Method of Reinforcement of Structure with Reinforced Concrete Frame with Ductile Column Energy Dissipator

A technology of reinforced concrete and reinforced structure, applied in building components, building structure, building maintenance, etc., can solve the problems of increasing the energy dissipation and shock absorption effect of the structure, lack of connection between old and new concrete, unable to form a whole, etc., so as to improve the bearing capacity. , flexible layout, small effect of using functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

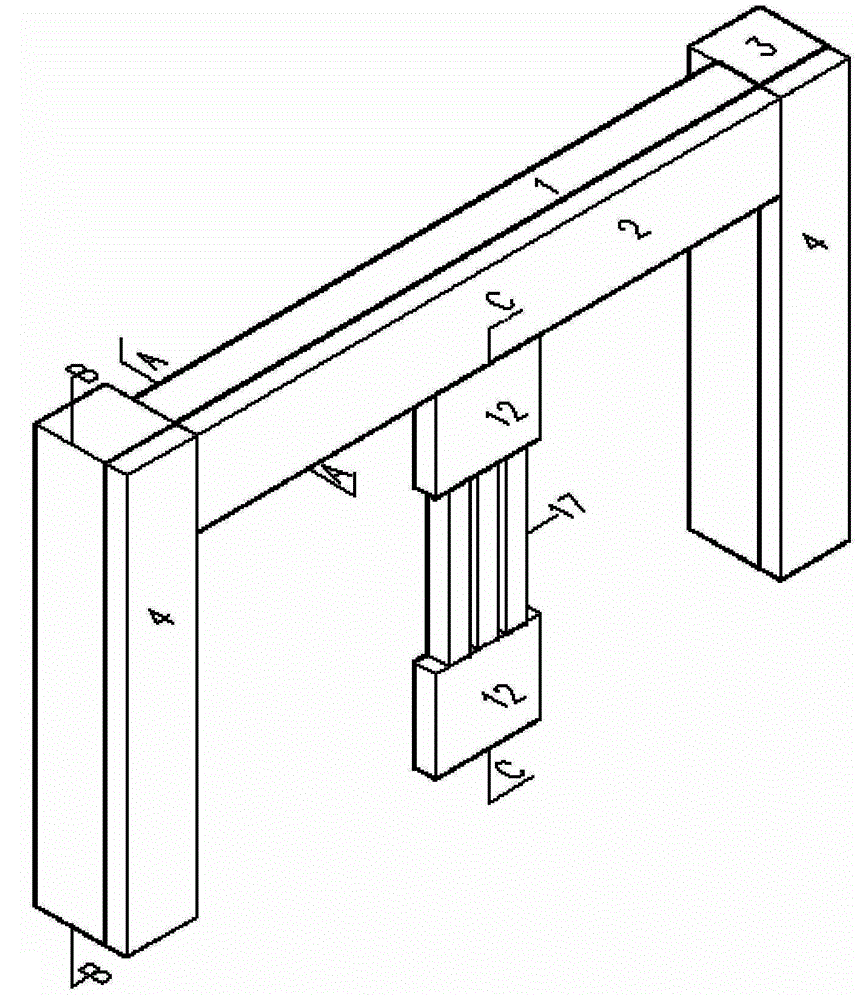

[0027] The specific construction method, taking the application in the frame beam as an example:

[0028] a. Design and manufacture

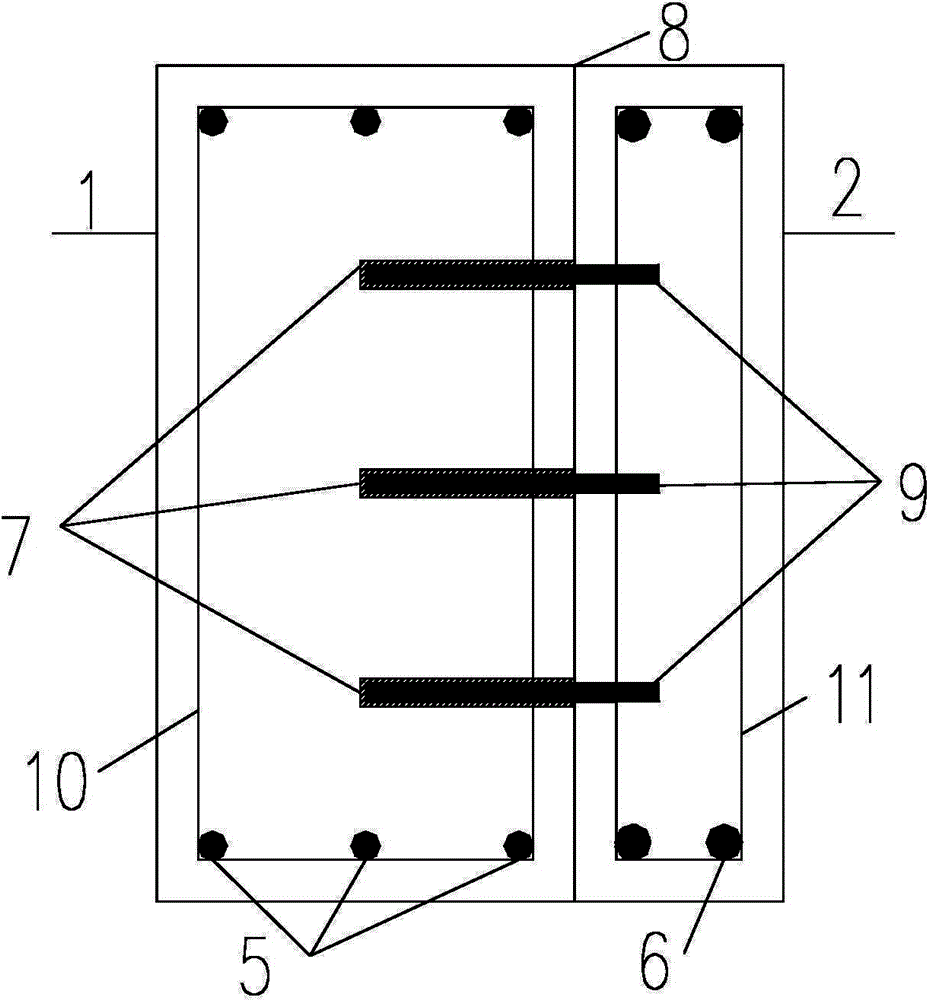

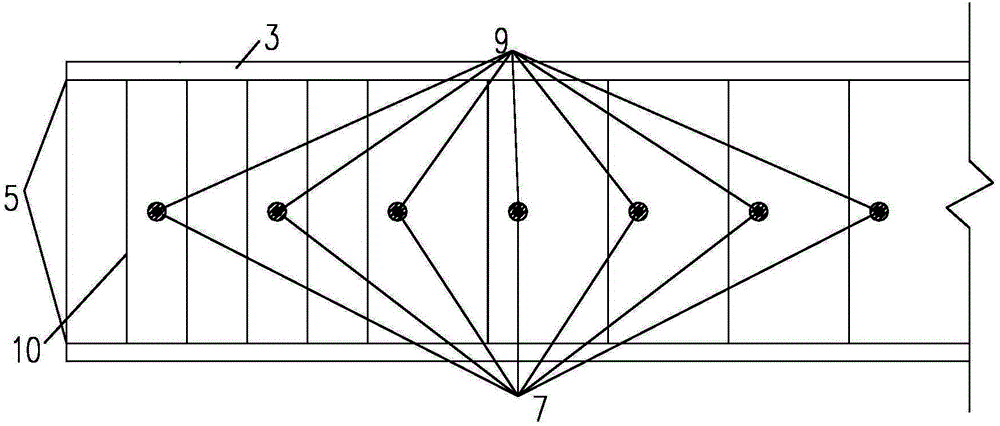

[0029] According to the section size of the original reinforced concrete frame beam 1, the newly added reinforced concrete frame beam 2 section is designed. According to the section and height of the newly added reinforced concrete frame beam 2, the size and reinforcement of the energy-dissipating column are designed. Select the type of glue for planting bars 7 and the diameter of the anchor bar 9, the depth of bars for planting, the distance between bars for planting, and the diameter of the drilled hole. Clean the concrete gouges on the surface of the original reinforced concrete frame beam at joint surface 8.

[0030] b.Anchoring

[0031] In the original reinforced concrete frame beam 1, holes are punched on the section along the length direction according to the parameters of the planting bar, the planting bar glue 7 is implanted, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com