Production process of abnormal acetate cloth tapes

A production process and technology of acetic acid cloth, applied in the production technology field of special-shaped acetic acid cloth tape, can solve the problems of inconvenient punching, high waste rate of finished products, easy falling of release paper, etc. Feeding and receiving, avoiding the effect of mutual friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

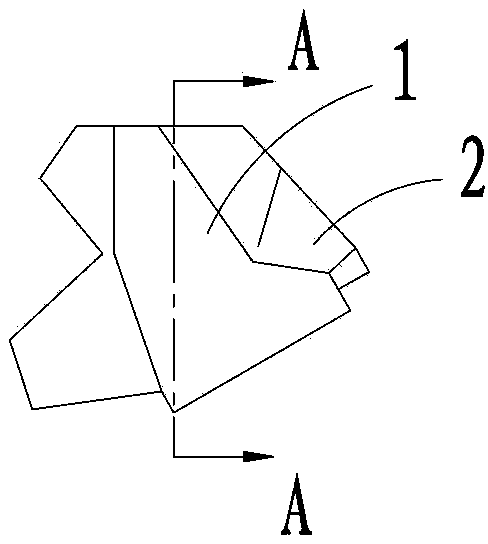

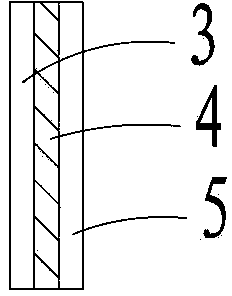

[0023] see figure 1 , figure 2 Shown is the special-shaped acetate cloth tape that needs to be obtained in this embodiment. The special-shaped acetate cloth tape includes a first sticking area 1 and a second sticking area 2. During use, the first sticking area 1 and the second sticking area 2 Paste on different parts in turn. The special-shaped acetate cloth tape usually includes an acetate cloth layer 3, an acrylic adhesive layer 4 pasted on one side surface of the acetate cloth layer 3, and the acrylic adhesive layer 4 is usually covered with a release paper layer or a release film 5 to protect The stickiness of the acrylic adhesive layer 4 can be pasted by tearing off the release paper layer or the release film 5 before use.

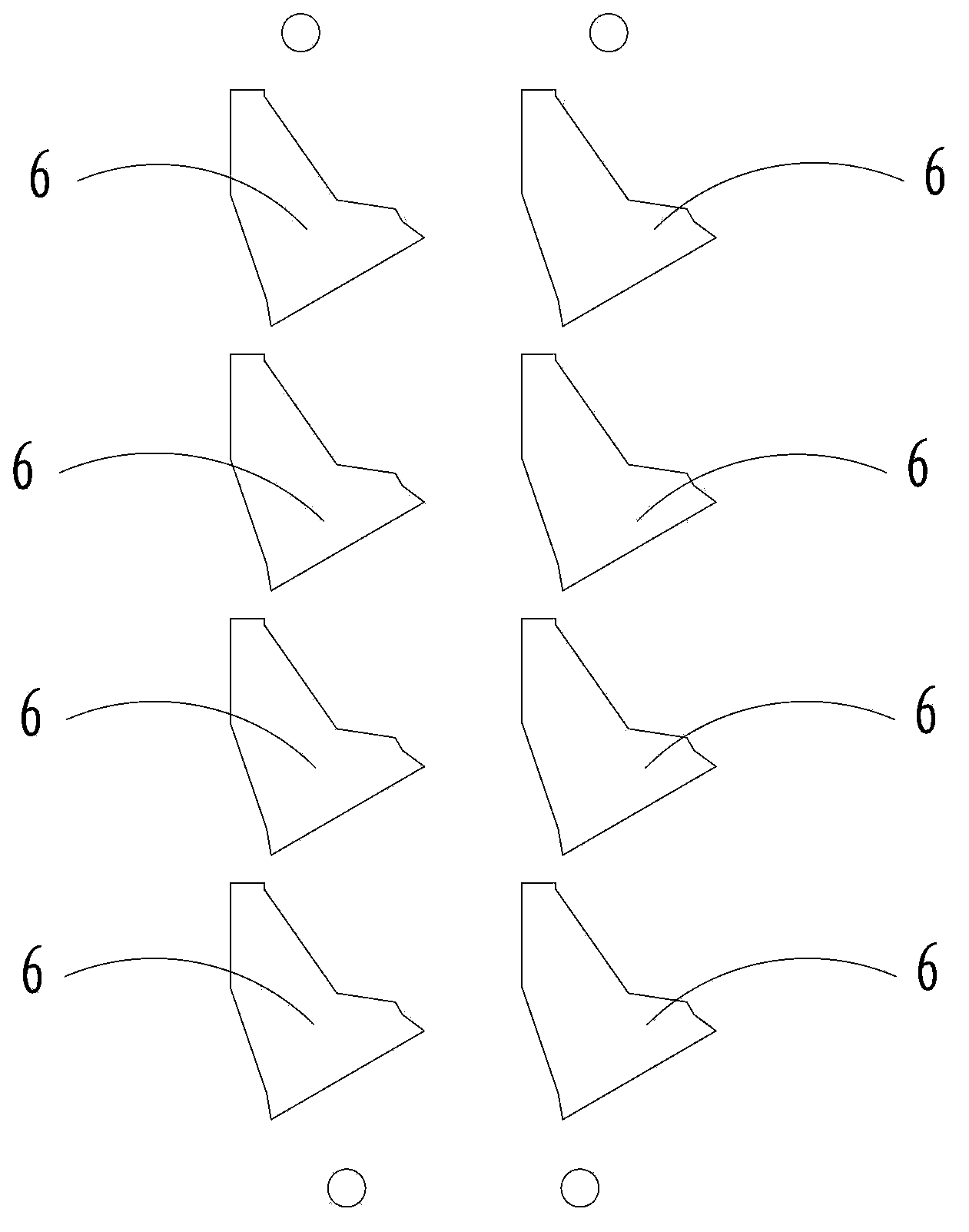

[0024] The blanking of this special-shaped acetate cloth adhesive tape is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com