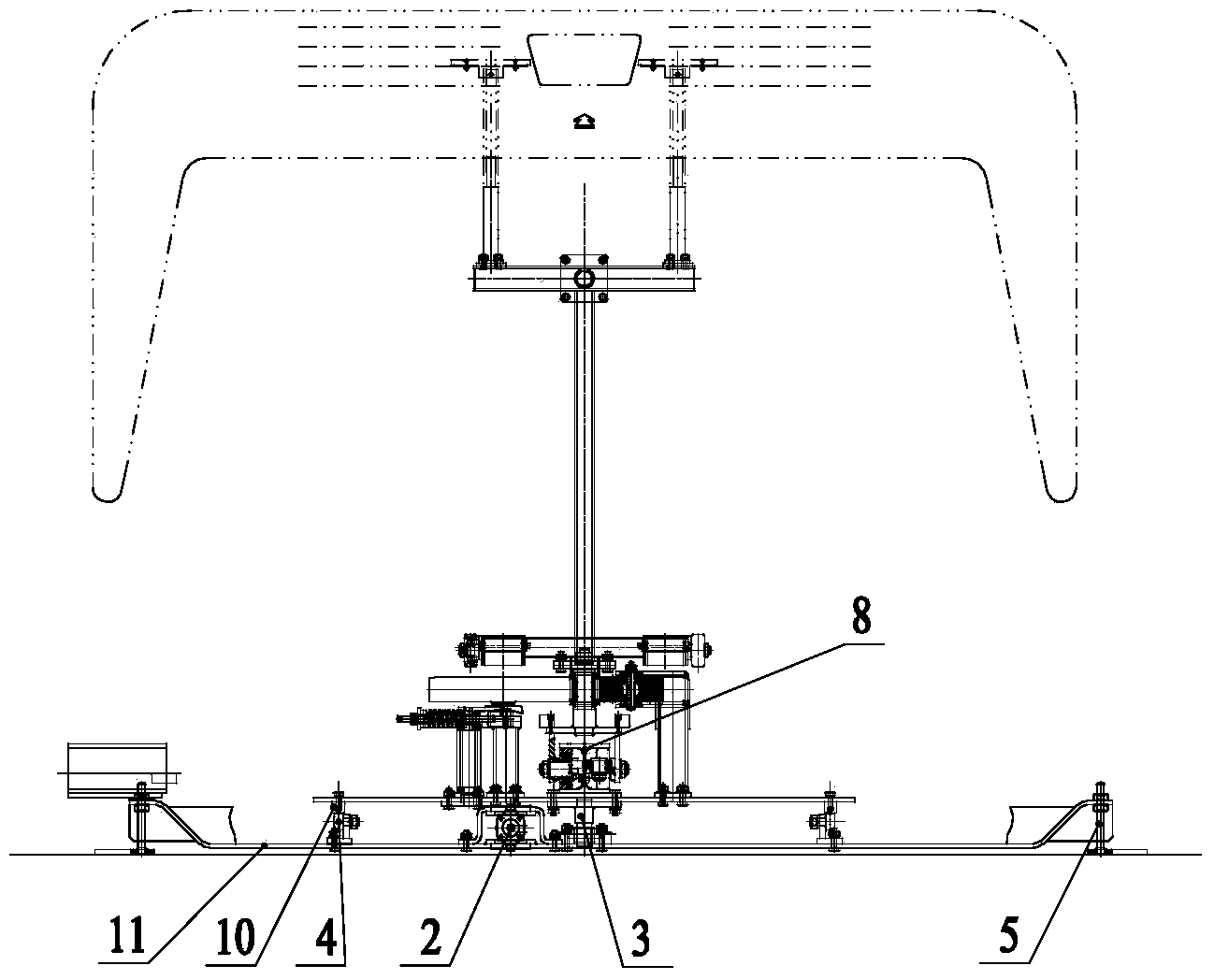

[0013] As shown in the figure: the bumper ground friction-driven turntable of the present invention is mainly composed of a friction drive 1, a cylinder assembly 2, a rotating shaft assembly 3, a roller assembly 4, an adjusting foot 5, a rotating disk 6, a rotating track 8, and a rotating guide rail 10 It is composed of parts such as the bottom fixed frame 11.

[0014] As shown in the figure, the rotating disk 6 is supported and installed on the bottom fixed frame 11 through the rotating shaft assembly 3; the friction drive 1 and the fixed rail 8 are fixed on the rotary disk 6, and the friction drive 1 is arranged beside the fixed rail 8; The cylinder assembly 2 is arranged under the rotating disk 6, the cylinder body of the cylinder assembly 2 is fixed on the bottom fixed frame 11, and the piston rod end of the cylinder assembly 2 is connected to the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com