Light composite prefabricated wallboard for house and preparation method thereof

A prefabricated wallboard, lightweight technology, used in manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of poor energy saving and structural safety, large energy waste, slow construction progress, etc., and achieve good social and economic benefits. Benefit, reduce waste of land resources, and reduce the effect of template usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

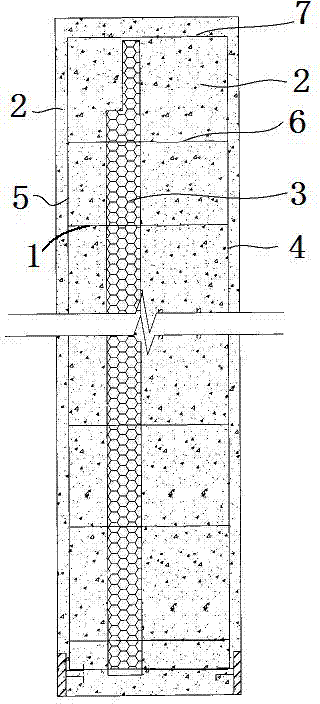

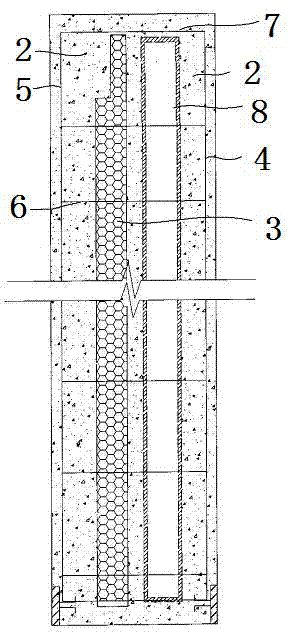

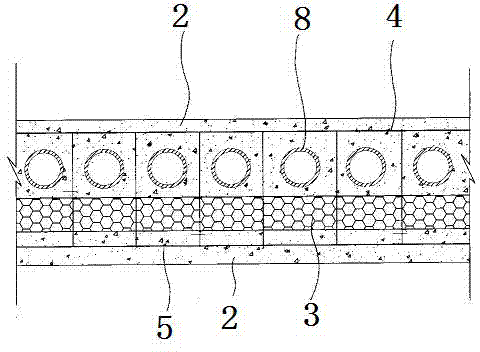

[0042] The structure of the lightweight composite prefabricated wallboard for houses proposed by the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Such as figure 1Shown is a structural schematic diagram of a lightweight composite prefabricated wall panel for a house. Its structure includes grid 1 and concrete 2, grid 1 includes insulation board 3 and the first reinforcement mesh sheet 4 and the second reinforcement mesh sheet 5 on both sides of insulation board 3, in the first reinforcement mesh sheet 4 and the second reinforcement Connecting bars 6 are arranged between the mesh sheets 5 , and an upper sheet 7 is arranged on the upper ends of the first steel mesh sheet 4 and the second steel mesh sheet 5 . In this way, each process can be carried out in an assembly line, which is convenient for production and concrete maintenance. When building a house, you only need to fix the required plates, and then pour the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com