Air supply system for large-volume air-cooled refrigerator and air-cooled refrigerator

A technology of air supply system and air-cooled refrigerator, which is applied in household refrigeration devices, applications, household appliances, etc., can solve the problems of reduced flow, large impact loss at inlet and outlet, and increased space occupied by the air supply system, so as to reduce space. size, avoiding impact losses, reducing the effect of airflow leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0058] In order to fundamentally improve the air circulation mode, the present invention adopts a centrifugal fan and cooperates with a reasonable air duct to replace the previous axial flow fan structure, which makes the air circulation in the refrigerator more reasonable, effectively reduces the energy loss of the flow channel, and reduces the aerodynamic noise.

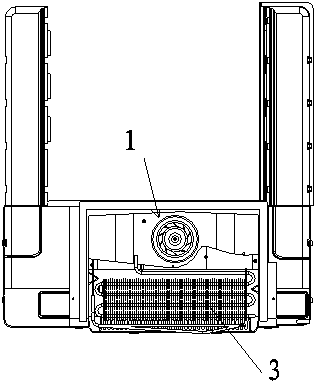

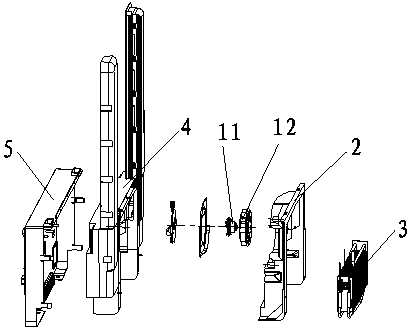

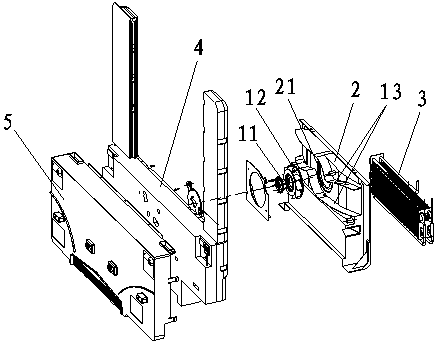

[0059] refer to Figure 1-3 As shown, an air supply system for a large-volume air-cooled refrigerator includes an air duct and a centrifugal fan 1. The centrifugal fan 1 adopts a centrifugal fan with two-way air outlets, and adopts a compact outer rotor structure, including a motor 11 and an impeller 12. And the volute 13, the air duct is a double volute tongue arc-shaped centrifugal air duct separated up and down, and the volute 13 is composed of the above-mentioned doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com