Method for toughening and modifying polypropylene

A technology of toughening and modifying polypropylene, which is applied in the field of blending preparation, can solve problems such as loss of rigidity, achieve improved impact resistance, good mixing and dispersion effects, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

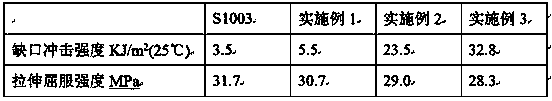

Examples

Embodiment 1

[0020] Carry out this test according to following raw material mass ratio:

[0021] 1) 100 parts of polypropylene (Shanghai Secco S1003);

[0022] 2) 5 parts of elastomer (Dow ENGAGE8842);

[0023] 3) 10 parts of ultra-high molecular weight polyethylene;

[0024] 4) 10 parts of low-density linear polyethylene (ExxonMobil 6101XR);

[0025] 5) Antioxidant 0.1 (Sinopharm 1010);

[0026] Antioxidant 0.1 (Sinopharm 168);

[0027] 6) Lubricant 1 (Sinopharm liquid paraffin).

[0028] Take 2000g of polypropylene, 100g of elastomer, 200g of ultra-high molecular weight polyethylene, and 200g of low-density linear polyethylene, dry it at 60°C for 4 hours, and then add it to a high-mixer for stirring; then add 2g of antioxidant 1010, 2g of anti-oxidant Oxygen agent 168 and 20g liquid paraffin continue to stir at high speed to make the materials mix evenly.

[0029] The obtained mixture is added to a twin-screw extruder for blending and extrusion, the temperature of the processing...

Embodiment 2

[0032] Carry out this test according to following raw material mass ratio:

[0033] 1) 100 parts of polypropylene (Shanghai Secco S1003);

[0034] 2) 15 parts of elastomer (Dow ENGAGE8842);

[0035] 3) 5 parts of ultra-high molecular weight polyethylene;

[0036] 4) 5 parts of low-density linear polyethylene (ExxonMobil 6101XR);

[0037] 5) Antioxidant 0.1 (Sinopharm 1010);

[0038] Antioxidant 0.1 (Sinopharm 168);

[0039] 6) Lubricant 1 (Sinopharm liquid paraffin).

[0040] Take 2000g of polypropylene, 300g of elastomer, 100g of ultra-high molecular weight polyethylene, and 100g of low-density linear polyethylene, dry it at 60°C for 4 hours, and then add it to a high-mixer for stirring; then add 2g of antioxidant 1010, 2g of anti-oxidant Oxygen agent 168 and 20g of liquid paraffin continue to stir at high speed to make the materials evenly mixed.

[0041] The obtained mixture is added to a twin-screw extruder for blending and extrusion, the temperature of the proces...

Embodiment 3

[0044] Carry out this test according to following raw material mass ratio:

[0045] 1) 100 parts of polypropylene (Shanghai Secco S1003);

[0046] 2) 20 parts of elastomer (Dow ENGAGE8842);

[0047] 3) 5 parts of ultra-high molecular weight polyethylene;

[0048] 4) 5 parts of low-density linear polyethylene (ExxonMobil 6101XR);

[0049] 5) Antioxidant 0.1 (Sinopharm 1010);

[0050] Antioxidant 0.1 (Sinopharm 168);

[0051] 6) Lubricant 1 (Sinopharm liquid paraffin).

[0052] Take 2000g of polypropylene, 400g of elastomer, 100g of ultra-high molecular weight polyethylene, and 100g of low-density linear polyethylene, dry it at 60°C for 4 hours, and then add it to a high-mixer for stirring; then add 2g of antioxidant 1010, 2g of anti-oxidant Oxygen agent 168 and 20g liquid paraffin continue to stir at high speed to make the materials mix evenly.

[0053] The obtained mixture is added to a twin-screw extruder for blending and extrusion, the temperature of the processing se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com