Method and device for using crude hydrocyanic acid to continuously produce D, L-2-hydroxy-4-methylthio-butyric acid microelement chelate

A technology of methylthiobutyric acid and trace elements, which is applied in the fields of sulfide preparation, organic chemistry, etc., can solve the problems of nutrient destruction, low density, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

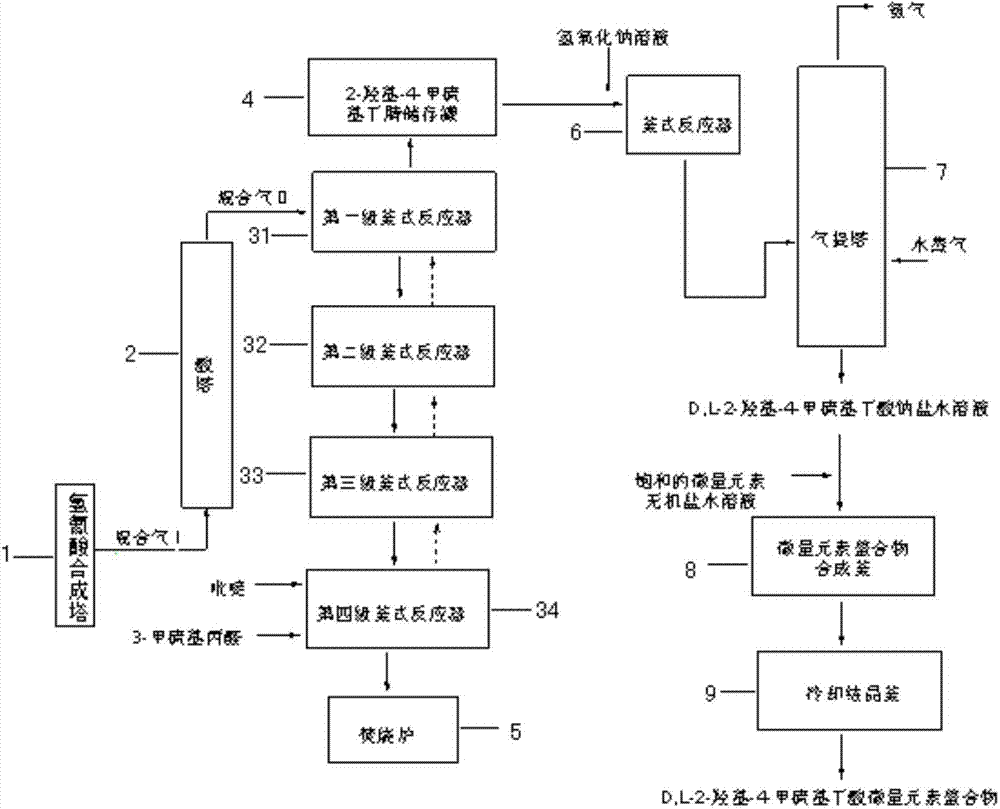

[0037] Such as figure 1 As shown, the device for producing D,L-2-hydroxy-4-methylthiobutyric acid trace element chelate is divided into three parts, which are respectively the device for continuous production of 2-hydroxy-4-methylthiobutyronitrile, D, L-2-hydroxy-4-methylthiobutyrate production equipment and D, L-2-hydroxy-4-methylthiobutyric acid trace element chelate production equipment.

[0038] The first part is a device for continuous production of 2-hydroxy-4-methylthiobutyronitrile (MMP-CN), including hydrocyanic acid synthesis tower 1, acid tower 2, four-stage series tank reactor, and low-temperature storage tank 4 ( 2-hydroxy-4-methylthiobutyronitrile storage tank) and incinerator 5. The hydrogen cyanide mixed gas I generated by the hydrogen cyanide synthesis tower 1 enters the acid tower 2 from the gas inlet at the bottom of the acid tower 2, and the hydrogen cyanide mixed gas II comes out from the top of the acid tower 2, and the acid tower 2 The air outlet at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com