Method for controlling etching speed of aluminum and its alloy

A technology of etching speed and control method, which is applied in the field of etching speed control of aluminum and its alloys, can solve the problems of high disposal cost, short service life of etching solution, high production cost, etc., so as to reduce disposal cost, increase service life and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

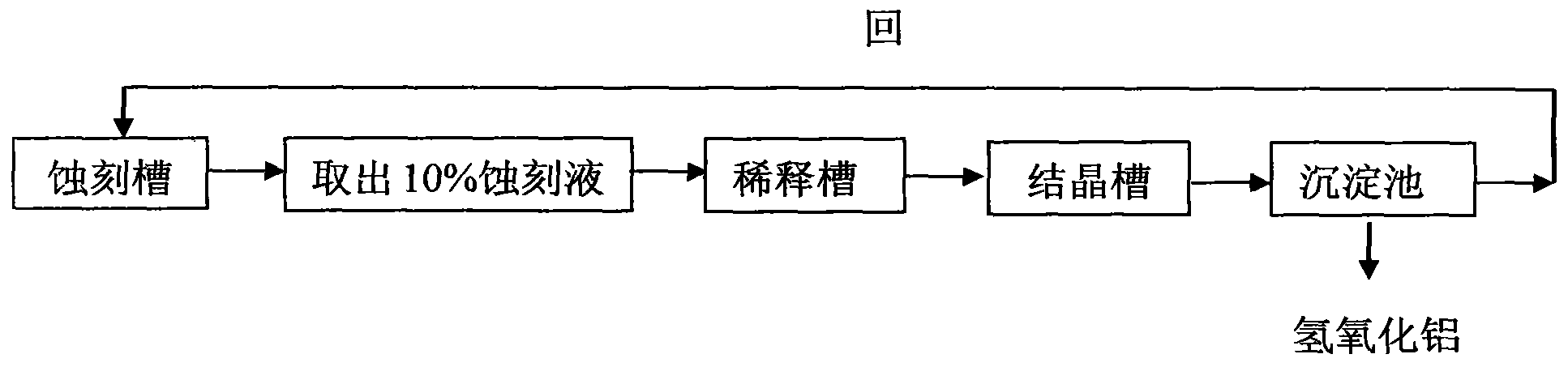

[0034] The present invention utilizes NaAlO 2 Under the condition of appropriate amount of water, Al(OH) crystallizes out 3 , so that the aluminum ions in the etching solution are controlled within the process range (the concentration of aluminum ions is 35-65g / L), on the one hand, it ensures the stability of the etching speed of aluminum and its alloys, and on the other hand, it prolongs the service life of the etching solution by more than 5 times.

[0035] Below in conjunction with specific embodiment, further illustrate the present invention.

[0036] A method for controlling the etching rate of aluminum and its alloys, characterized in that it comprises the following steps:

[0037] step one,

[0038] Take out about 10% of the total amount of etching solution from the etching tank; the etching tank contains an etching solution volume of 30m 3 -80m 3 , the etching solution includes sodium hydroxide: 140-170g / L, sodium sulfide: 13-18g / L, triethanolamine 38-45g / L, alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com