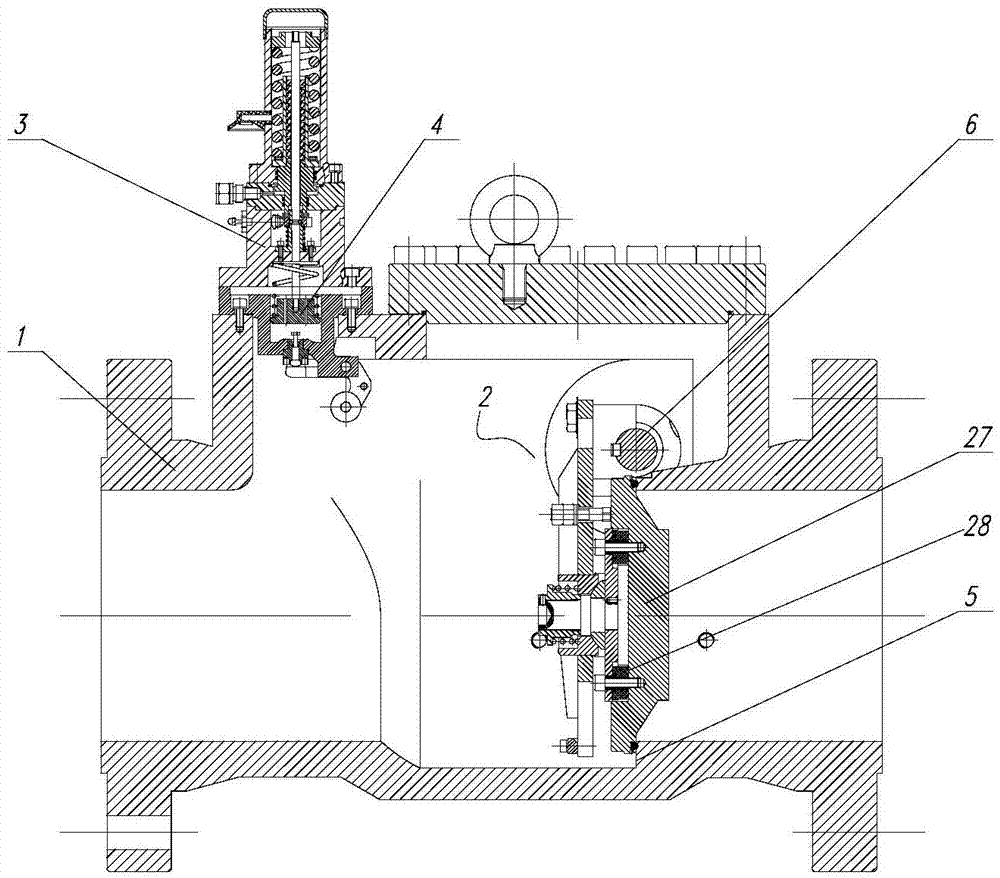

Swing axial-flow safety shut-off valve for natural gas

A safety cut-off valve, swing-type technology, applied in the direction of safety valve, lift valve, balance valve, etc., can solve the problems of reduced reliability, difficult installation, small pre-tightening force, etc., to achieve tight sealing surface and no protection destroyed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

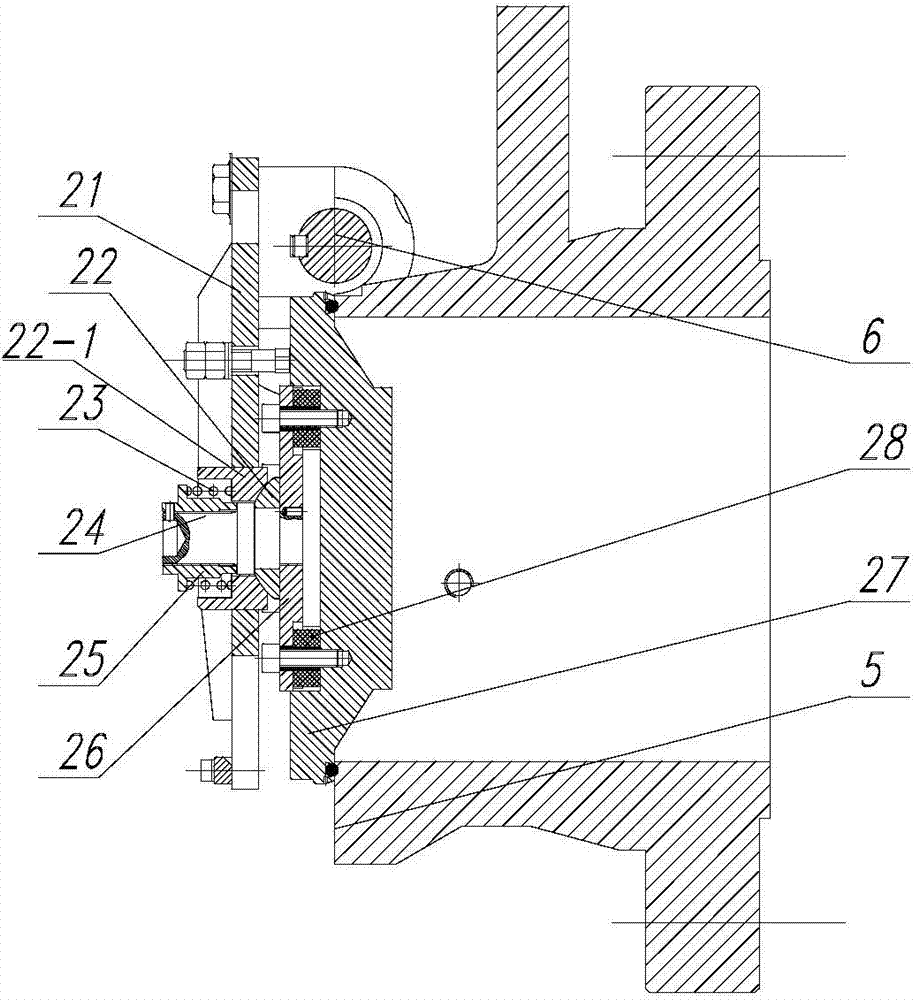

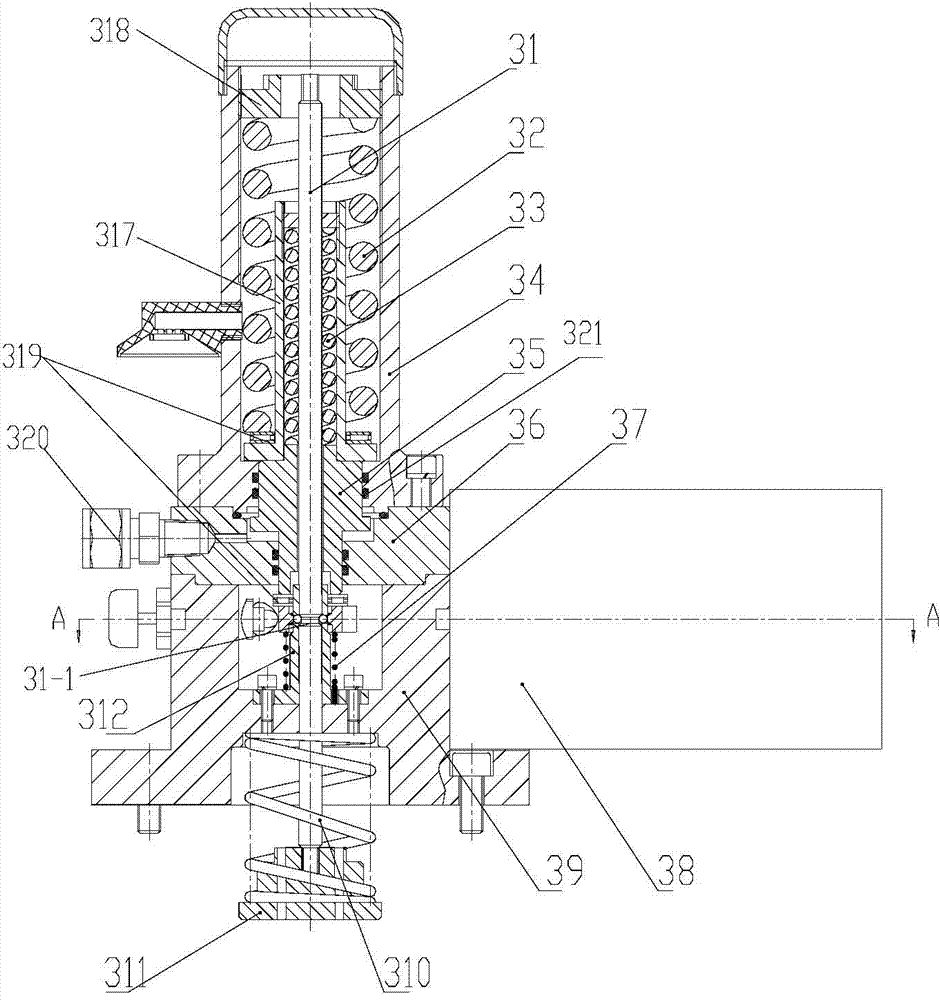

[0032]Referring to the accompanying drawings for details, the present invention provides a natural gas swing-type axial-flow safety cut-off valve, including a hand wheel 46, a valve seat 5, a sealing flap mechanism 2, a safety shut-off valve pilot 3, and a seal on the sealing flap mechanism. Turning plate 27 and sealing turning plate rotating shaft 6, described sealing turning plate comprises sealing turning plate connecting plate 21, buffer spring 23, sealing turning plate connection bolt 24, buffering spring seat 25 and connecting backing plate 26, described sealing turning plate A connecting backing plate is connected by bolts, and the center of the connecting backing plate is provided with a threaded hole, and the threaded hole is connected with a sealing flap connecting bolt, and the sealing flap connecting bolt is in the shape of a stepped shaft, and the sealing flap connecting bolt The left end is connected with a buffer spring seat, and a buffer spring is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com