A process for producing al2o3 balls

A process and ball forming technology, which is applied in the field of Al2O3 ball production, can solve the problems of unsatisfactory and harsh raw material requirements, and achieve the effect of qualified product quality and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

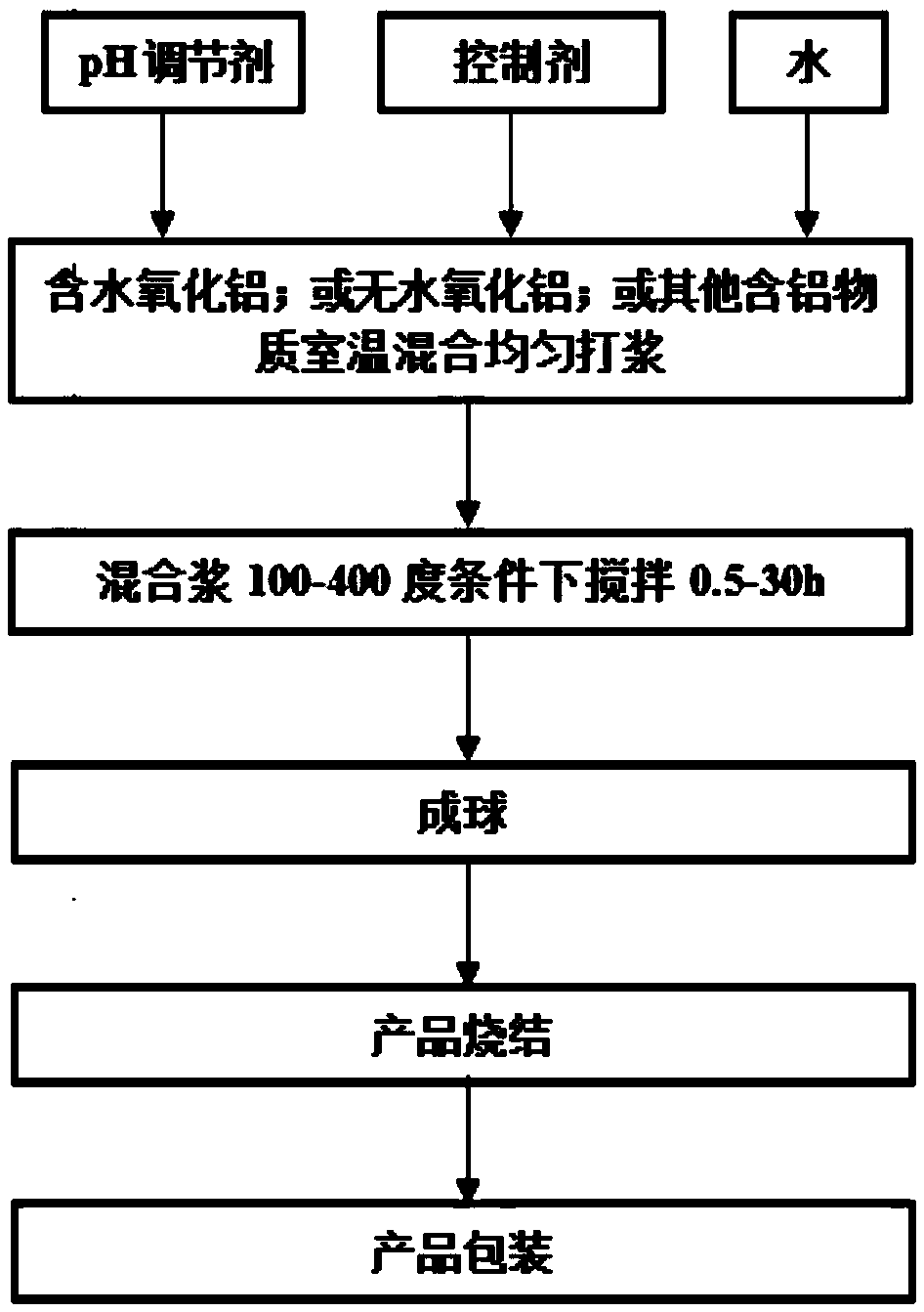

Method used

Image

Examples

Embodiment 1

[0025] In terms of molar ratio, 25.6 moles of dry gibbsite produced by Bayer process is used as aluminum-containing raw material, 0.25 moles of ammonium sulfate is used as grain control agent, and 5.12 moles of aluminum-containing hydrate (the crystal water is 0.56 moles) is used as orientation control agent , then add water and mix evenly, and adjust the pH value to about 3 through a pH regulator; stir the above-mentioned mixture at room temperature at 100 rpm for 20 minutes, then raise the temperature to 180°C and keep it warm for 5 hours at a speed of 100 rpm; Centrifugal spray drying molding: the air inlet temperature is lower than 250°C, the air outlet temperature is controlled at 80-85°C; the water content is controlled at 4-8%. After roasting, the roasting temperature is 500-900 ° C, and the roasting time is 2-5 hours, and the alumina ball product is made.

Embodiment 2

[0027] In terms of molar ratio, 15 moles of gibbsite dehydration product (rh-type alumina) produced by Bayer process is used as aluminum-containing raw material, 1.0 moles of sodium sulfate is used as grain control agent, and acetic acid is used as pH regulator. Control agent; add water and mix evenly, adjust the pH to about 4, stir the above mixture at room temperature at 100 rpm for 20 minutes, then heat up to 180°C and keep warm at 100 rpm at 200°C 2h, through centrifugal spray drying: the air inlet temperature is lower than 300-450℃, the air outlet temperature is controlled at 80-115℃; the water content is controlled at 4-8%. After roasting: the roasting temperature is 500-900°C, and the roasting time is 2-5h to make alumina ball products.

Embodiment 3

[0029] In terms of molar ratio, 20 moles of gibbsite dehydration product (γ-type alumina) produced by Bayer process is used as aluminum-containing raw material, and 0.6 moles of sodium sulfate and ammonium sulfate mixed salt is used as grain control agent. After adding water and mixing evenly, pass pH Regulators ammonia water and sodium hydroxide adjust the pH to about 11, stir the above mixture at room temperature at 100 rpm for 20 minutes, then raise the temperature to 180°C and keep warm at 200°C for 2 hours at a speed of 100 rpm. Formed by centrifugal spray drying: the temperature of the air inlet is lower than 250°C, the temperature of the air outlet is controlled at 80-85°C; the water content is controlled at 4-8%. After roasting: the roasting temperature is 500-900°C, and the roasting time is 2-5h to make alumina ball products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com