Gas injection device, coal underground gasification system and coal underground gasification method

A technology for underground gasification and coal, applied in coal gasification, underground mining, construction and other directions, can solve the problem of not realizing the effect of improving the composition of gas, and achieve the effects of reducing production costs, improving quality, and improving effective components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

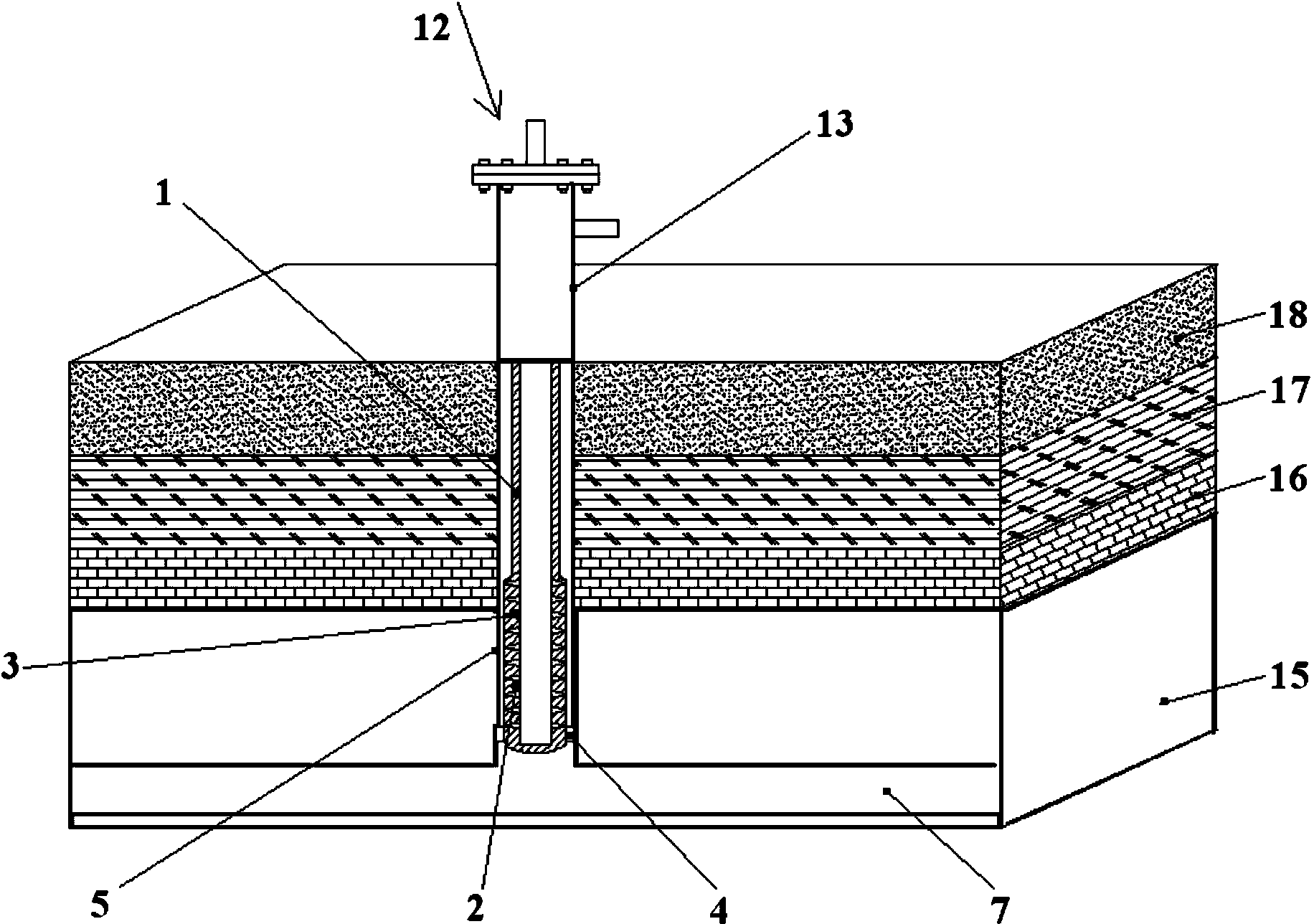

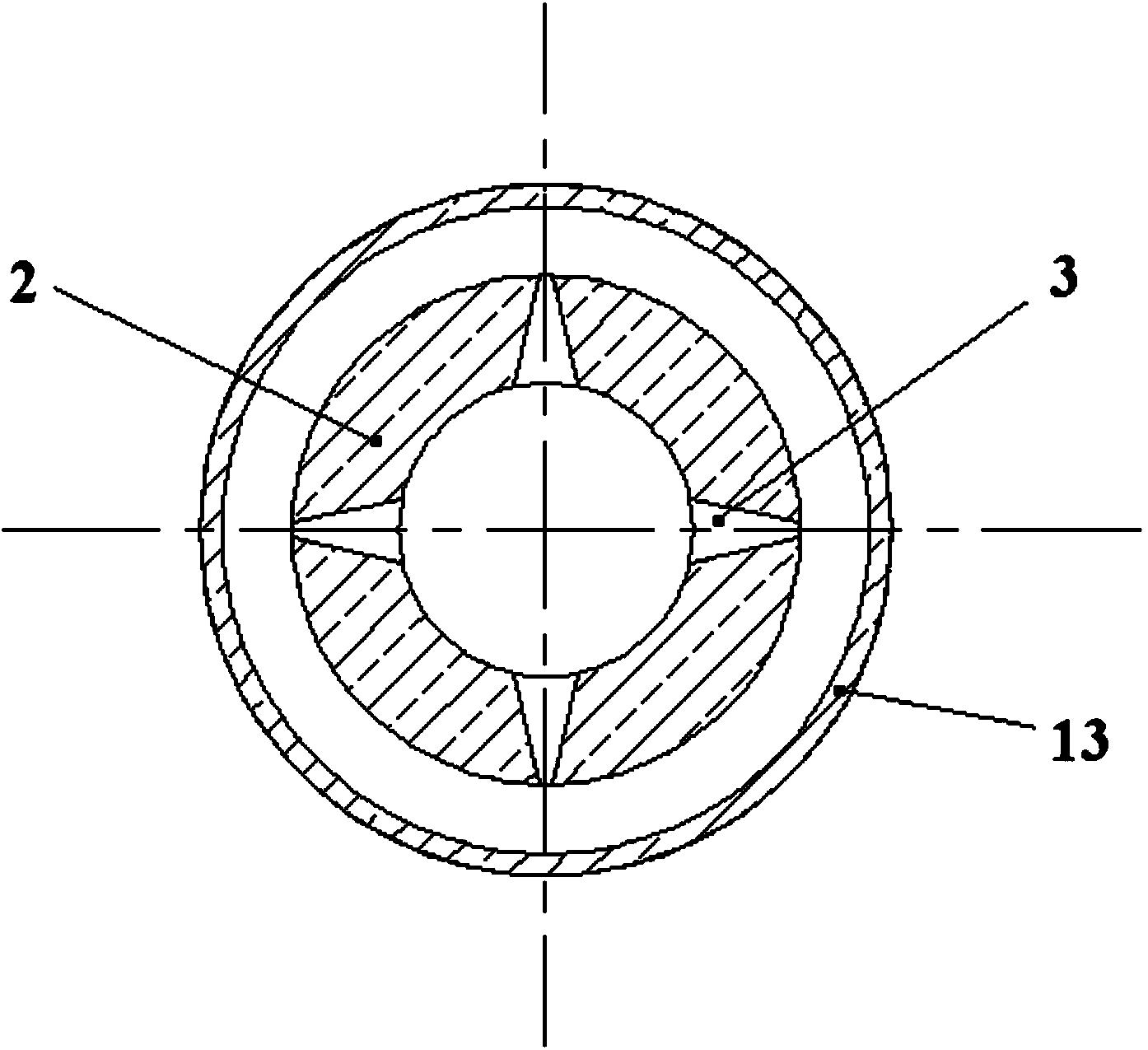

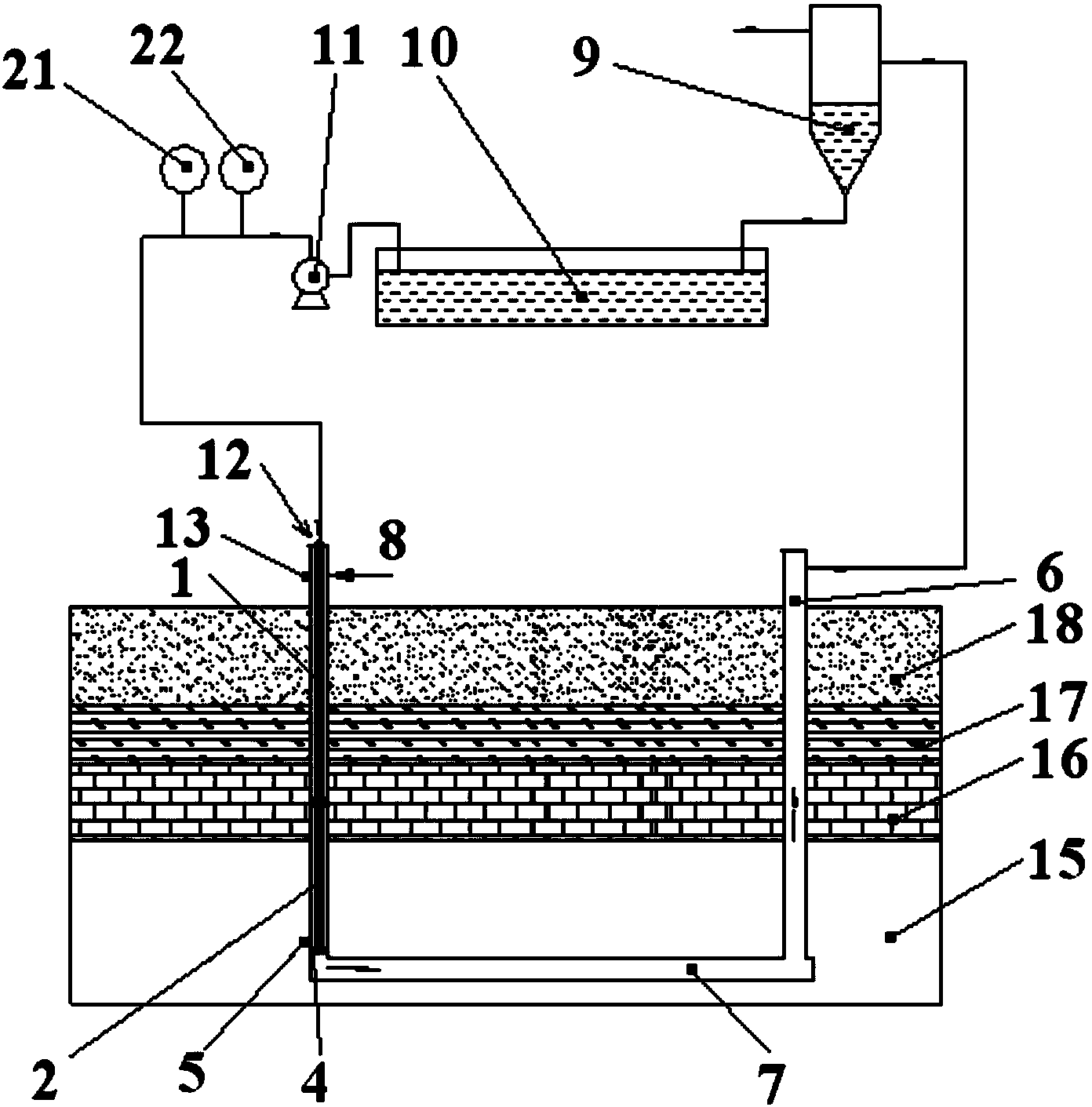

[0029] refer to figure 1 , an embodiment of the gas injection device 12 for underground coal gasification of the present invention, which includes: a water injection pipe 1 and a cylindrical atomizer 2, the two ends of which are respectively set as an open open end and a closed closed end, And nozzles are arranged on the wall around its axis, wherein the outlet of the water injection pipe 1 is in fluid communication with the open end of the cylindrical atomizer 2 .

[0030] Such as figure 1 Shown is that the gas injection device 12 is used in an exemplary formation, the formation descends from the ground to the upper cover layer 18, the aquifer layer 17, the roof rock layer 16 and the coal seam 18, and the air intake channel 5 is penetrated by the ground into the coal seam 15, and communicate with the gasification passage 7 in the coal seam 18, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com