Door frame splicing structure

A door frame and horizontal frame technology, applied in the field of door frame assembly structure, can solve the problems of easy knocking, scratching, jamming, pressing, complicated production, low production efficiency, etc., so as to reduce the cost of packaging and transportation, the production process is simple, and the occupation is reduced. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

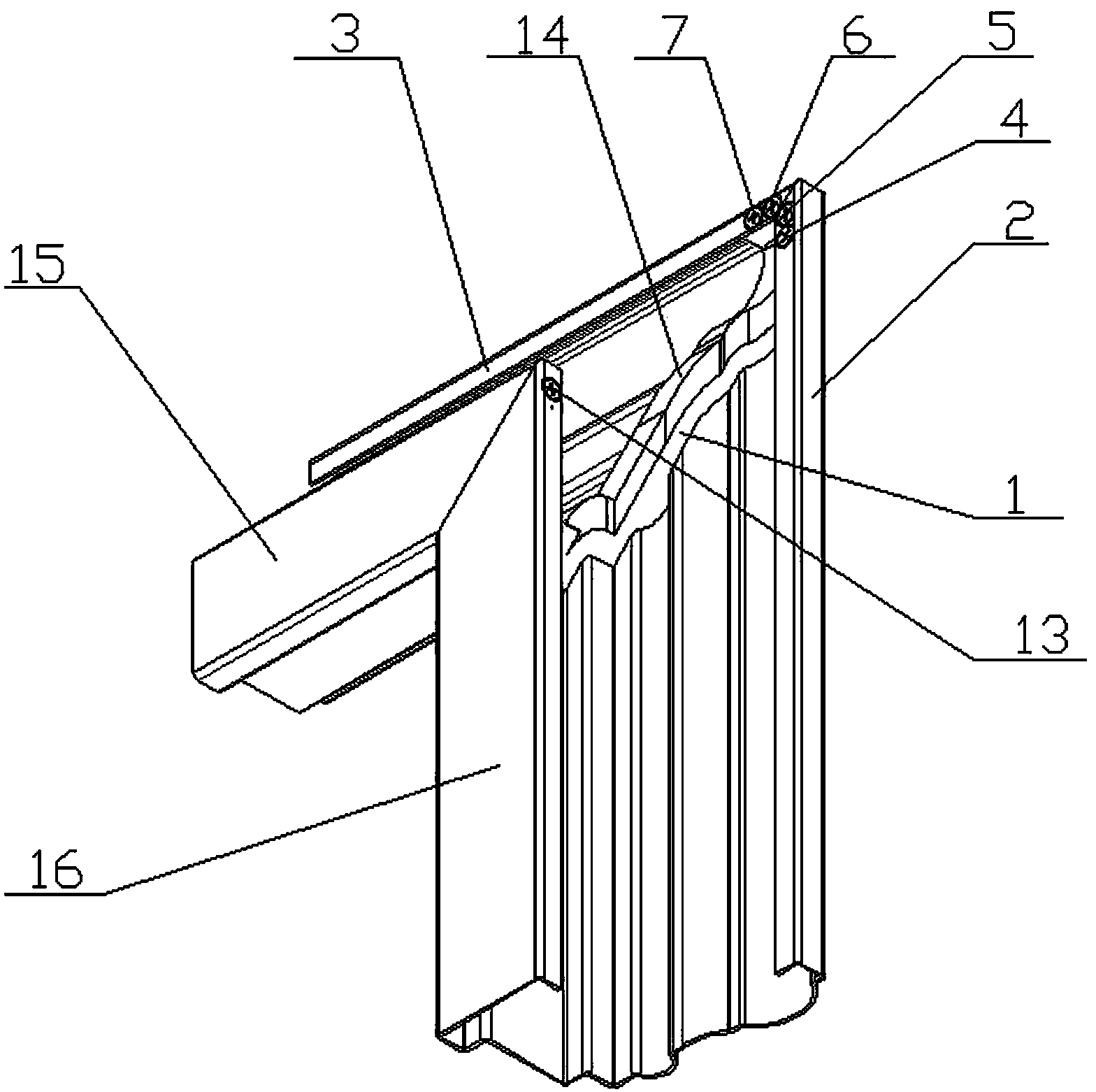

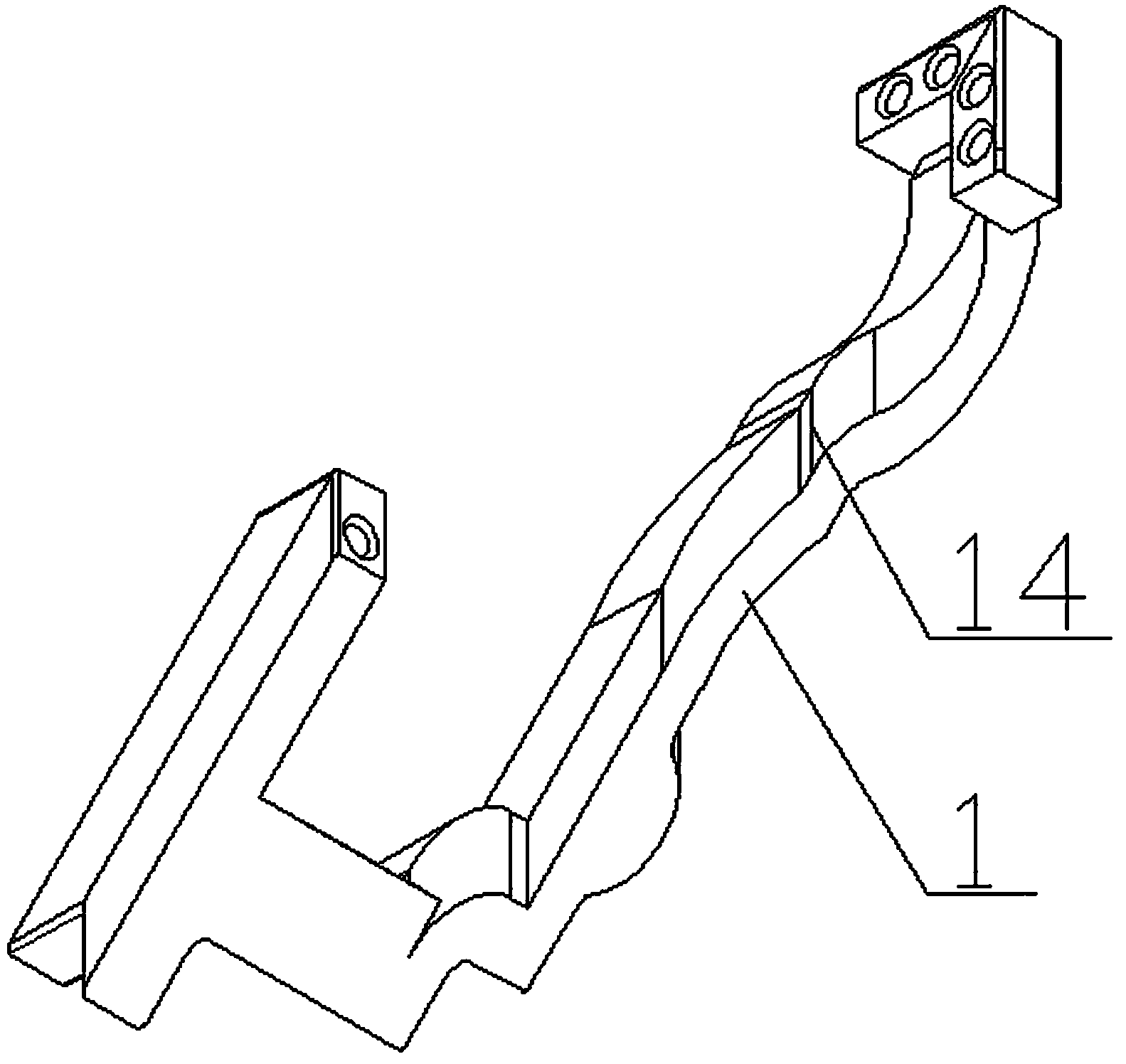

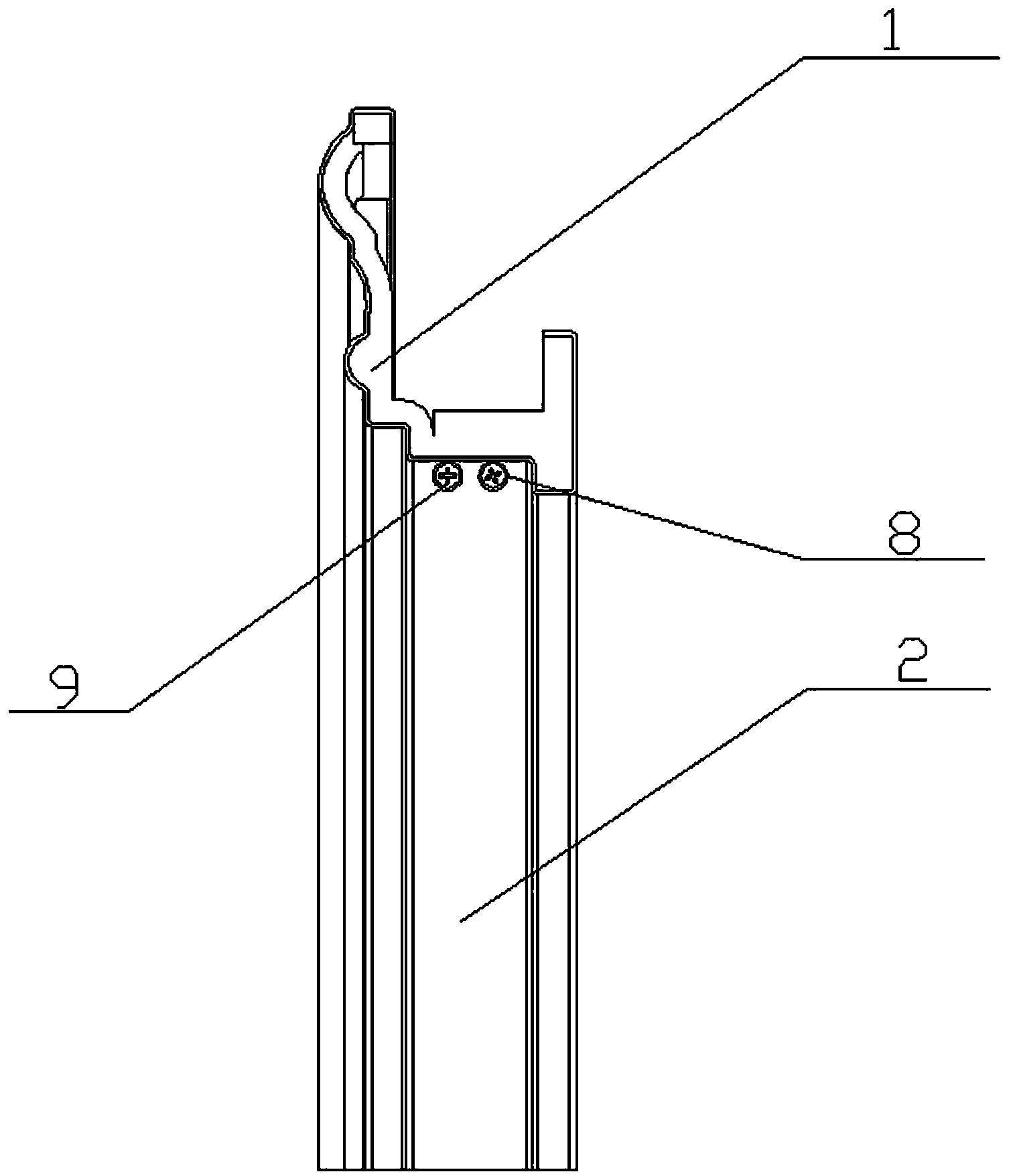

[0015] Such as Figure 1 to Figure 6 As shown, a kind of door frame assembly structure of the present invention, it comprises upper horizontal frame 3 and frame 2, and described frame 2 comprises the left frame and the right frame that are arranged symmetrically, and the frame type of upper horizontal frame 3 and frame 2 is the same, and upper horizontal frame The two ends of the frame 3 are set at a 45-degree cut angle, the upper end of the frame 2 is provided with a 45-degree cut angle matched with the 45-degree cut angle position of the upper horizontal frame 3, and the two ends of the upper horizontal frame 3 are at the upper end of the frame 2. Butt at the 45-degree cut angle position, the cavity at the docking position of the upper horizontal frame 3 and the frame 2 is provided with an attachment 1, the attachment 1 is located at the joint of the upper horizontal frame 3 and the frame 2, and the attachment 1 is a The side is in contact with the upper horizontal frame 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com