A kind of negative temperature coefficient thermistor chip, thermistor and its preparation method

A technology of thermistor chip and negative temperature coefficient, applied in the direction of resistors with negative temperature coefficient, etc., can solve the problem of reducing the sensitivity of thermistor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] In this specific embodiment, the negative temperature coefficient thermistor chip is made of transition metal oxide powder sintered, and the transition metal oxide powder includes cobalt tetroxide Co 3 O 4 , manganese dioxide MnO 2 , yttrium trioxide Y 2 O 3 , Cr2O3 2 O 3 and / or titanium dioxide TiO 2 , the sum of the contents of each component is 100%.

[0015] Among them, transition metal oxides include chromium dioxide Cr 2 O 3 or titanium dioxide TiO 2 When the content ratio is (calculated by mole percentage):

[0016] Co 3 O 4 , 30%~70%;

[0017] MnO 2 , 20%~60%;

[0018] Y 2 O 3 , greater than 0 and less than or equal to 5%;

[0019] Cr 2 O 3 (or TiO 2 ), 5% to 20%.

[0020] When transition metal oxides include chromium oxide Cr 2 O 3 and titanium dioxide TiO 2 When the content ratio is (calculated by mole percentage):

[0021] Co 3 O 4 , 40% to 60%;

[0022] MnO 2 , 30%~50%;

[0023] Y 2 O 3 , greater than 0 and less than or equal ...

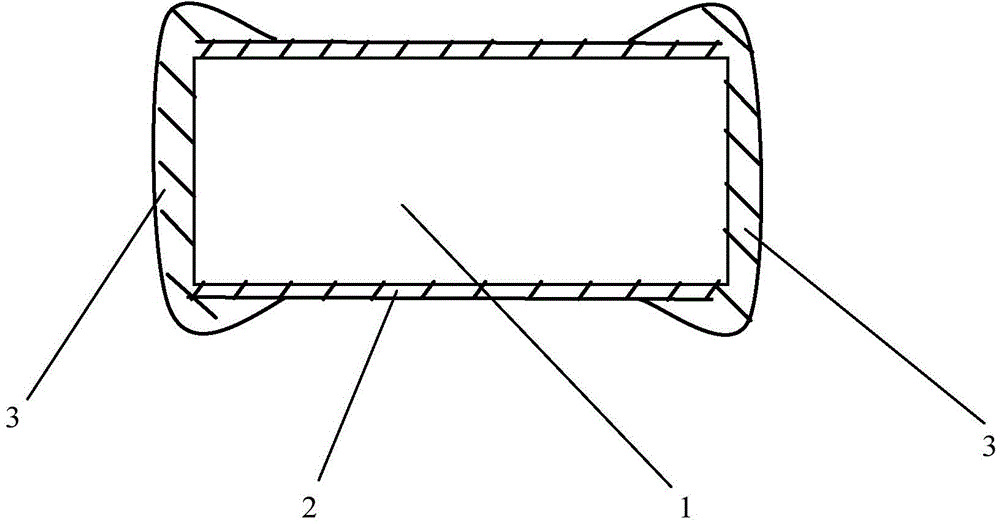

Embodiment 1

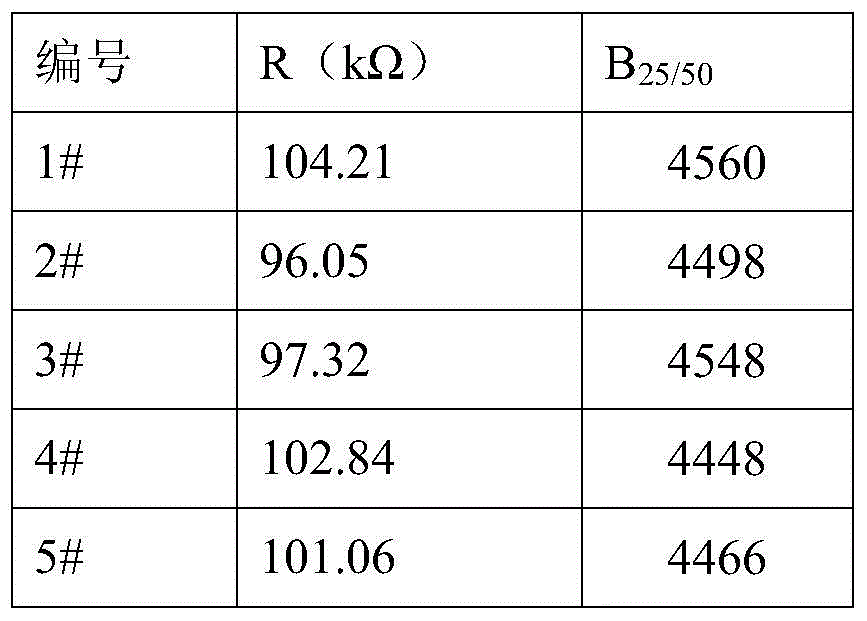

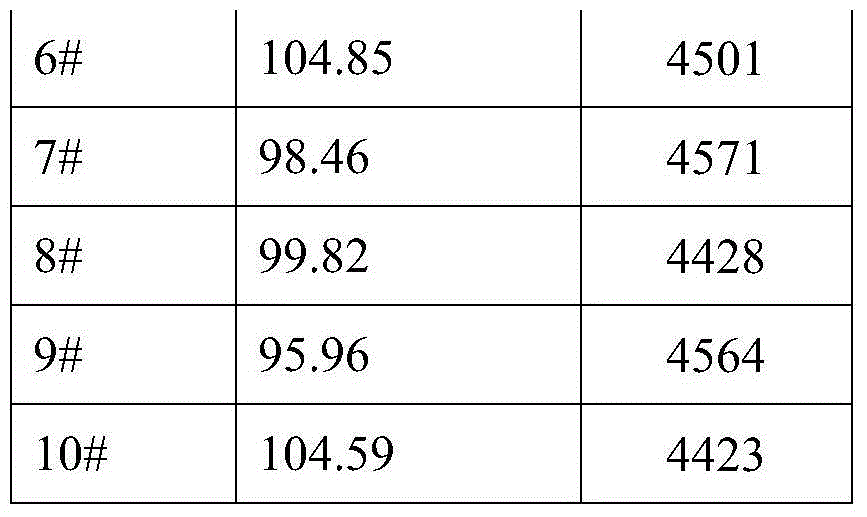

[0028] Example 1: Mix Co3O4, MnO2, Cr2O3, and Y2O3 powders in a proportion (molar percentage) of 40%: 45%: 11%: 4% to form transition metal oxide powders, and directly sinter the metal oxide powders to make Negative temperature coefficient thermistor chip. Wherein, the specific sintering temperature is 1200°C to 1270°C, and the time for maintaining the sintering temperature is between 3 and 9 hours. The thermistor chip obtained in this embodiment is assembled into a negative temperature coefficient thermistor, and the structure of the thermistor obtained is as follows: figure 1 shown. The specific preparation process is as follows: surround a layer of slurry containing glass powder around the NTC thermistor chip 1 except for both ends, and sinter the glass powder slurry to form a glass protective layer 2; Both ends of the thermistor chip 1 with the glass protective layer 2 are coated with a layer of electrode paste, the electrode paste is sintered, and electrodes 3 are forme...

Embodiment 2

[0029] Example 2: The components in this example are the same as those in Example 1, only the content of the components is different: the powders of Co3O4, MnO2, Cr2O3, and Y2O3 are in proportion (molar percentage) 34%: 60%: 5%: 1% Mixing is performed to form transition metal oxide powders. According to the formula, the thermistor chip is prepared, and then the thermistor is prepared. The preparation process is the same as that in Example 1, and the description is not repeated here. It is measured that the resistivity of the thermistor in this example is 3000Ω·mm, and the B value is 4050.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com