Fermentation mechanism for the production of seedling cultivation nutrients

A nutrient and seedling technology, which is applied in the field of fermentation mechanism for the production of nutrient for seedling cultivation, can solve problems such as unreasonable control of fermentation temperature, influence on fermentation effect, cumbersome process, etc., and achieve the effects of reasonable structure, guaranteed fermentation effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

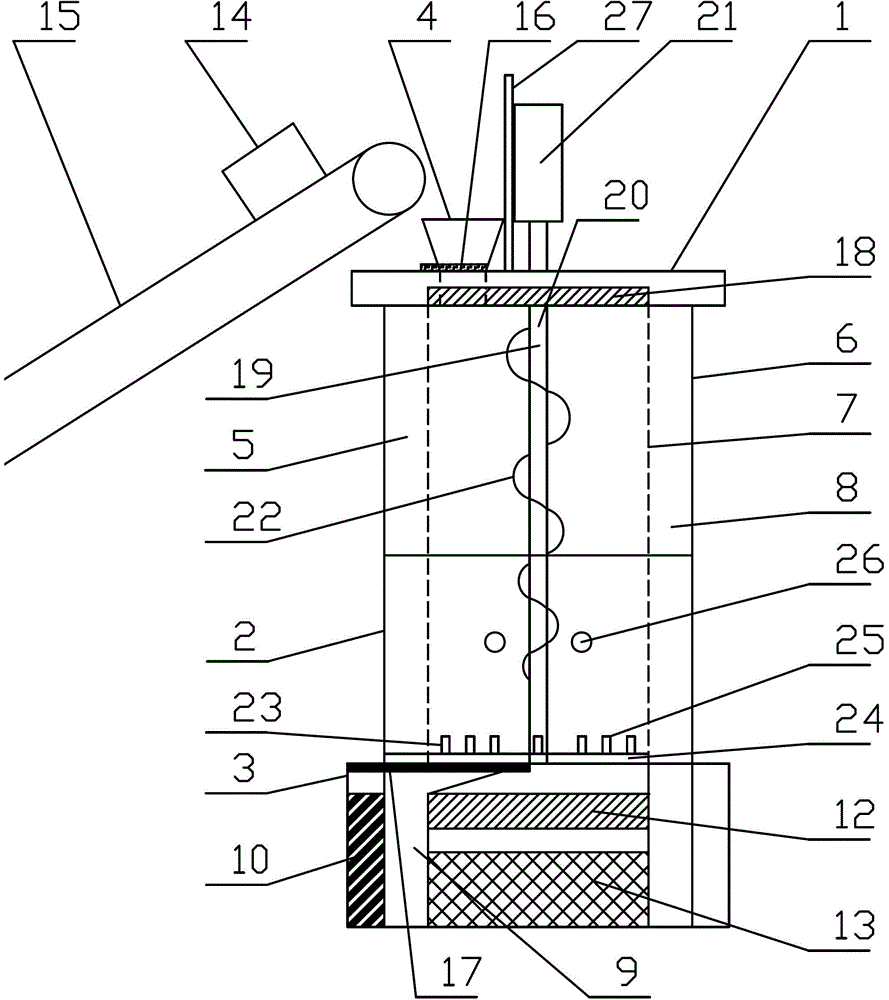

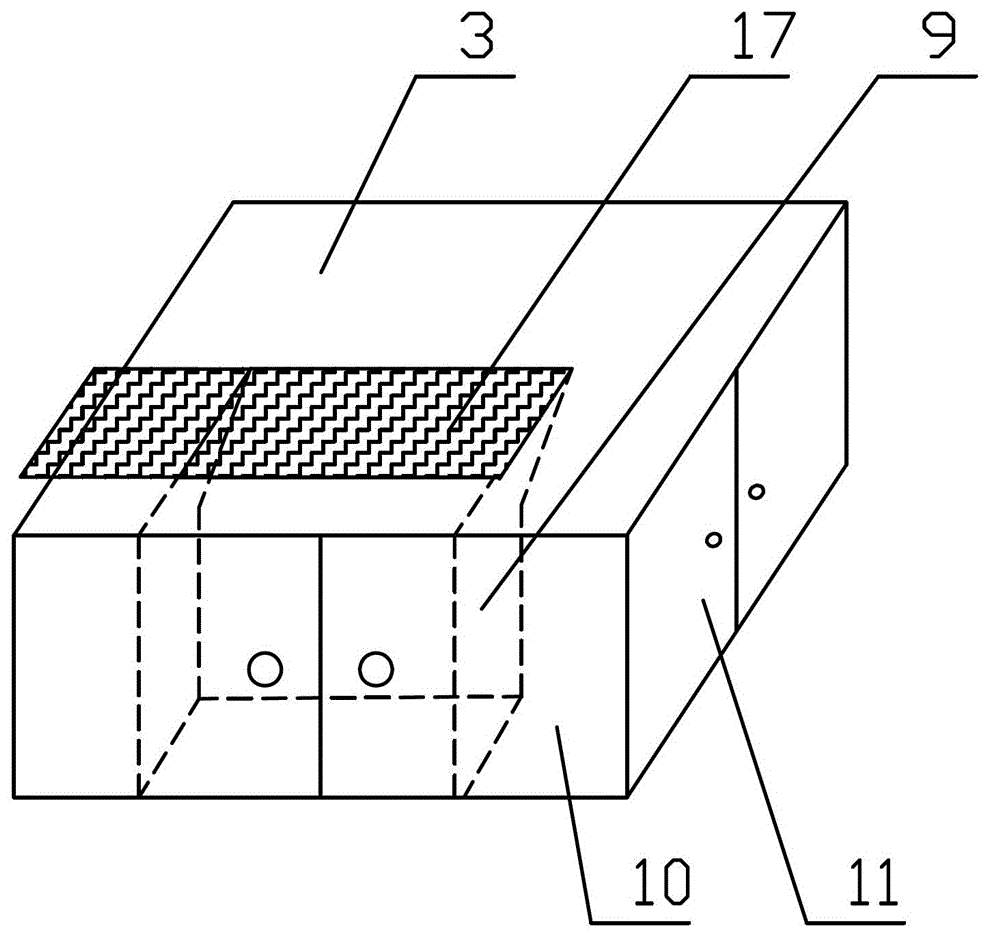

[0019] The invention provides a fermentation mechanism specially used for producing nursery stock cultivation nutrient, such as figure 1 As shown, it includes feeding section 1, fermentation section 2 and heating section 3. Wherein the feeding section 1 leads to the fermentation section 2 through the feeding hopper 4 in the shape of an inverted trapezoid. The device used in the fermentation stage 2 is a fermenter 5, which includes an outer shell 6, an inner tank 7 and a heat transfer channel 8 between them. Such as figure 2 As shown, the lower part of the fermenter 5 is provided with a discharge channel 9 leading to the discharge port 10 of the heating section 3 , and a discharge door 17 is provided at the discharge channel 9 . The outer periphery of the heating section 3 is provided with a discharge port 10 and an operating port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com