Shock isolation layer containing mixture formed by glass bead mortar, glass beads and fine sand and construction method thereof

A glass bead and mixture technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as poor seismic performance of buildings, and achieve the effects of easy repair, simple construction, and economical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

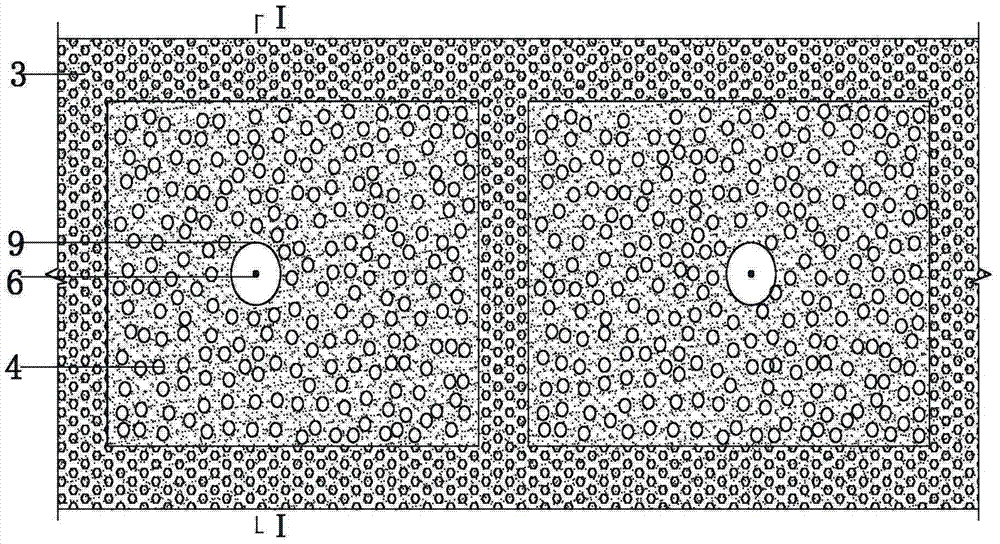

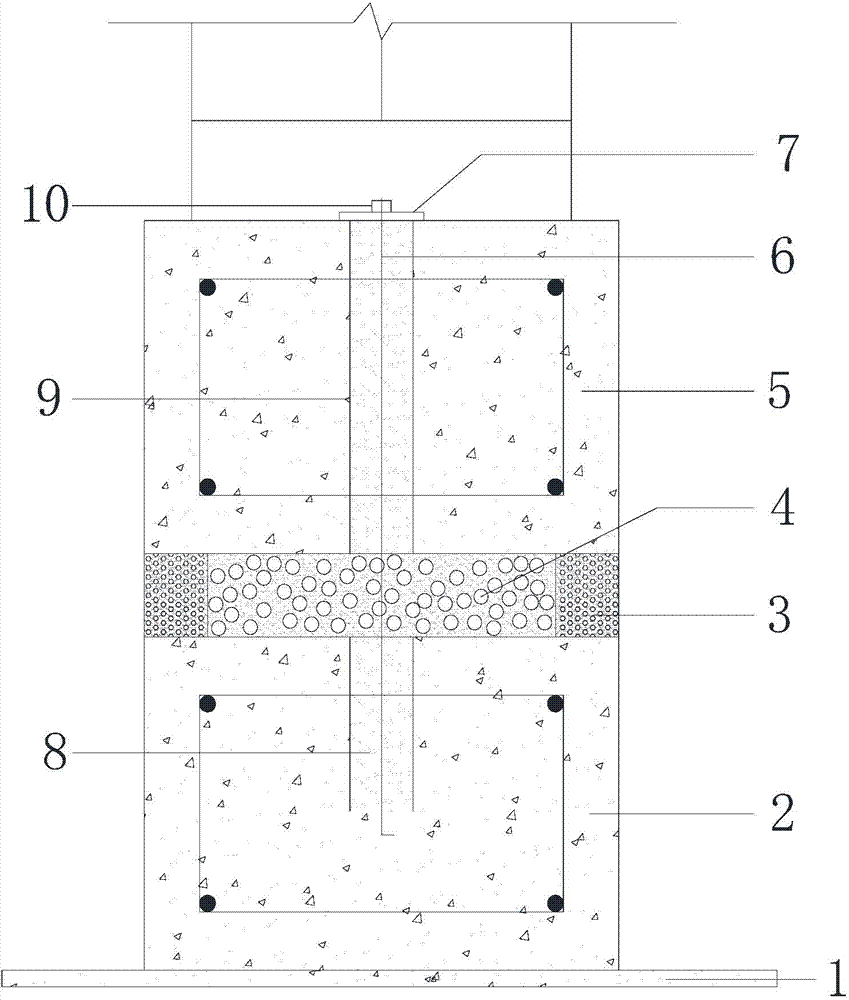

[0029] For a better understanding of the present invention, below in conjunction with the attached figure 1 And attached figure 2 The content of the present invention is further clarified.

[0030] Such as figure 1 and figure 2 , a shock-isolation layer with glass bead mortar and a mixture of glass beads and fine sand, including a plain concrete cushion 1, a lower foundation beam 2, a mixed mortar mixed with glass beads 3, a mixture of glass beads and fine sand 4, and an upper foundation beam 5. Limiting steel bar 6, steel backing plate 7, fine sand 8, steel casing 9, nut 10; plain concrete cushion 1 is laid on the foundation, and plain concrete cushion 1 is poured with lower foundation beam 2 and foundation beam 2 There are pre-embedded steel sleeves 9 and limit steel bars 6. The limit steel bars 6 are located in the pre-embedded steel sleeves 9, and are poured and anchored in the lower foundation beam 2. The steel sleeves 9 are filled with fine sand 8, and the lower fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com