Energy-saving environment-protecting type hot air vegetable drying device

An energy-saving and environment-friendly drying device technology, applied in the direction of drying gas arrangement, drying solid materials, progressive dryers, etc., can solve the problems of no material turning mechanism, no use of waste heat, and unsatisfactory drying effect of vegetables, etc. value, the effect of improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

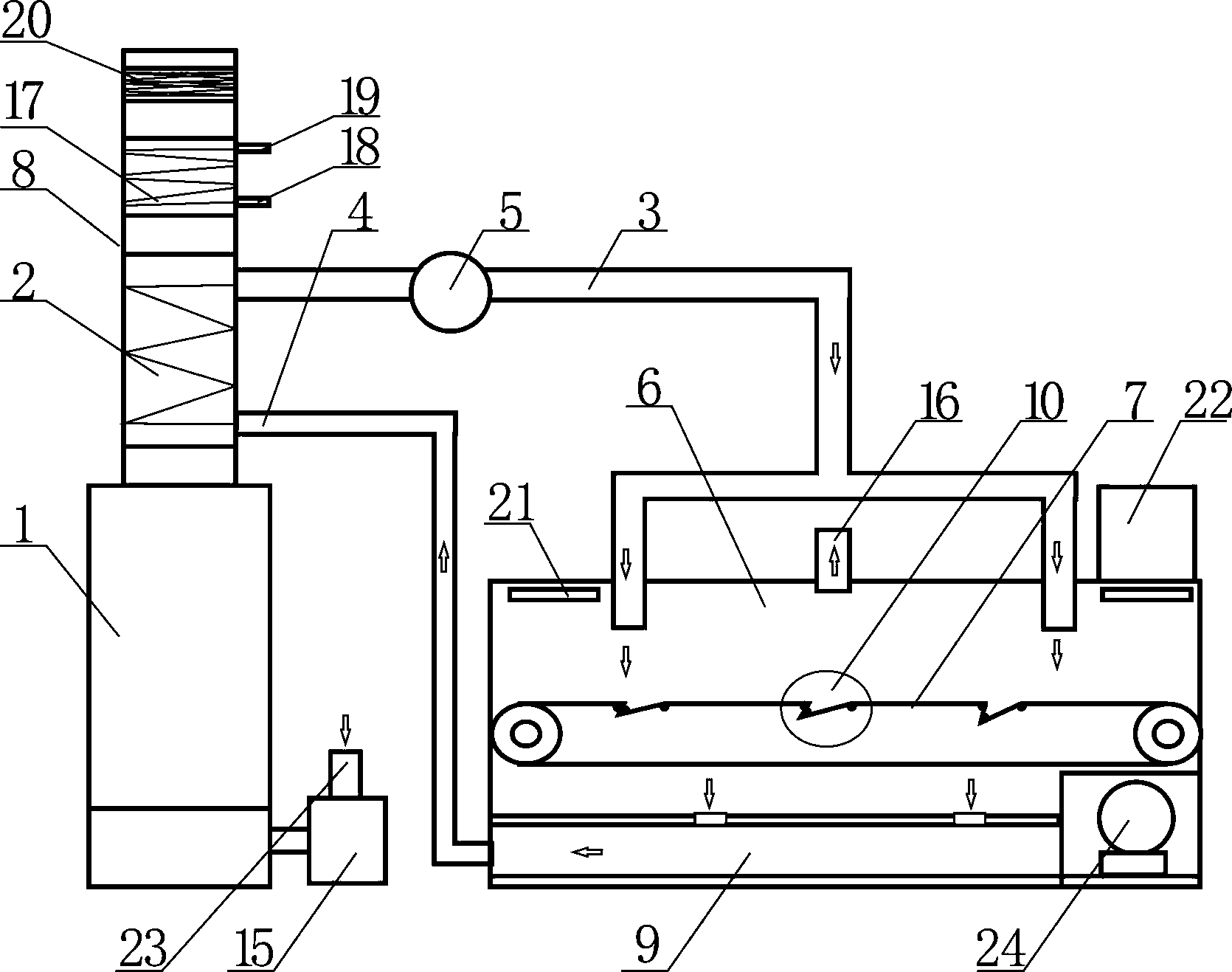

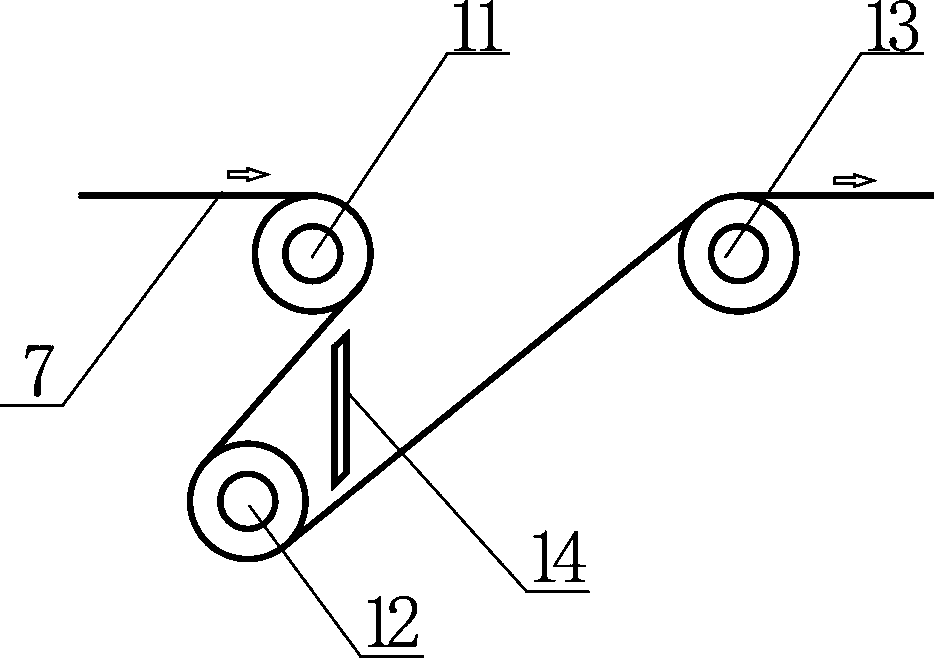

[0018] Such as figure 1 , 2 As shown, the energy-saving and environment-friendly hot air vegetable drying device is mainly composed of a furnace body 1, a heat exchanger 2, a hot air feeding pipe 3, a hot air return pipe 4, an exhaust fan 5, a hot air oven 6, and a conveyor belt powered by a motor 24. 7, the top of the body of furnace 1 is provided with a chimney 8, the heat exchanger 2 is arranged in the chimney 8, the air inlet end of the hot air feeding pipe 3 communicates with the heat exchanger 2, and the other end communicates with the hot air oven 6 The hot blast inlet at the top communicates, and one end of the hot blast return pipe 4 communicates with the hot blast return channel 9 at the bottom of the hot blast oven 6, and the other end communicates with the heat exchanger 2; the conveyor belt 7 is arranged in the hot blast oven 6, and the There are three material turning mechanisms 10 distributed at intervals on the conveyor belt 7, and the material turning mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com