Smears for coating surface of vehicle body

A coating agent and vehicle technology, applied in the field of vehicles, to achieve the effect of high durability and excellent initial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

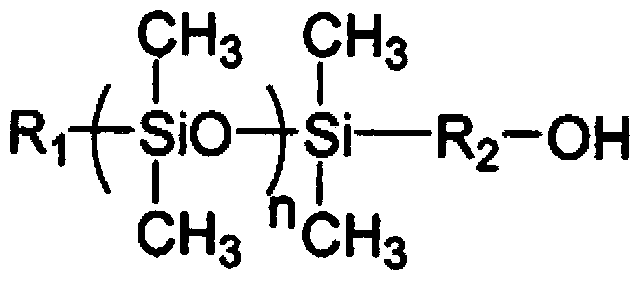

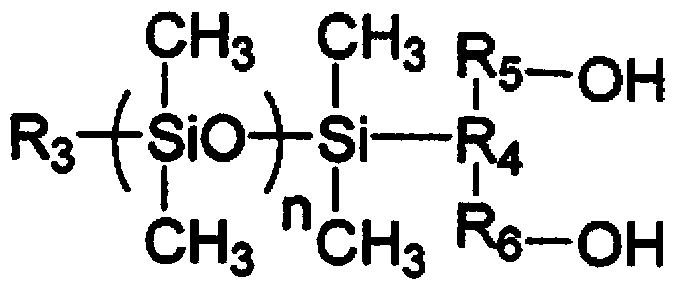

Method used

Image

Examples

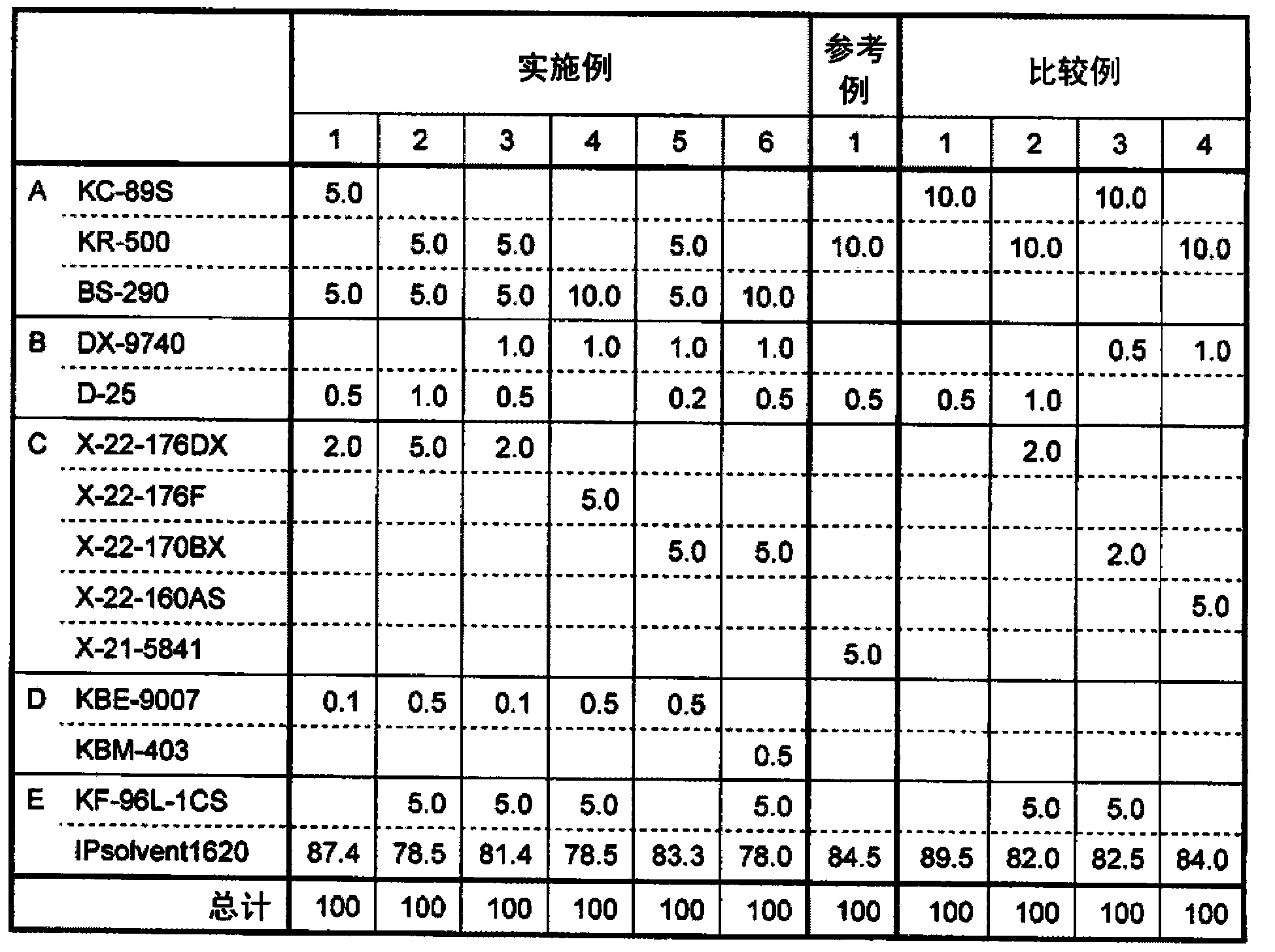

Embodiment 1

[0031] A coating agent consisting of the following silicone alkoxy oligomer, catalyst, modified silicone, silane coupling agent, and solvent was obtained. The above silicone alkoxy oligomer was KC-89S (manufactured by Shin-Etsu Chemical Co., Ltd.) 5.0 %, BS-290 (manufactured by Asahi Kasei Wacker Silicone) 5.0%, the above-mentioned catalyst is D-25 (titanium series, manufactured by Shin-Etsu Chemical Industry Co., Ltd.) 0.5%, the above-mentioned modified silicone is X-22-176DX (single-end dimethanol type, Shin-Etsu Chemical Co., Ltd.) 2.0%, the above-mentioned silane coupling agent is KBE-9007 (3-isocyanate propyltriethoxysilane, Shin-Etsu Chemical Co., Ltd.) 0.1%, and the above-mentioned solvent is IPsolvent1620 (Idemitsu Co., Ltd.) 87.4%.

Embodiment 2

[0033] A coating agent consisting of the following silicone alkoxy oligomer, catalyst, modified silicone, silane coupling agent, and solvent was obtained. The above silicone alkoxy oligomer was KR-500 (manufactured by Shin-Etsu Chemical Co., Ltd.) 5.0 %, BS-290 (manufactured by Asahi Kasei Wacker Silicone) 5.0%, the above-mentioned catalyst is D-25 (titanium series, manufactured by Shin-Etsu Chemical Industry) 1.0%, the above-mentioned modified silicone is X-22-176DX (single-terminal dimethanol type, Shin-Etsu Chemical Co., Ltd.) 5.0%, the above silane coupling agent is KBE-9007 (3-isocyanate propyltriethoxysilane, Shin-Etsu Chemical Co., Ltd.) 0.5%, the above solvent is KF-96L-1CS (Shin-Etsu Chemical Co., Ltd. ) 5.0%, IPsolvent1620 (manufactured by Idemitsu) 78.5%.

Embodiment 3

[0035] A coating agent consisting of the following silicone alkoxy oligomer, catalyst, modified silicone, silane coupling agent, and solvent was obtained. The above silicone alkoxy oligomer was KR-500 (manufactured by Shin-Etsu Chemical Co., Ltd.) 5.0 %, BS-290 (manufactured by Asahi Kasei Wacker Silicone) 5.0%, the above-mentioned catalyst is DX-9740 (aluminum series, manufactured by Shin-Etsu Chemical Co., Ltd.) 1.0%, D-25 (titanium series, produced by Shin-Etsu Chemical Co., Ltd.) 0.5%, the above-mentioned modification The silicone is X-22-176DX (single-end dimethanol type, manufactured by Shin-Etsu Chemical Co., Ltd.) 2.0%, and the above-mentioned silane coupling agent is KBE-9007 (3-isocyanate propyltriethoxysilane, manufactured by Shin-Etsu Chemical Co., Ltd.) 0.1% %, the above solvents are KF-96L-1CS (manufactured by Shin-Etsu Chemical Co., Ltd.) 5.0%, IPsolvent1620 (manufactured by Idemitsu Kogyo) 81.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com