Fruit and vegetable preparation for removing pesticide residues in fruits and vegetables and preparation method thereof

A preparation, fruit and vegetable technology, applied in the direction of chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problems of occupying space, destroying the environment, etc., and achieve the goals of avoiding damage, good emulsification, and increasing utilization value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 100 g of scallop shells were ground into coarse particles, calcined in a muffle furnace at 900° C. for 2 hours, cooled to room temperature, and passed through a 300-mesh sieve to obtain scallop shell powder. Add 0.5% β-cyclodextrin of scallop powder to the powder of scallop shell to make cleaning powder. Take 1g of powder and add 1L of water to make a solution. Soak 300g of apples in the solution for 10 minutes, take them out and rinse them with clean water. Take 2g of apple peel, and use the pesticide residue detection kit to detect the pesticide residues on the apple peel according to the national recommended standard method of GB / T5009.199-2003. The pesticide removal rate can reach 91%-93%, which is more than 10% higher than that of ordinary water cleaning. There is no difference in the taste of apples compared with those washed with ordinary water.

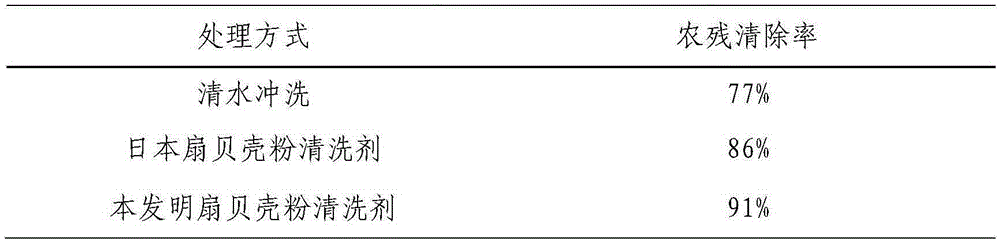

[0023] Table 1 Pesticide residue removal rate on apple surface

[0024]

Embodiment 2

[0026] 100 g of scallop shells were ground into coarse particles, calcined in a muffle furnace at 900° C. for 2 hours, cooled to room temperature, and passed through a 300-screen sieve to obtain scallop shell powder. Add 0.5% starfish saponin and 0.5% sodium alginate to the scallop powder to make cleaning powder. Take 4g of powder and add 2L of water to make a solution. Soak 500g of grapes in the solution for 20 minutes, take it out and rinse with water. Take 2g of grape skins, and use the pesticide residue detection kit to detect pesticide residues on grape skins according to the national recommended standard method of GB / T5009.199-2003. The pesticide removal rate can reach 91%-93%, which is more than 10% higher than that of ordinary water cleaning. There is no difference in the eating taste of grapes compared with those washed with ordinary water.

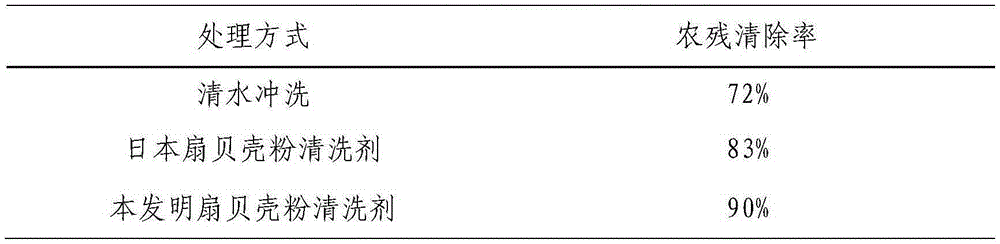

[0027] Table 2 Grape Surface Pesticide Residue Removal Rate

[0028]

Embodiment 3

[0030] 100 g of scallop shells were ground into coarse particles, calcined in a muffle furnace at 900° C. for 2 hours, cooled to room temperature, and passed through a 300-screen sieve to obtain scallop shell powder. Add 1% β-cyclodextrin and 1% sodium alginate to the scallop powder to prepare cleaning powder. Take 1g of powder and add 2L of water to prepare a solution. Soak 500g of Chinese cabbage in the solution, heat it on low heat for 10 minutes, take it out and rinse it with clean water. Take 2 g of cabbage leaves, and use the pesticide residue detection kit to detect the pesticide residues on the cabbage leaves according to the GB / T5009.199-2003 national recommended standard method. The test results show that the pesticide removal rate on the cabbage leaves can reach 93%-95%, which is more than 10% higher than that of ordinary clean water. There is no difference in the taste of cabbage compared with ordinary water washing.

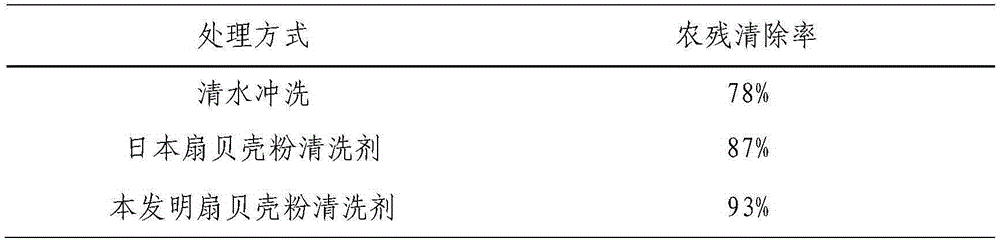

[0031] Table 3 Pesticide residue removal ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com