Four-stroke engine without crankshaft and valves

A crankshaftless, four-stroke technology, applied in the field of four-stroke engines, can solve problems such as easy damage and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

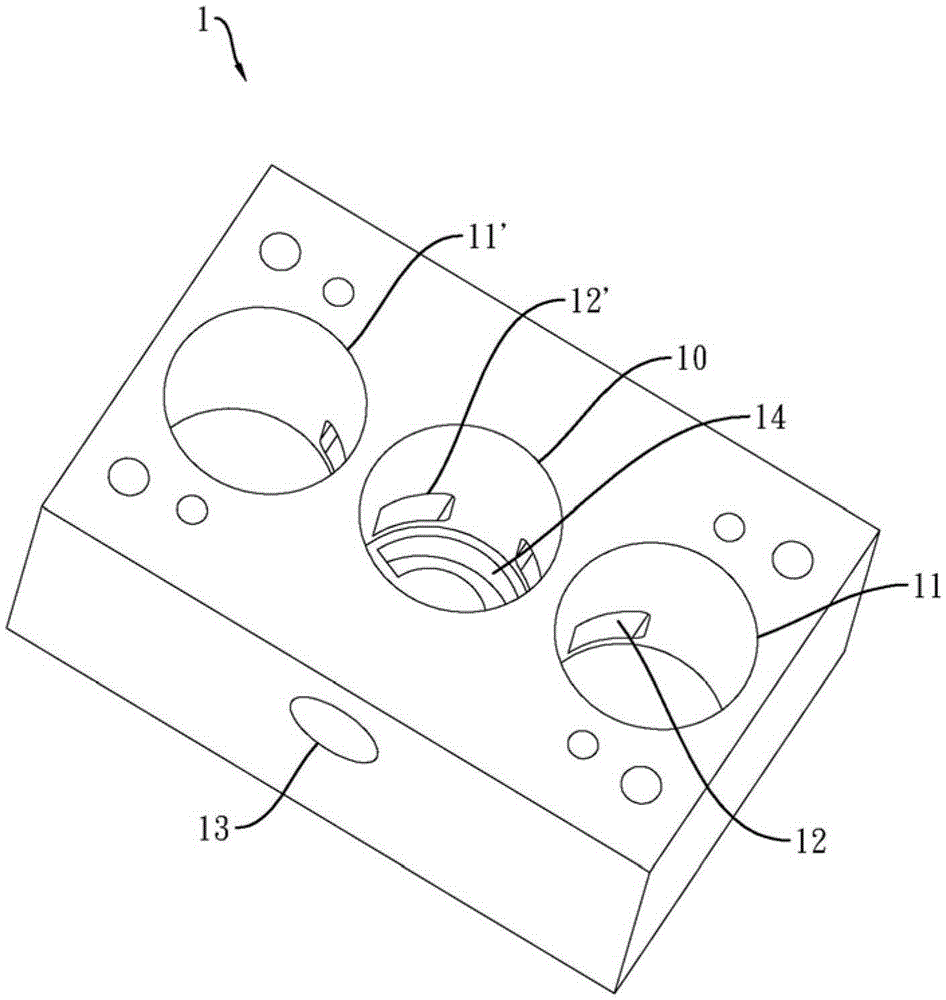

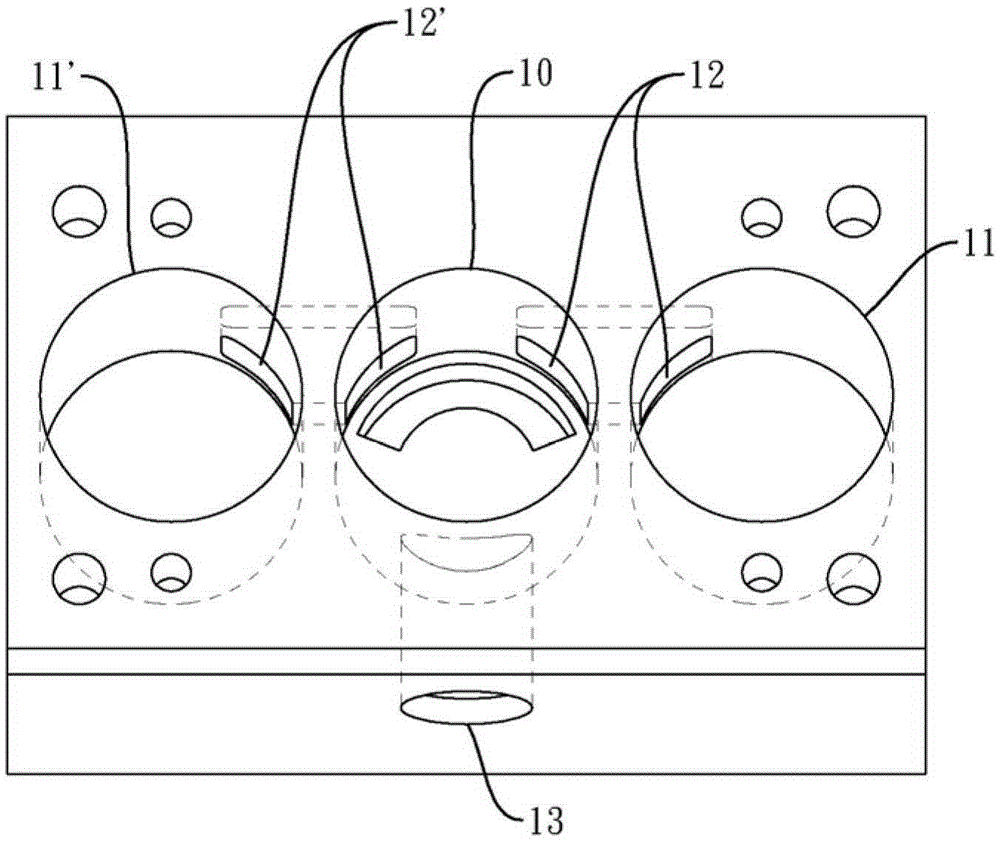

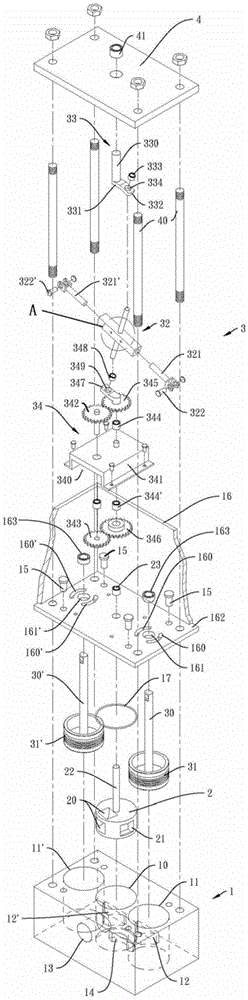

[0080] First, please also see Figure 1A , Figure 1B , Figure 2A , Figure 2B and image 3 As shown, the present invention mainly provides a four-stroke engine without a crankshaft and a valve. The engine mainly includes a base 1, an intake and exhaust valve 2, a base 16, a driving device group 3 and a top seat 4. The first One embodiment applies to diesel fuel, where:

[0081] base 1 (eg Figure 1A , Figure 1B and Figure 2A , Figure 2B shown), the base 1 is provided with intake and exhaust grooves 10 and cylinders 11, 11' arranged symmetrically in a ring with the intake and exhaust grooves 10 as the center point (the present invention takes two cylinders 11, 11' as For example), the inside of the base 1 is provided with intake and exhaust ports 12, 12' that communicate with the intake and exhaust grooves 10 and the cylinders 11, 11', and the side walls and bottom of the intake and exhaust grooves 10 are respectively provided with outlets that communicate with the o...

no. 2 example

[0102] Finally, please also see Figure 13 and Figure 14 shown by Figure 13 It can be seen that, in order to control the compression ratio of the cylinders 11, 11', the user can select the vertical lengths of the fixed rod 40 and the base 16 when installing the fixed rod 40 and the base 16, so as to determine the rotation through the shaft 33 in sequence. , the cross-shaped rotating rocker arm 32 and the push rod 30, 30' and the pistons 31, 31' indirectly connected with the top seat 4 respectively in the limit height D of the cylinder 11, 11' (wherein, the limit height D is based on a fixed rod 40 and the vertical length of the base 16), so that the cylinders 11, 11' have a variety of compression ratios, so that the engine can be used in the same engine in addition to being applicable to diesel fuel as described in the first embodiment. Gasoline fuel is suitable under the structure.

[0103] cooperate again Figure 14 It can be seen that if the cylinders 11 and 11' of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com