Rotor type car dumper

A dumper and rotor-type technology, which is applied in the direction of mechanical equipment, loading/unloading, and fluid pressure actuating devices, can solve the problems of accelerated hydraulic pipeline joint loosening, increased hydraulic failure rate, and line insulation wear, etc., to reduce oil leakage phenomenon, improve operating efficiency, and reduce maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

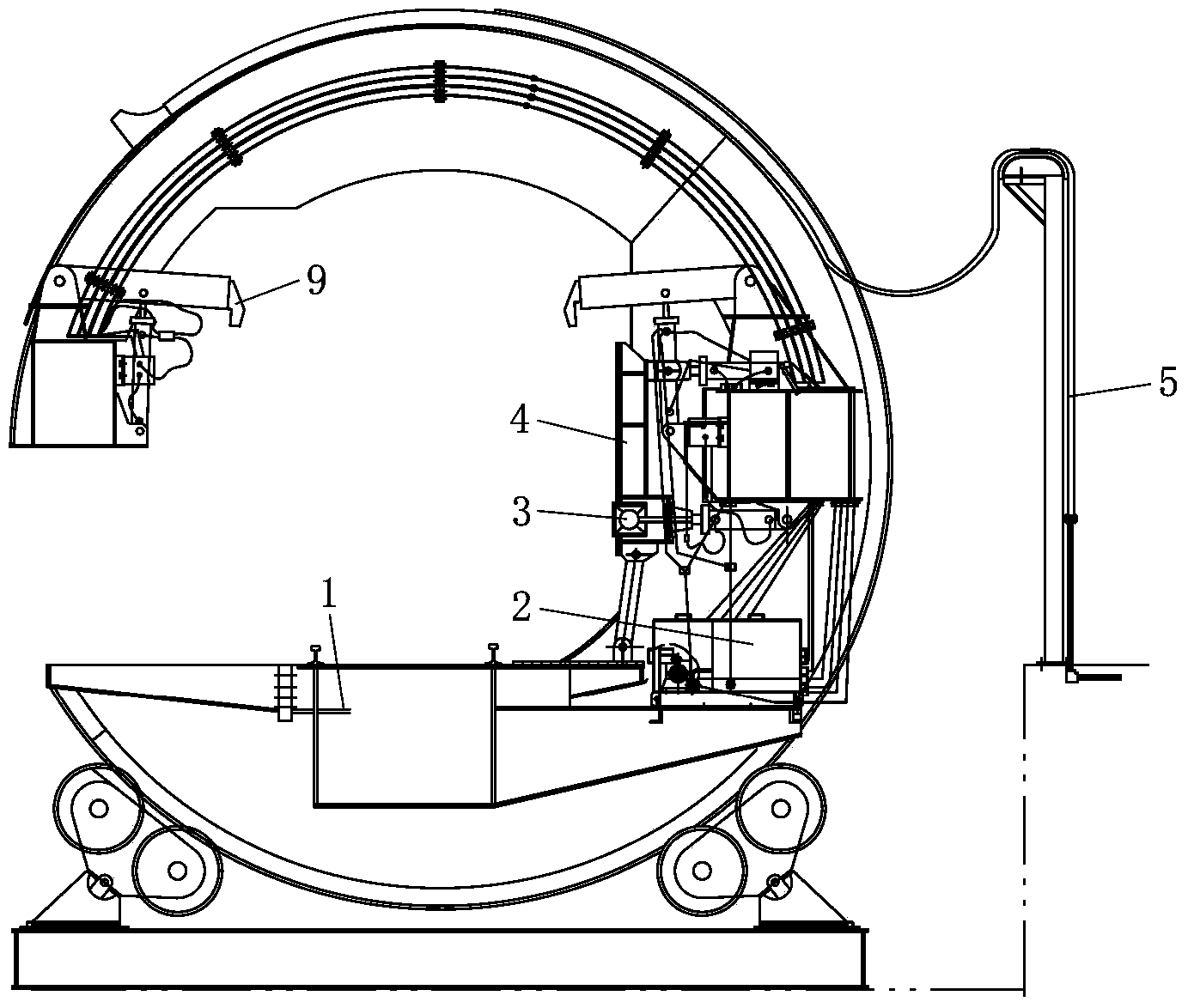

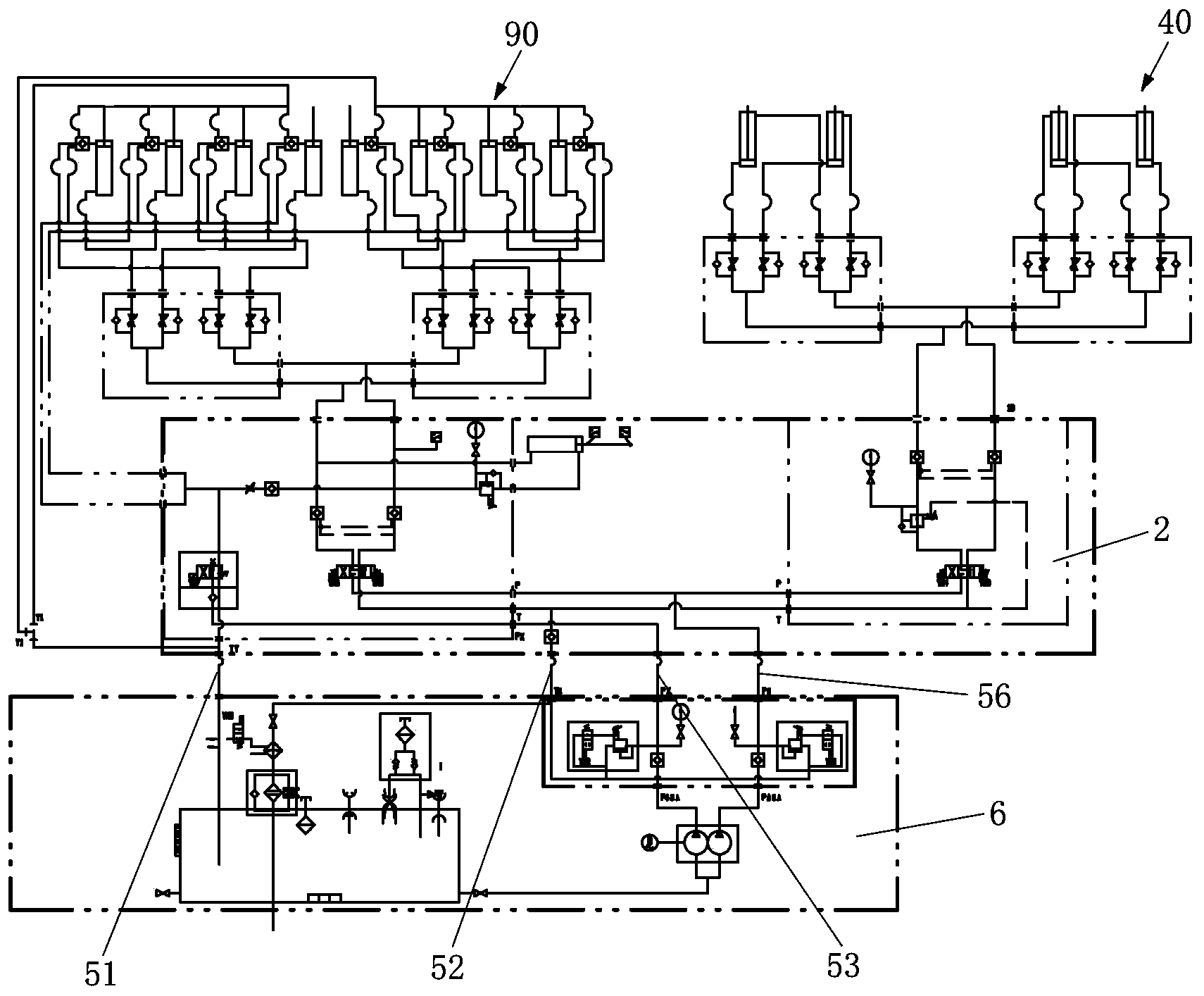

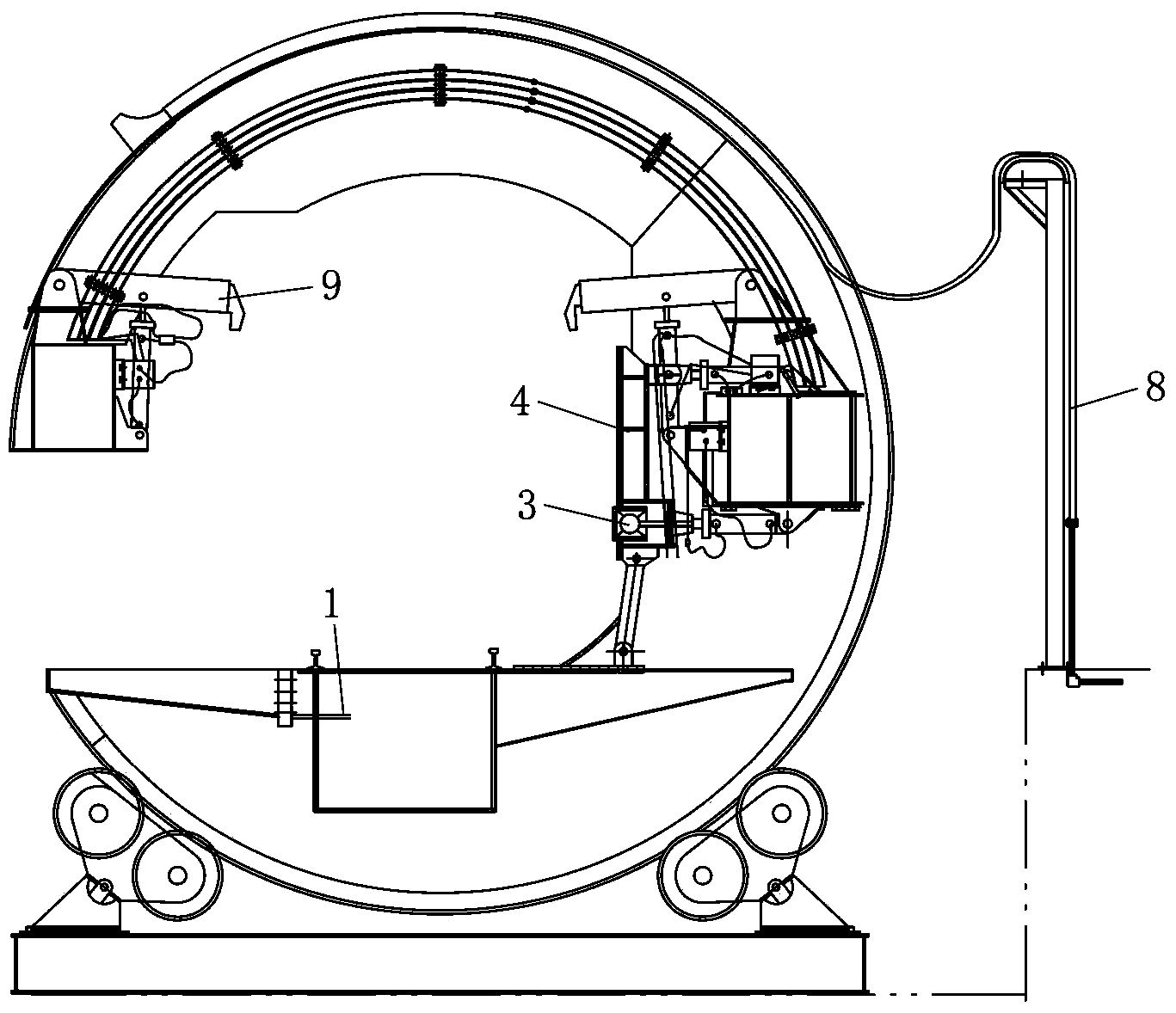

[0023] refer to image 3 with Figure 4 , image 3 is a schematic structural diagram of a rotor dumper according to an embodiment of the present invention, Figure 4 yes figure 1 The hydraulic schematic diagram of the hydraulic system of the rotor dumper shown in .

[0024] According to an embodiment of the present invention, a rotor-type dumper is provided, which includes a body 1, a pressing device 9 installed on the body 1 and a car-resting device 4, which are installed in the body 1 and used to drive the pressing device. Vehicle device 9 and the hydraulic component assembly of vehicle device 4, hydraulic pump station and hydraulic valve station and various hydraulic pipelines. The car pressing device 9 mainly moves up and down to clamp the compartm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com